Three-layer composite structure polypropylene microporous membrane and preparation method thereof

A technology of polypropylene microporous membrane and three-layer structure, which is applied in the field of microporous membranes, can solve the problems of inability to guarantee battery safety and poor safety, and achieve the prevention of abnormal battery temperature rise, low closed cell temperature, and low thermal shrinkage rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

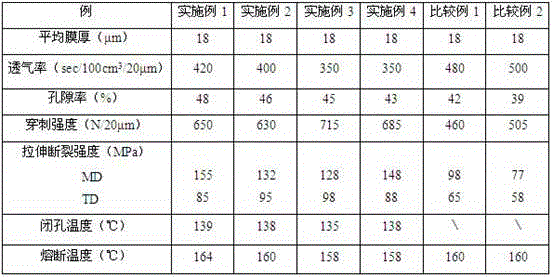

Examples

Embodiment 1

[0023] 1) 0.1% by weight of terephthalic acid, 0.1% by weight of barium oxide and 99.8% by weight of homopolypropylene were mixed and extruded to obtain β-crystal homopolypropylene, and its β-crystal content was measured to be 82%, the melt index is 8, the crystallinity is 62%, and the melting point is 165°C.

[0024] 2) 0.1% by weight of terephthalic acid, 0.1% by weight of barium oxide and 99.8% by weight of ethylene-propylene copolymerized polypropylene were mixed and extruded to obtain β-crystal copolymerized polypropylene, and the content of β-crystal form was measured to be 79%, the melt index is 15, the crystallinity is 51%, and the melting point is 141°C.

[0025] 3) The above-mentioned β-crystal homopolypropylene is used as the raw material of the surface layer A and surface layer C, and the above-mentioned β-crystal copolymerized polypropylene is used as the raw material of the core layer B, which are respectively melted and kneaded at 220°C and then compounded by th...

Embodiment 2

[0029] 1) Mix and extrude 0.5% by weight of azelaic acid, 1% by weight of calcium stearate and 98.5% by weight of homopolypropylene to obtain β-crystal homopolypropylene, and measure its β-crystal content It is 89%, the melt index is 7, the crystallinity is 60%, and the melting point is 162°C.

[0030] 2) Mix and extrude 0.5% by weight of azelaic acid, 1% by weight of calcium stearate and 98.5% by weight of ethylene-propylene-butylene ternary copolymerized polypropylene to obtain β-crystalline copolymerized polypropylene, and measure its β-crystalline The molar content is 78%, the melt index is 16, the crystallinity is 44%, and the melting point is 140°C.

[0031] 3) The above-mentioned β-crystal copolymerized polypropylene is used as the raw material of the surface layer A and the surface layer C, and the above-mentioned β-crystal homopolypropylene is used as the raw material of the core layer B, which are respectively melted and kneaded at 210°C and then compounded by three ...

Embodiment 3

[0035] 1) 1% by weight of adipic acid, 2% by weight of calcium carbonate and 97% by weight of homopolypropylene were mixed and extruded to obtain β-crystal homopolypropylene I, and its β-crystal content was measured to be 88%, the melt index is 6.5, the crystallinity is 58%, and the melting point is 163°C. 1.5% by weight of phthalimide, 3% by weight of magnesium oxide and 95.5% by weight of homopolypropylene were mixed and extruded to obtain β-crystal homopolypropylene II, and its β-crystal content was measured It is 85%, the melt index is 7.2, the crystallinity is 60%, and the melting point is 160°C.

[0036] 2) Mix and extrude 1% by weight of adipic acid, 2% by weight of calcium carbonate and 97% by weight of ethylene-propylene-butylene ternary copolymerized polypropylene to obtain β-crystal form copolymerized polypropylene, and measure its β-crystal form content It is 80%, the melt index is 18, the crystallinity is 43%, and the melting point is 138°C.

[0037]3) The above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com