Quasi-solid electrolyte PVA-zinc-air battery

An air battery, PVA-KOH-H2O technology, applied in electrical components, battery electrodes, fuel cell-type half-cells and primary battery-type half-cells, etc., can solve the problem of reducing battery performance, direct oxidation of zinc electrodes, and battery leakage. Liquid and other problems, to prolong the service life of charging and discharging, solve the formation of zinc dendrites, and prevent the effect of battery leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: 1) Weigh a certain amount of polyvinyl alcohol particles, mix them with water at 0.5:32, heat and stir in a water bath, the temperature of the water bath is 90°C, stir for 60 minutes, the transparent polyvinyl alcohol particles gradually disappear, and the water gradually becomes Viscous; 2) After the transparent particles are completely dissolved, continue to heat in a water bath for 10 minutes to evaporate excess water, so that the water content of PVA is 60%-70%; 3) Add 40%-50% of pre-prepared 5 ~6mol / L of KOH; obtain PVA solution; 4) place the PVA solution of step 3) at room temperature and allow it to cool naturally, the PVA solution gradually becomes a frozen solid, and when it does not completely become a frozen solid, put It drips into the battery case for final subsequent encapsulation.

Embodiment 2

[0043] Example 2: Same as the above steps, the difference is: 1) The mixing ratio of polyvinyl alcohol particles and water is: 1:40, the temperature of the water bath is 88 ° C, and stirred for 70 minutes; 2) After the particles are dissolved, continue heating in the water bath 20 minutes; 3) Add 40% of pre-prepared 7 mol / L KOH dropwise.

Embodiment 3

[0044] Example 3: The steps are the same as in Example 1, the difference is: 1) The mixing ratio of polyvinyl alcohol particles and water is: 1:30, the temperature of the water bath is 95°C, and stirred for 50 minutes; 2) After the particles are dissolved, continue Heat in a water bath for 20 minutes; 3) Add 50% of pre-prepared 7 mol / L KOH dropwise.

