Red phosphor for LED, and preparation method thereof

A technology of red phosphor and phosphor, which is applied in the field of LED red phosphor and its preparation, alkaline earth metal niobate red phosphor and its preparation, can solve the problem of low color rendering index of white LED, poor stability of phosphor, The luminous efficiency is not high, and the physical and chemical properties are stable, the luminous performance is excellent, and the temperature stability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (Ca 098 K 001 PR 001 ) 2 Nb 2 o 7 Sample preparation:

[0037] (1) Weigh raw material CaCO 3 7.8392g,K 2 CO 3 0.055g, Pr 6 o 11 0.1361g, Nb 2 o 5 10.6277g, the above raw materials are all analytically pure, put into an agate mortar and add 30g of absolute ethanol to grind for 2 hours, then dry in an oven at 60°C;

[0038] (2) Place the dried mixed powder in an alumina crucible and pre-fire it at 900°C for 4 hours in an air atmosphere;

[0039] (3) Calcining the ground calcined powder at 1400° C. for 4 hours in an air atmosphere;

[0040] (4) The cooled product is physically crushed, ground, washed with water to remove impurities, and dried to obtain a chemical composition of (Ca 098 K 001 PR 001 ) 2 Nb 2 o 7 LEDs use red phosphor.

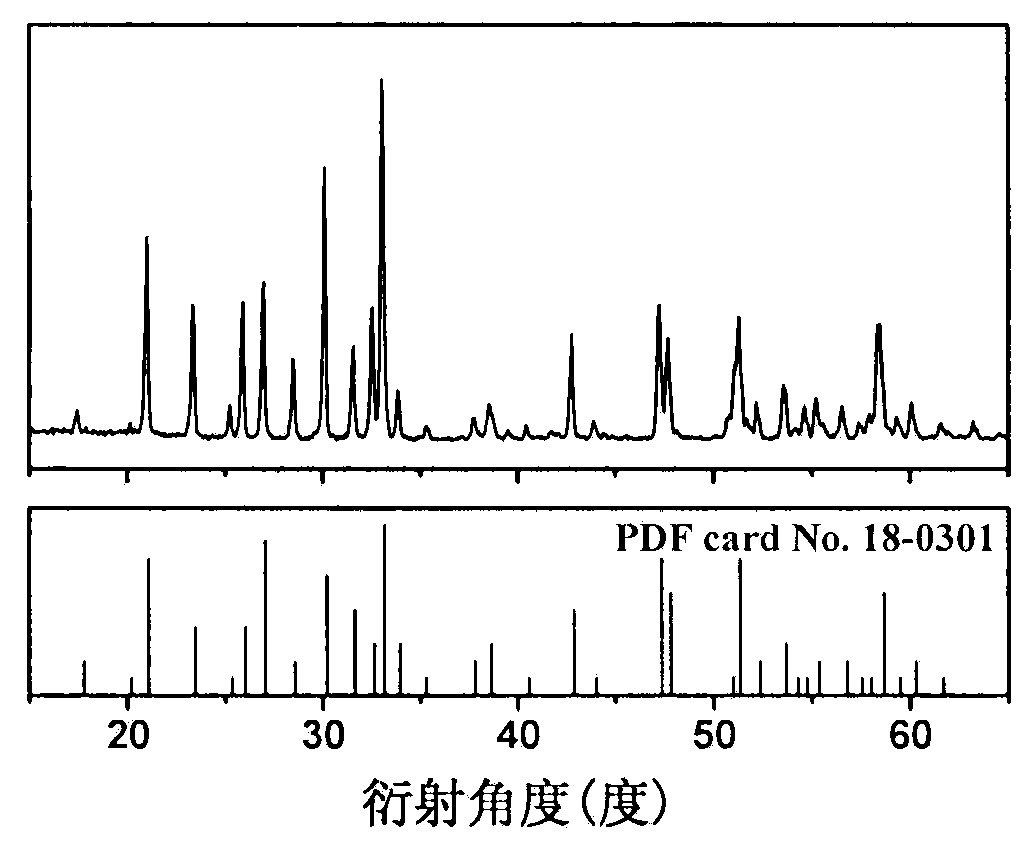

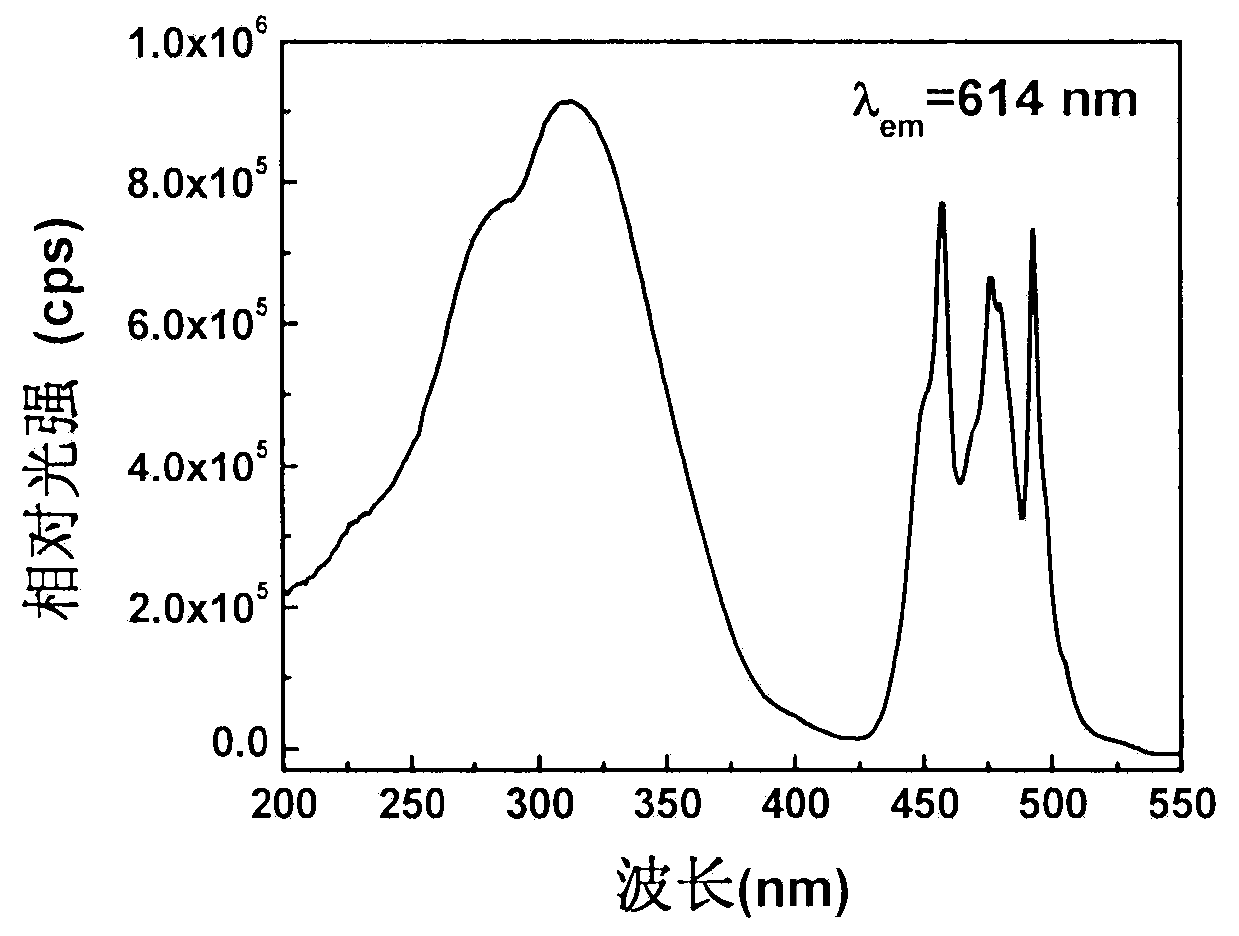

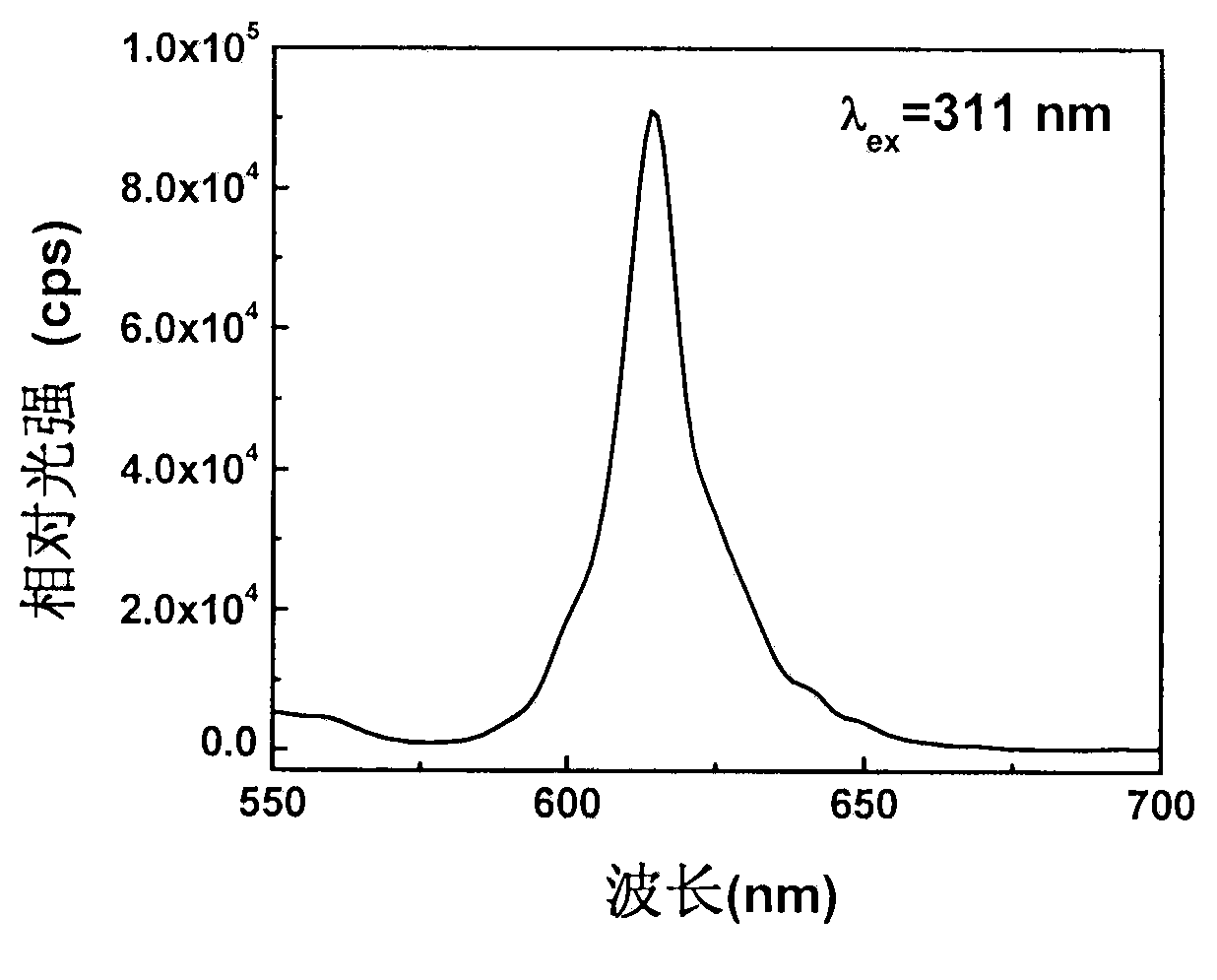

[0041] The appearance of the red phosphor powder prepared by this embodiment is white, and the X-ray powder diffraction (XRD) test shows that as figure 1 As shown, the diffraction peak data of the obtained samples are rela...

Embodiment 2

[0043] (Ca 097 Na 0015 PR 0015 ) 2 Nb 2 o 7 Sample preparation:

[0044] (1) Weigh raw material CaCO 3 7.7592g, Na 2 CO 3 0.0633g, Pr 6 o 11 0.2041g, Nb 2 o 5 10.6277g, the above raw materials are all analytically pure, put into an agate mortar and add 25g of absolute ethanol to grind for 1.5 hours, then dry in an oven at 70°C;

[0045] (2) Place the dried mixed powder in an alumina crucible and pre-fire it at 850°C for 4 hours in an air atmosphere;

[0046] (3) Calcining the ground calcined powder at 1350° C. for 6 hours in an air atmosphere;

