Method for lowering influence on copper interconnection reliability from online WAT testing

A technology of copper interconnection and reliability, applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of thick oxide layer, dielectric material damage, dielectric The effect of reducing the reliability of copper interconnection, suppressing the formation of defects, and improving the interface bonding state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

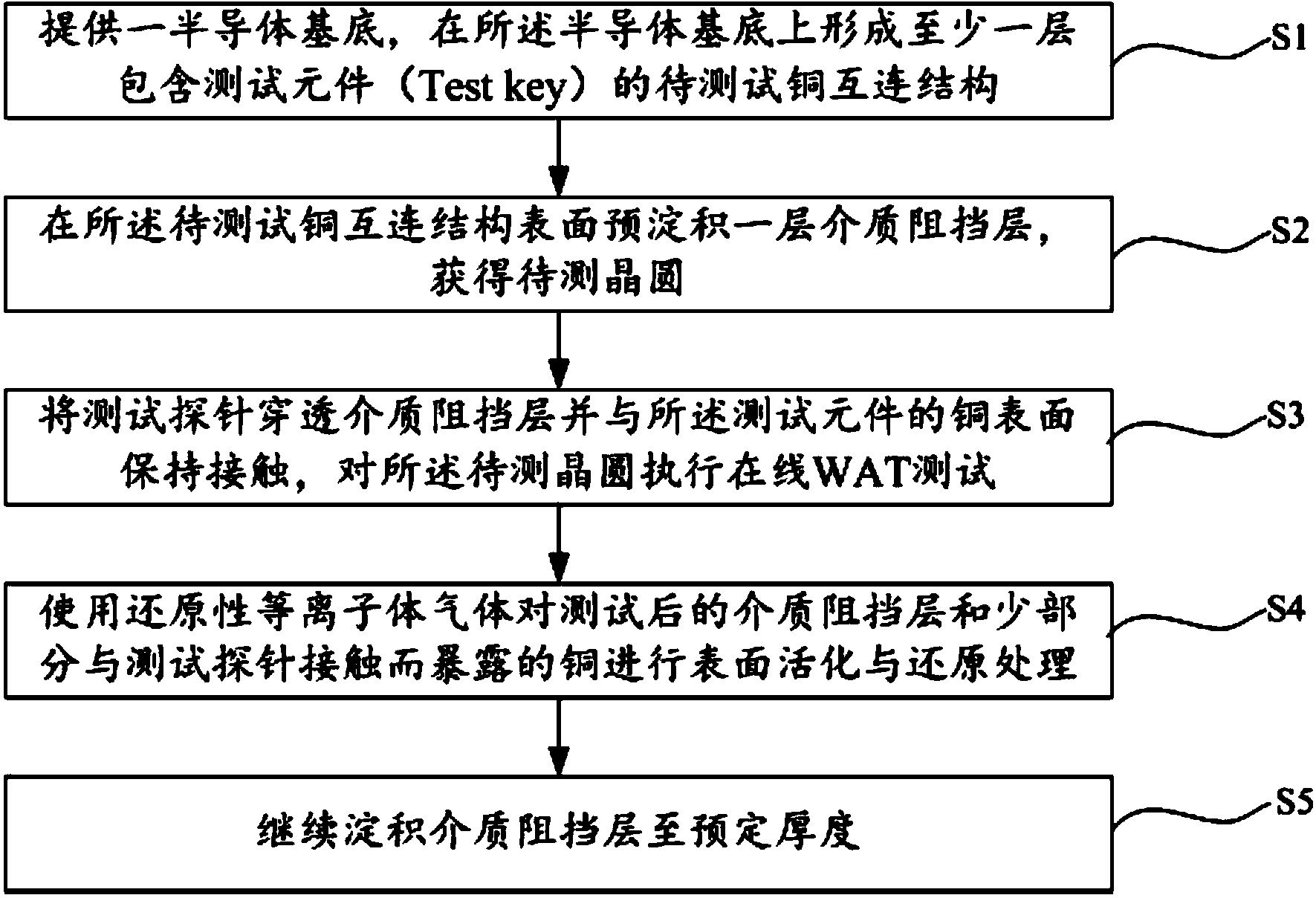

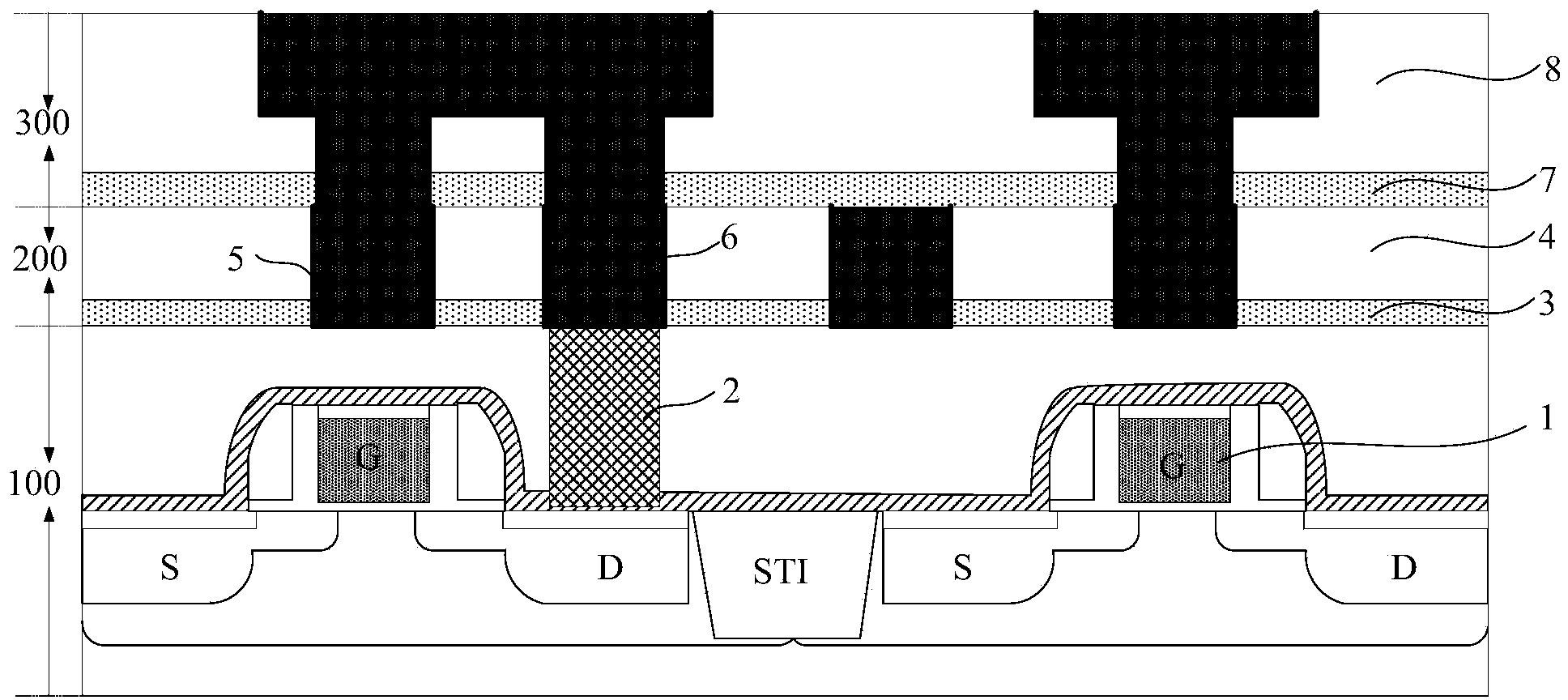

