A kind of preparation method of phosphorus recovery crystal

A technology of phosphorus recovery and crystallization, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of unsuitable calcium-supplying seed crystals, low reactivity, discomfort, etc., to achieve convenient development and application, Reduce the risk of danger and avoid the effect of particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention discloses a preparation method of hydroxywollastonite, and those skilled in the art can learn from the content of this article and appropriately improve the process parameters to realize it. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method and application of the present invention have been described through preferred embodiments, and the relevant personnel can obviously make changes or appropriate changes and combinations to the method and application described herein without departing from the content, spirit and scope of the present invention to realize and Apply the technology of the present invention.

[0045] The raw materials and reagents used in the preparation method of the hydroxynotlite provided by the invention can be purchased from the market.

[0046] The raw materials and reagents of ...

Embodiment 1

[0052] The preparation of embodiment 1 hydroxynotlite

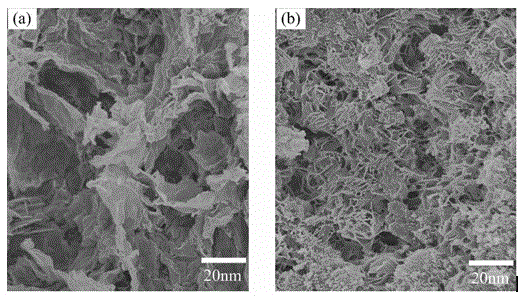

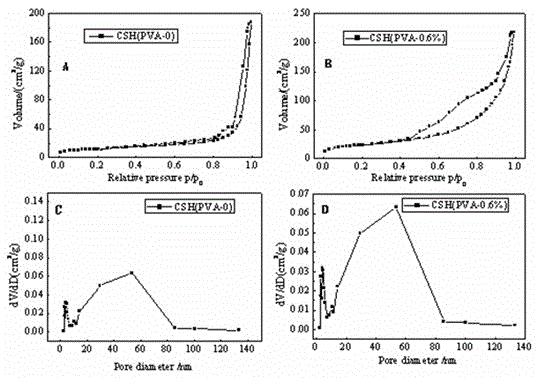

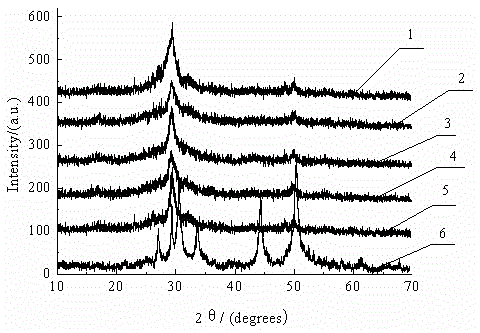

[0053] The raw materials and reagents of the preparation method of the porous hydroxywollastonite proposed by the present invention include: calcareous raw materials, siliceous raw materials, polyvinyl alcohol, potassium hydroxide, ethanol and water. The calcareous raw material is calcium carbide slag, which is calcined at 500°C and kept for 2 hours, then ground and passed through a 120-mesh sieve. The siliceous raw material is a mixture prepared by white carbon black and polyvinyl alcohol (PVA / SiO 2 ). Among them, white carbon black particles are spherical, the diameter of the sphere is about 45 microns, and the size is uniform. 2 The content is above 95%. The water is tap water, distilled water, pure water or ultrapure water. Potassium hydroxide (KOH), ethanol (CH 3 CH 2 OH) is analytically pure. The main instruments include: pressure cooker and ultrasonic oscillator.

[0054] Before preparing the hydroxynotlite...

Embodiment 2

[0058] The preparation of embodiment 2 hydroxynotlite

[0059] Take 40g of white carbon black, 2 L of polyvinyl alcohol (mass concentration: 0.8%, molecular weight: 4000) and 300 L of water, mix it with 300 L of water, shake it under the condition of 100W for 40min, and stir it under the condition of water bath at 80°C to remove excess polyethylene alcohol to obtain 42 g of siliceous raw material. Detected by infrared spectroscopy, at 3458cm -1 , 2916 cm -1 , 1642cm -1 , 1080cm -1 , 1068cm -1 , 792cm -1 and 470cm -1 Appeared absorption peak; Among them, 3458cm -1 The characteristic peak of O-H appears at 1642cm -1 , 1068cm -1 , 792cm -1 and 470cm -1 is the vibration peak of Si-O-Si, 2916 cm -1 and 1080cm -1 Attributed to the vibrational absorption peak of PVA.

[0060] Take 60g of calcium carbide slag, calcinate at 500°C for 1 hour, grind and pass through a 120-mesh sieve to obtain 55g of calcium raw material.

[0061] Get prepared calcareous raw material 55g, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com