Preparation method of citric acid grafted chitosan hydrogel

A technology of citric acid and chitosan, which is applied in the field of preparation of citric acid-grafted chitosan hydrogel, can solve the problems of increasing dispersion, affecting the strength of chitosan materials, and decreasing molecular weight, etc., achieving high mechanical strength, Considering the effect of biocompatibility and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

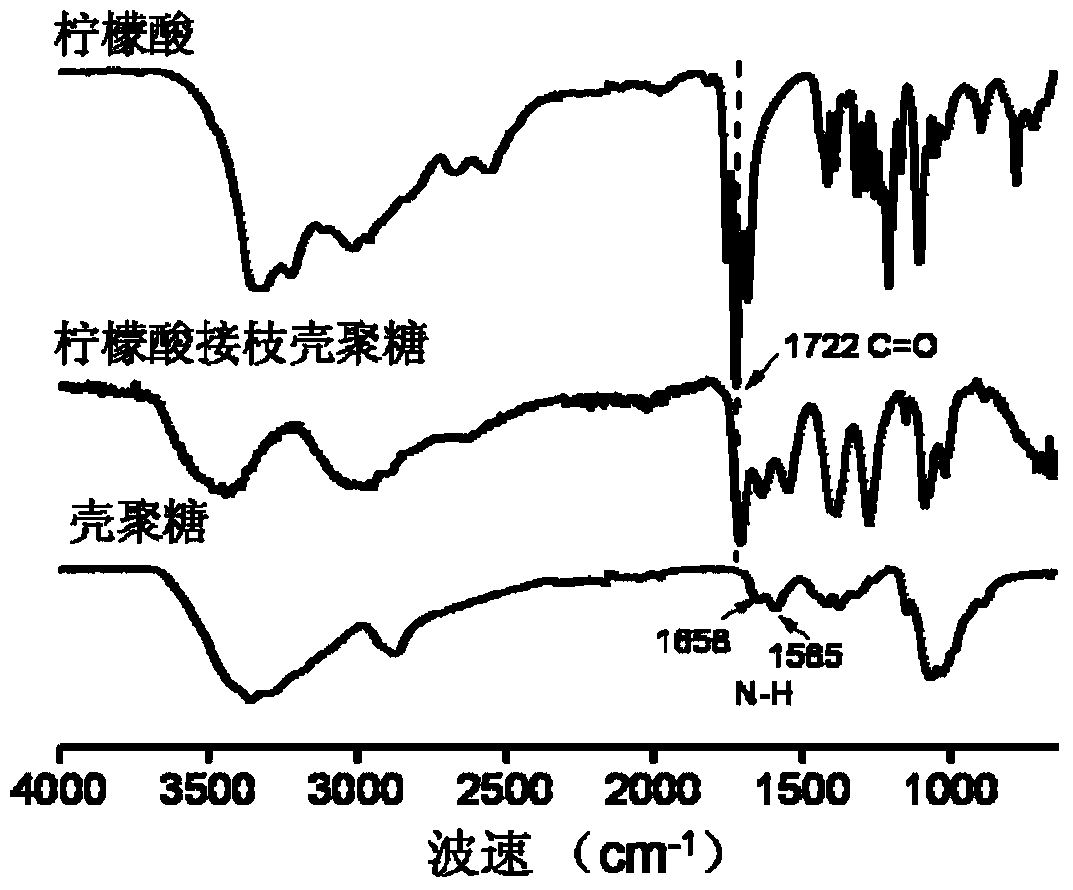

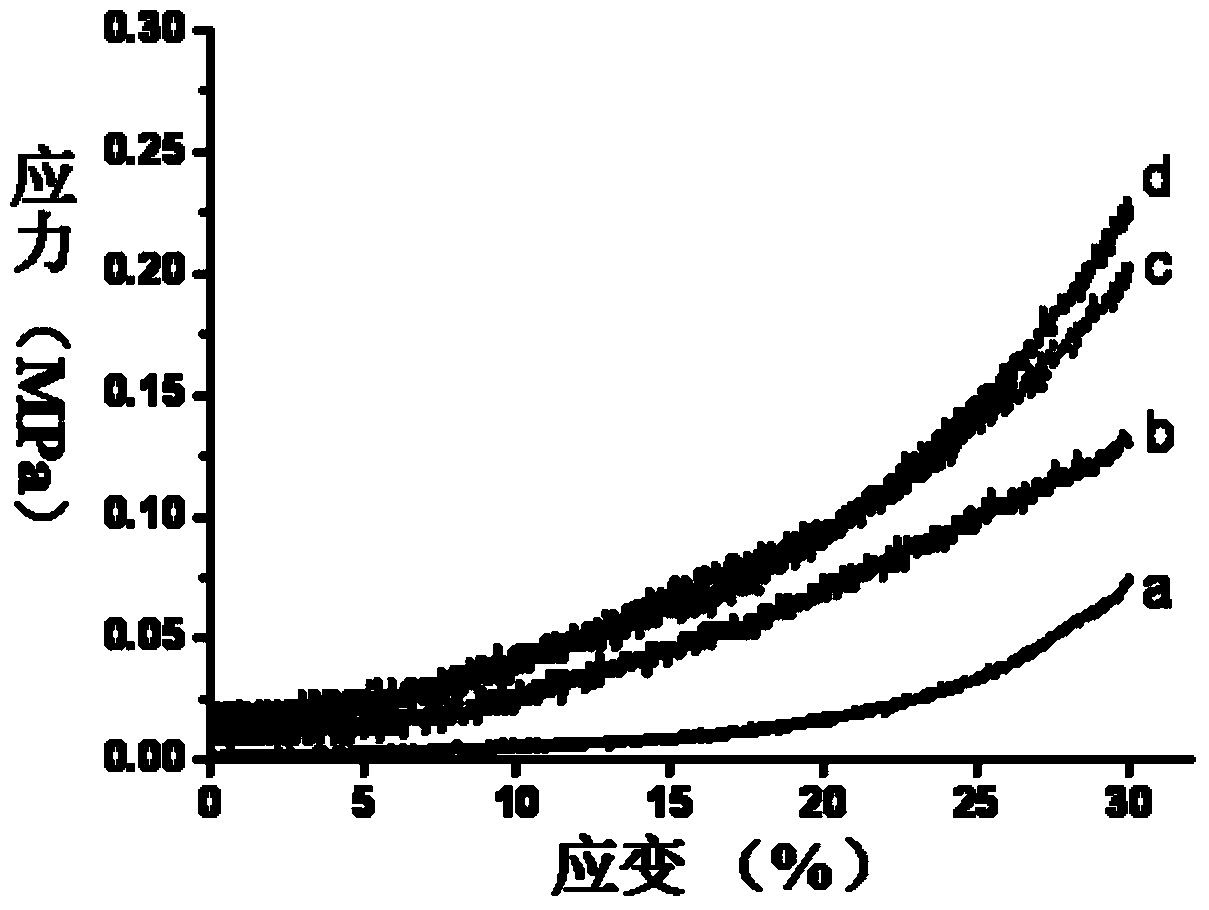

[0026] At room temperature, weigh 0.1g chitosan and 0.2g citric acid and disperse in 10g ethanol, then react under magnetic stirring at room temperature 25°C for 4h, centrifuge the product after the reaction, then dissolve it in distilled water and add absolute ethanol Settling and washing 3 times until the pH of the solution=4 is constant, and the precipitate is dried at a constant temperature at 55° C. to constant weight to obtain citric acid grafted chitosan (such as figure 1 , the carbonyl peak in the amide bond appeared in the infrared spectrum of citric acid grafted chitosan, indicating that the chemical grafting was successful). Weigh 0.1g of citric acid-grafted chitosan and dissolve it in 10g of distilled water, take a small amount of the solution into a mold, and then freeze it in a -20°C refrigerator for 12h to form a jelly. The jelly was melted with 0.5M NaOH solution at room temperature for 4 h, and then the gel was washed with distilled water until neutral to obt...

Embodiment 2

