Method for purifying fructose oligosaccharide

A technology of fructooligosaccharides and purification methods, which is applied in the direction of oligosaccharides, chemical instruments and methods, sugar derivatives, etc., can solve the problems of low purity of oligosaccharides, and achieve the effects of high purity, improved purity, and high energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

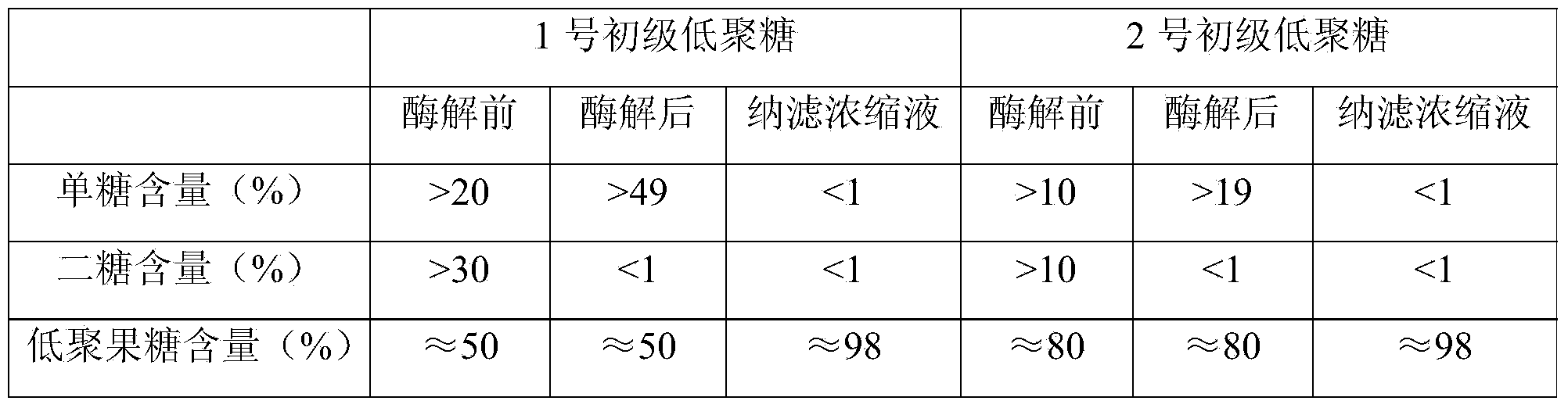

[0022] Get two different grades of primary fructo-oligosaccharide mixture 100mL (No. 1 and No. 2 purity are 50% and 80% respectively, sucrose content is 0.1mol / L) in enzyme reactor, glucosyltransferase is 5U / g , enzyme reaction temperature 30°C, 1mol / L phosphate buffered saline with a pH of 7.0 and 10mL reaction time in 8h, the product after the reaction was treated by a nanofiltration membrane with a molecular weight cut-off of 350Da, before and after enzyme treatment and after nanofiltration treatment, single The contents of sugars, disaccharides and fructooligosaccharides are shown in Table 1.

[0023] Table 1 The effect before and after primary fructo-oligosaccharide enzyme treatment and nanofiltration treatment

[0024]

Embodiment 2

[0026] Take 100mL of primary fructooligosaccharides with a purity of 80% (sucrose content is 0.1mol / L) in an enzyme reactor, glucosyltransferase 10U / g, enzyme reaction temperature 30°C, 1mol / L, pH 7.0 phosphate buffered salt 10mL , and the samples with reaction time between 1 and 20 hours were taken for analysis, and the results are shown in Table 2.

[0027] The impact of table 2 different reaction times on primary fructo-oligosaccharide enzyme enzyme treatment

[0028]

Embodiment 3

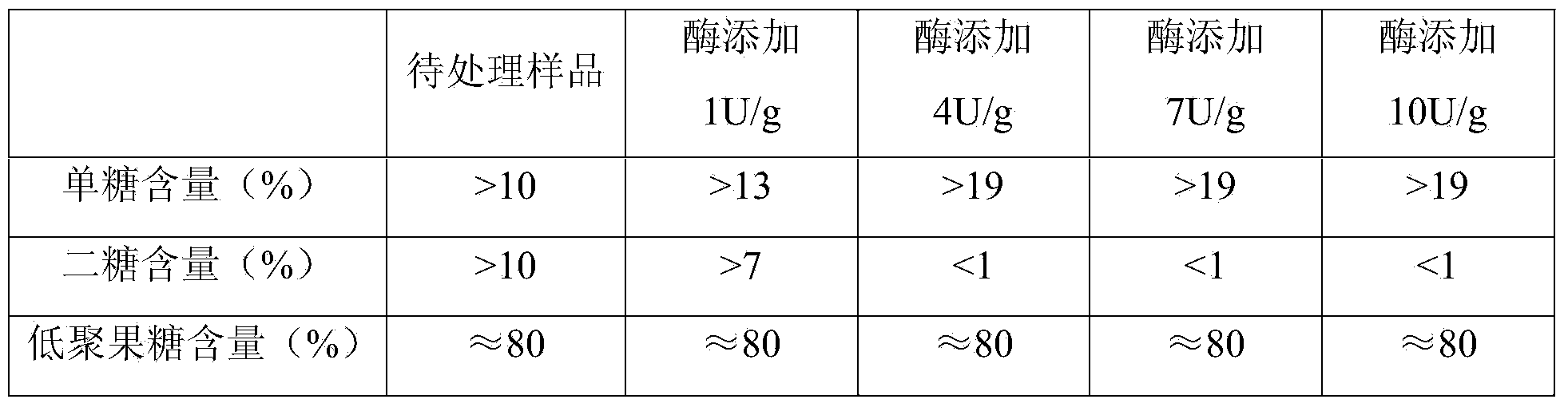

[0030] Take 100mL of primary fructooligosaccharides with a purity of 80% (sucrose content is 0.1mol / L) in an enzyme reactor, glucosyltransferase 1 ~ 10U / g, enzyme reaction temperature 30 ° C, 1mol / L, pH 7.0 phosphate buffer Salt 10mL, reaction time 8h, the results are shown in Table 3.

[0031] Table 3 Effects of different enzyme additions on primary fructooligosaccharide enzyme treatment

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com