Electrolyte adopting propylene carbonate as main solvent

A technology of propylene carbonate and electrolyte, which is applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems that lithium-ion batteries cannot be applied, and the problem of co-embedding of propylene carbonate and graphite-based negative electrodes has not been solved, so as to improve the initial Discharge capacity and effect of improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

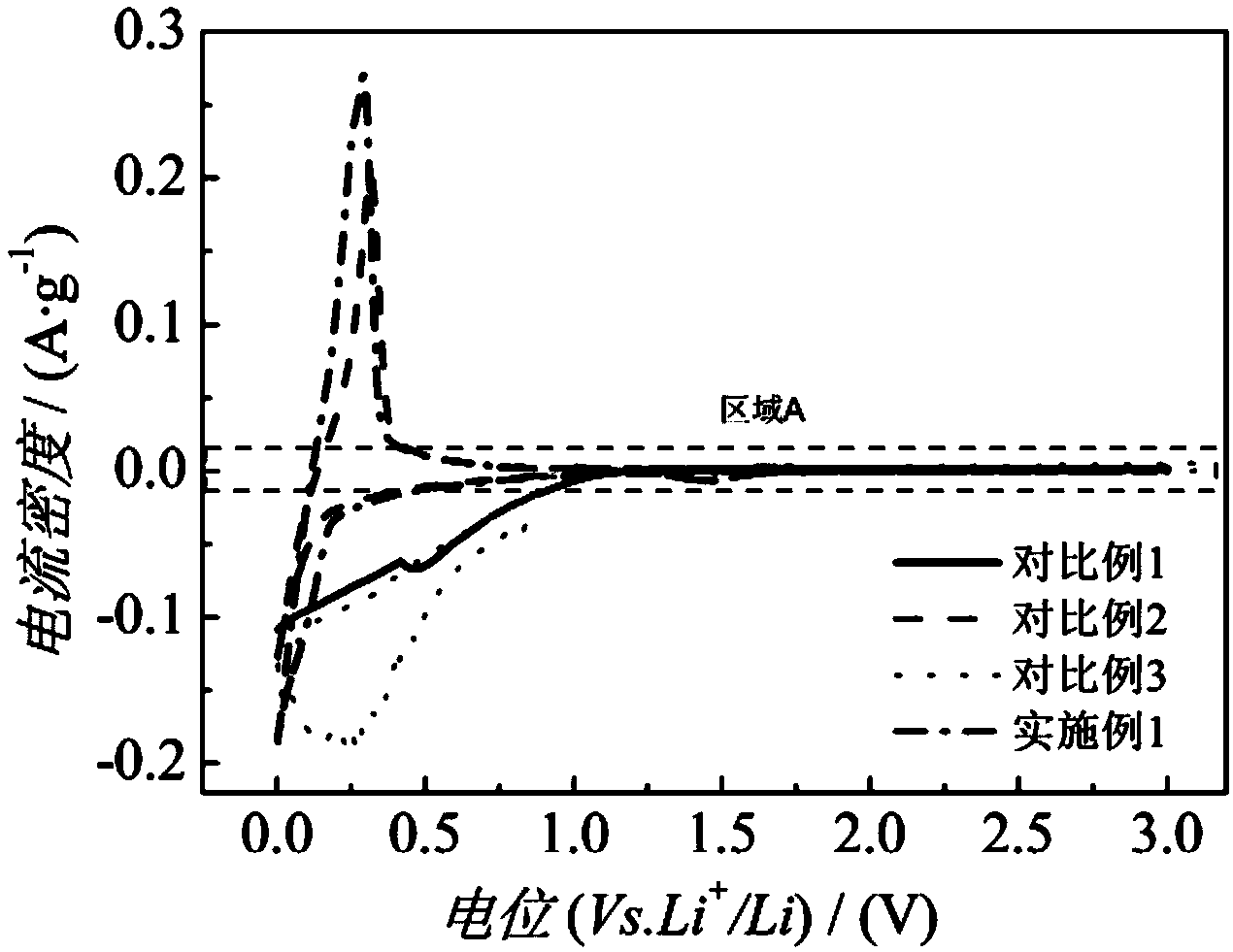

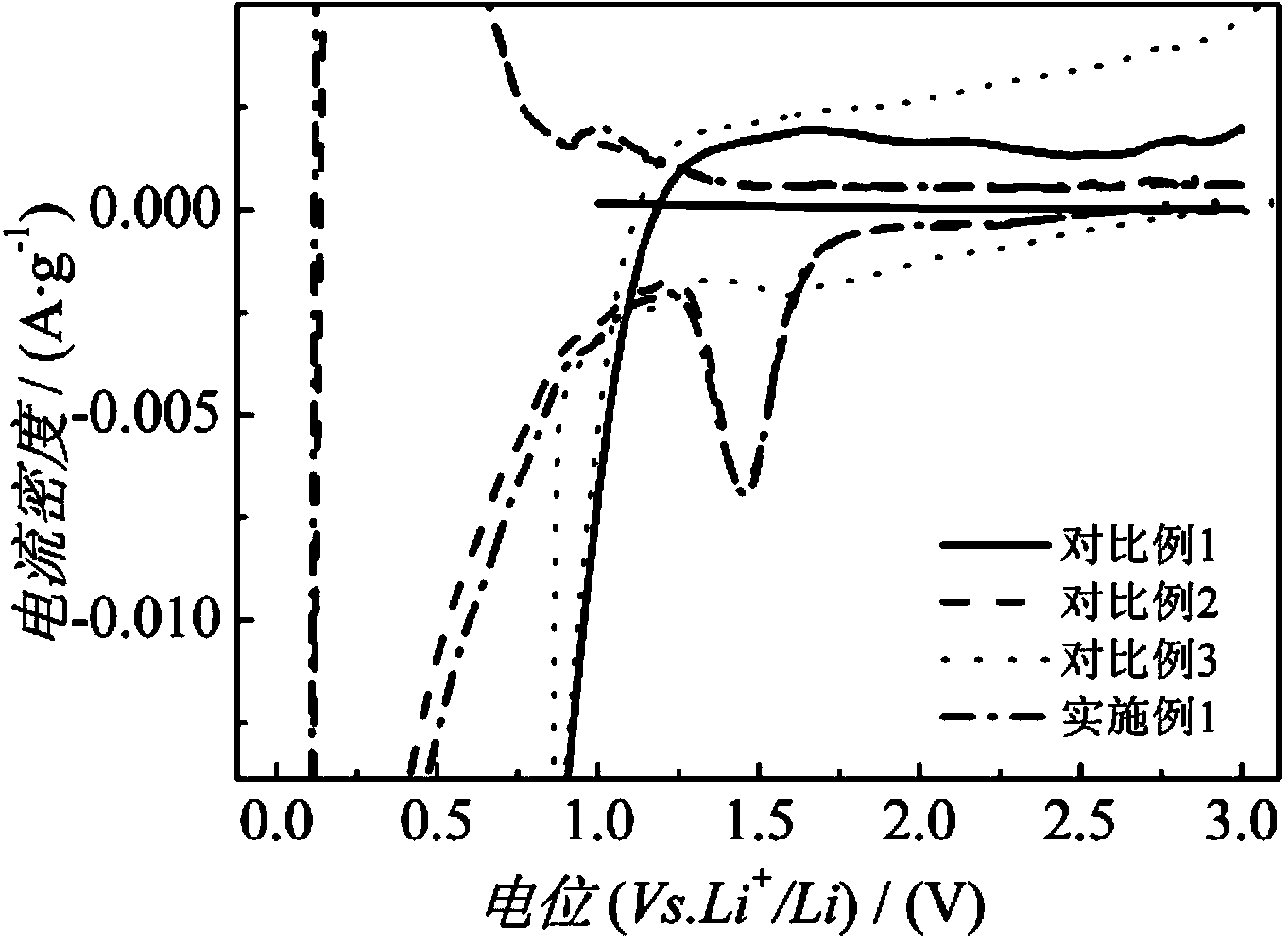

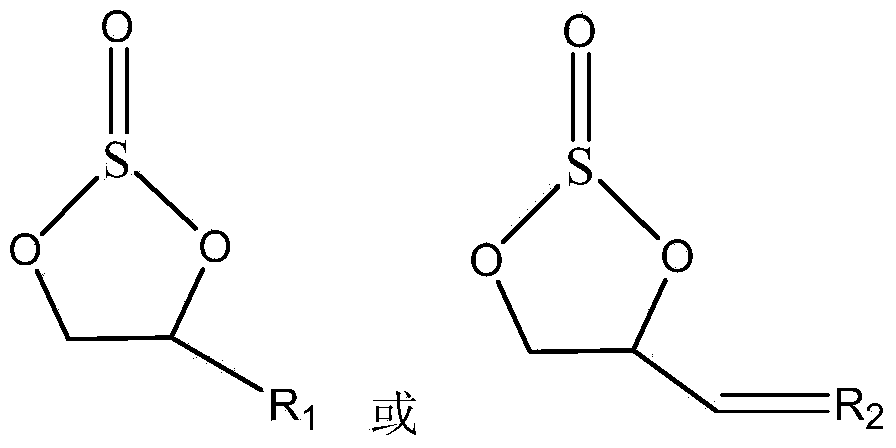

[0027] In an inert atmosphere glove box with moisture less than 5ppm, mix 9g propylene carbonate (PC) and 21g diethylcarbonate (DEC) after molecular sieve dehydration, and then slowly add 4.411g lithium hexafluorophosphate (LiPF 6 ), the temperature of the electrolyte is controlled not to exceed 30°C during the process of adding the lithium salt, and after the lithium salt is completely dissolved, add 1.032g of vinyl sulfite (VES) and 0.688g of vinylene carbonate (VC), and shake well to obtain electrolyte.

[0028] The mass ratio of each component in the electrolyte is as follows: Lithium salt LiPF 6 12% for PC, 25% for PC, 58% for DEC, 2% for additive VC, and 3% for additive vinyl vinyl sulfite (VES).

Embodiment 2

[0030] The mass ratio of each component in the electrolyte is as follows: Lithium salt LiPF 6 12% for PC, 25% for DEC, 60% for DEC, 2% for additive VC, and 1% for additive vinyl vinyl sulfite (VES).

Embodiment 3

[0032] The mass ratio of each component in the electrolyte is as follows: Lithium salt LiPF 6 10% for PC, 60% for DEC, 15% for DEC, 5% for additive VC, and 10% for additive vinyl vinyl sulfite (VES).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com