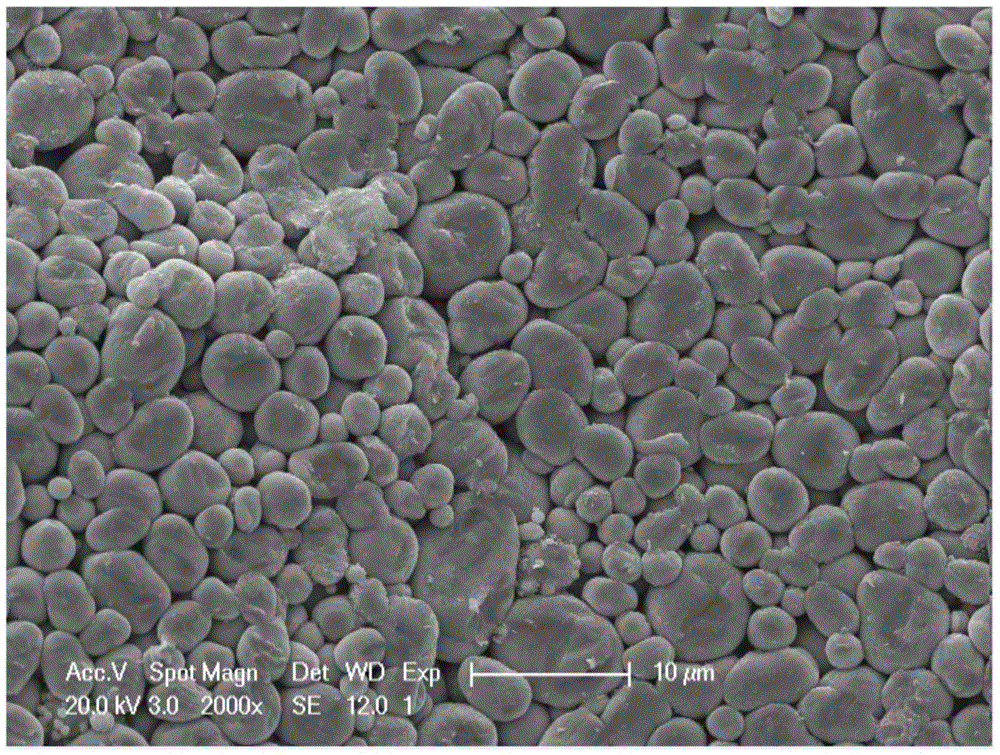

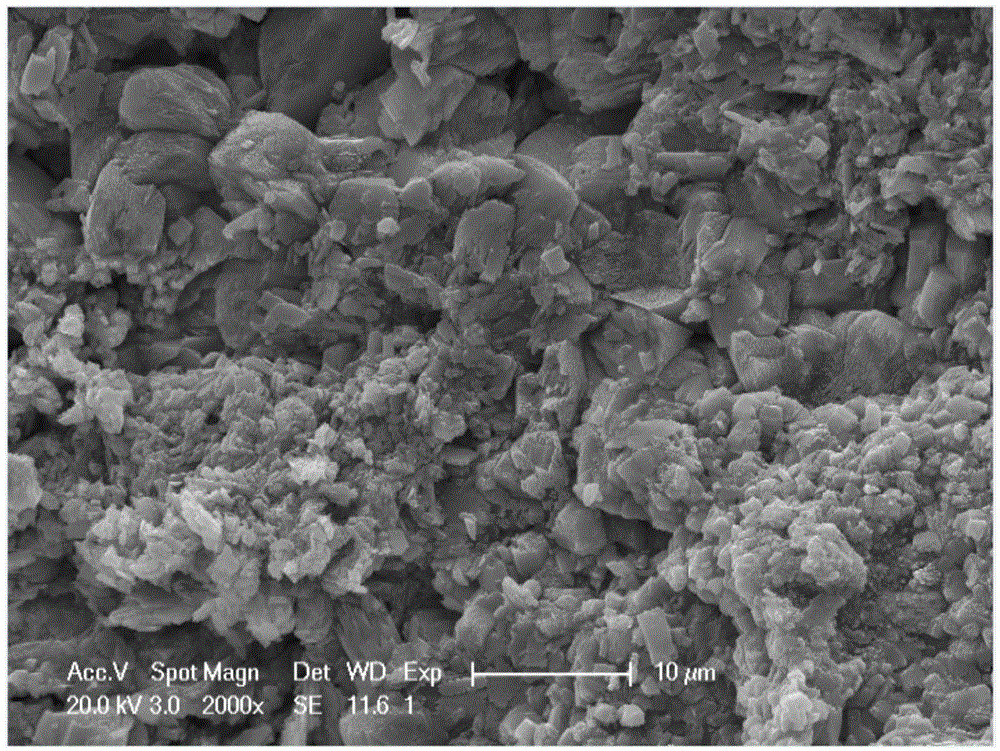

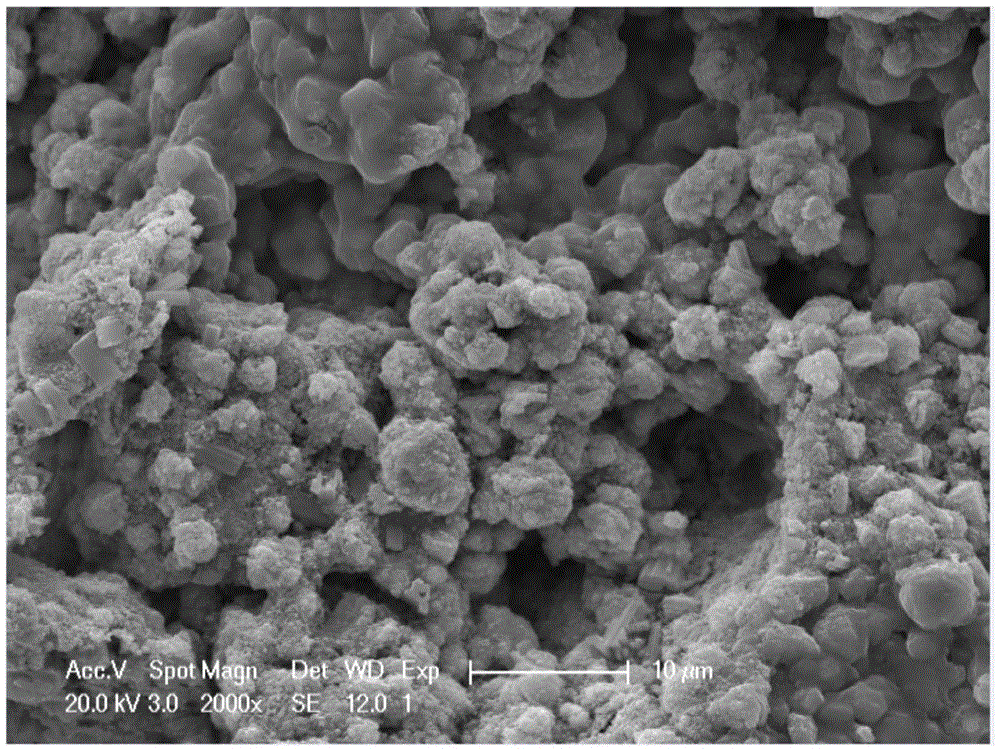

[0045] Preparation of zinc electrode:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com