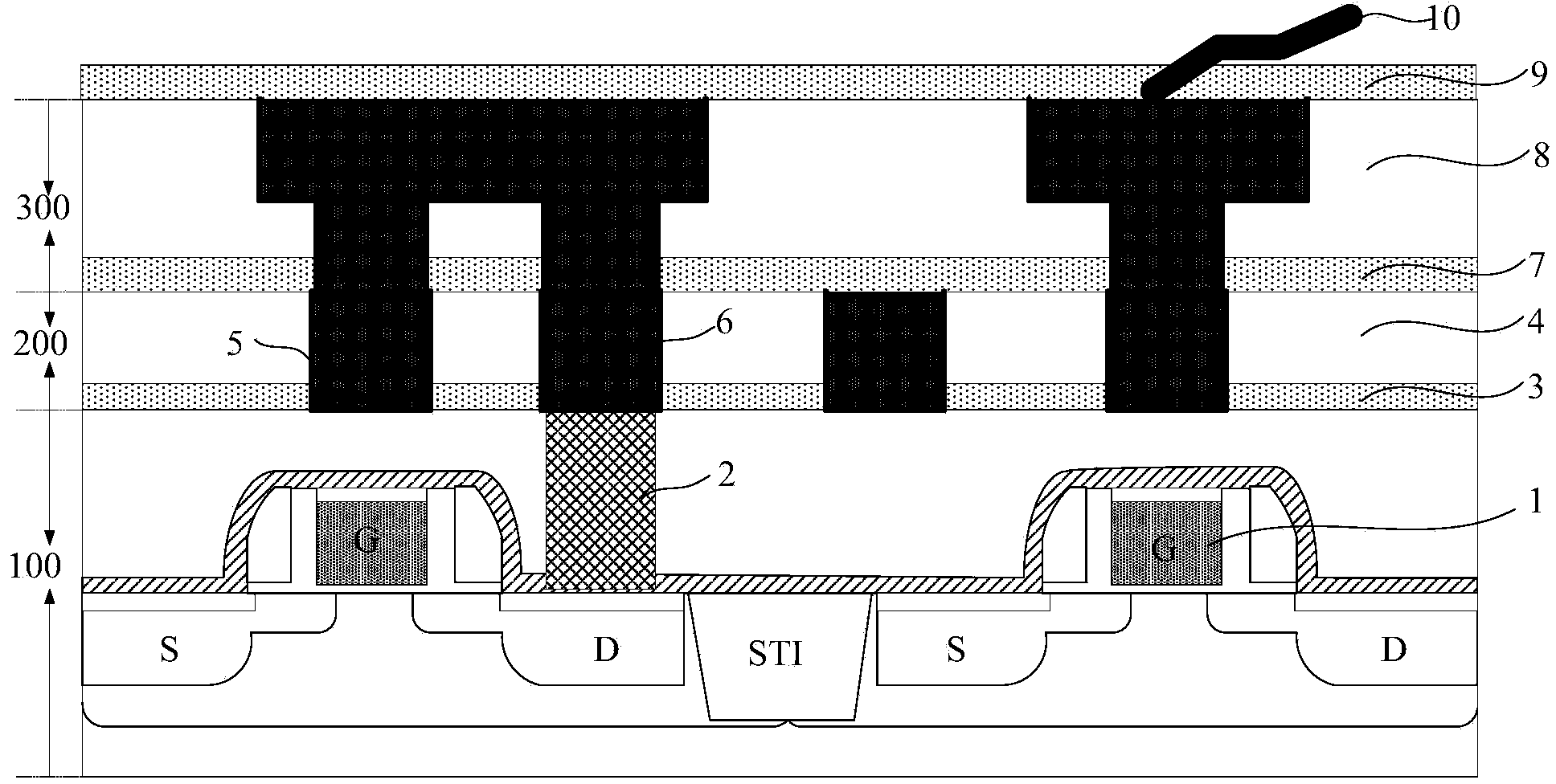

[0035] The core idea of the invention is to disclose a method for reducing the influence of online wafer acceptance test on the reliability of copper interconnection. Among them, firstly, by pre-depositing a thinner dielectric barrier layer on the surface of the copper interconnection structure to be tested, the copper and dielectric material surfaces of the copper interconnection structure to be tested can be tested without affecting the execution of the online WAT test. During the process, it is well isolated and protected; then, by using reducing plasma gas to perform surface activation and reduction treatment on the pre-deposited dielectric barrier layer after the test and a small part of the exposed metal copper in contact with the test probe, it can be effectively removed. The oxides and residual impurities generated on the surface can improve the interface bonding state with the subsequent film; secondly, the dielectric material of the copper interconnection structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com