Novel crude fiber healthcare moon cake and production method thereof

A technology of crude fiber and moon cakes, which is applied in the field of new crude fiber health-care moon cakes and its production, can solve the problems of easy induction of cardiovascular and cerebrovascular diseases, high preservative content, lack of nutrition and health care, etc., achieve good market prospects and promotion value, easy to use Absorption and immunity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

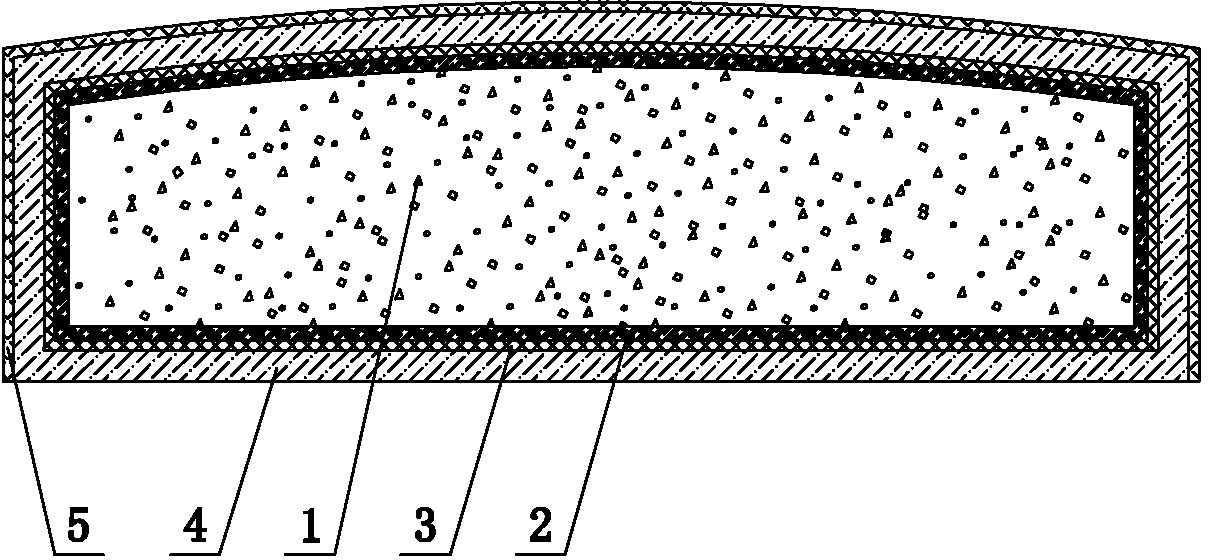

Image

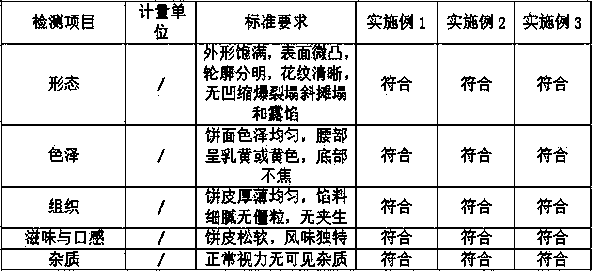

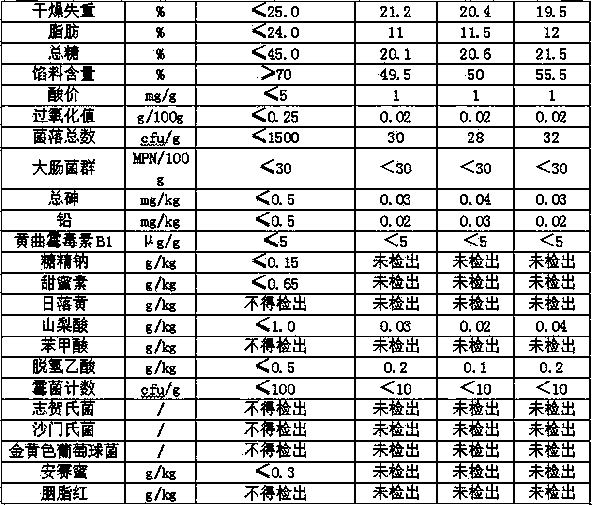

Examples

Embodiment 1

[0029] 1. Put 80 parts of rice bran, 8 parts of corn flour and 22 parts of water into a solid fermentation reaction tank according to the weight ratio, cook and sterilize at 95°C for 2 minutes, cool to 22°C and inoculate the tank with 0.6 0.02 parts of Bacillus subtilis, 0.001 parts of Lactobacillus, 0.2 parts of fresh yeast, after stirring, ferment at pH 4.5 and 22°C for 6 hours, filter the obtained reactant A, and mix with 80 parts of high-gluten flour, butter 6 parts and 0.3 parts of soda are mixed, kneaded into a skin and folded several times, then kneaded into dough B for later use;

[0030] 2. Mix 30 parts of denatured flour, 0.4 parts of seaweed gel, and 10 parts of egg white to make batter C for later use;

[0031] 3. Dissolve 10 parts of mushroom polysaccharide in 22 parts of water to make a mushroom polysaccharide solution, then slowly mix with 100 parts of low-gluten flour, 4 parts of lotus leaf powder, 8 parts of camellia oil, and 0.3 parts of soda to form a dough,...

Embodiment 2

[0036] 1. Put 85 parts of rice bran, 9 parts of corn flour and 26 parts of water into the solid fermentation reaction tank according to the weight ratio, cook and sterilize at 100°C for 1.5 minutes, cool to 26°C and inoculate the tank with 0.8% cellulase 0.03 parts of Bacillus subtilis, 0.0015 parts of Lactobacillus, 0.25 parts of fresh yeast, after stirring, ferment at pH 5.3 and 27°C for 7 hours, filter the obtained reactant A, and mix with 90 parts of high-gluten flour, butter After mixing 7 parts and 0.4 parts of soda, knead it into a skin and fold it several times, then knead it into a dough B for later use;

[0037] 2. Mix 40 parts of denatured flour, 0.6 parts of seaweed gel, and 13 parts of egg white to make batter C for later use;

[0038] 3. Dissolve 12.5 parts of mushroom polysaccharide in 26 parts of water to make a mushroom polysaccharide solution, then slowly mix with 100 parts of low-gluten flour, 6 parts of lotus leaf powder, 10 parts of camellia oil, and 0.4 pa...

Embodiment 3

[0043] 1. Put 90 parts of rice bran, 10 parts of corn flour and 30 parts of water into a solid fermentation reaction tank according to the weight ratio, cook and sterilize at 105°C for 1 minute, cool to 30°C and inoculate cellulase 1 into the tank 0.04 parts of Bacillus subtilis, 0.002 parts of Lactobacillus, 0.3 parts of fresh yeast, after stirring, ferment at pH 6 and 32°C for 8 hours, filter the obtained reactant A, and mix with 100 parts of high-gluten flour, butter 8 parts and 0.5 parts of soda are mixed, kneaded into skin and folded several times, then kneaded into dough B for later use;

[0044] 2. Mix 50 parts of denatured flour, 0.8 parts of seaweed gel, and 16 parts of egg white to make batter C for later use;

[0045] 3. Dissolve 15 parts of mushroom polysaccharide in 30 parts of water to make a mushroom polysaccharide solution, then slowly mix with 100 parts of low-gluten flour, 8 parts of lotus leaf powder, 12 parts of camellia oil, and 0.5 parts of soda to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com