[0028] At room temperature, weigh 0.1g of chitosan and 0.2g of citric acid and disperse them in 10g of ethanol, then react at 37°C for 4h under magnetic stirring. Analysis and washing were performed for 3 times until the pH = 4, and the precipitate was dried at a constant temperature at 55° C. to a constant weight to obtain citric acid grafted chitosan. Weigh 0.2g of citric acid-grafted chitosan and dissolve it in 10g of distilled water, take a small amount of the solution into a mold, and then freeze it in a -20°C refrigerator for 12h to form a jelly. The jelly was melted with 0.5M NaOH solution at room temperature for 4 h, and then the gel was washed with distilled water until neutral to obtain a high-strength citric acid grafted chitosan hydrogel ( figure 2 b). When the compression ratio is 30%, its compressive strength is 0.13MPa ( image 3 b).

Embodiment 3

[0030] At room temperature, weigh 0.1g of chitosan and 0.2g of citric acid and disperse them in 10g of ethanol, then react at 50°C for 4h under magnetic stirring. After analysis and washing for 3 times until the solution pH=4, the precipitate was dried at a constant temperature at 55° C. to a constant weight to obtain citric acid grafted chitosan. Weigh 0.3g of citric acid-grafted chitosan and dissolve it in 10g of distilled water, take a small amount of the solution into a mold, and then freeze it in a -20°C refrigerator for 12h to form a jelly. The jelly was melted with 0.5M NaOH solution at room temperature for 4 h, and then the gel was washed with distilled water until neutral to obtain a high-strength citric acid grafted chitosan hydrogel ( figure 2 c). When the compression ratio is 30%, its compressive strength is 0.20MPa ( image 3 c).

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com