[0047] (4) The cooled product is physically crushed, ground, washed with water to remove impurities, and dried to obtain a chemical composition of (Ca 097 Na 0015 PR 0015 ) 2 Nb 2 o 7 LEDs use red phosphor.

[0048] The appearance of the red fluorescent powder for LEDs prepared in this example is white, and the XRD spectrum result is basically consistent with that of Example 1. The excitation peak position, emission...

Embodiment 3

[0050] (Ca 093 8r 005 K 001 PR 001 ) 2 Nb 2 o 7 Sample preparation:

[0051] (1) Weigh raw material CaCO 3 7.4392g, SrCO 3 0.5899g, K 2 CO 3 0.055g, Pr 6 o 11 0.1361g, Nb 2 o 5 10.6277g, the above raw materials are analytically pure, put into an agate mortar, add 35g of deionized water and grind for 2.5 hours, then dry in an oven at 80°C;

[0052] (2) Place the dried mixed powder in an alumina crucible and pre-burn it at 850°C for 5 hours in an air atmosphere;

[0053] (3) calcining the ground calcined powder at 1350° C. for 8 hours in an oxygen atmosphere;

[0054] (4) The cooled product is physically crushed, ground, washed with water to remove impurities, and dried to obtain a chemical composition of (Ca 093 Sr 005 K 001 PR 001 ) 2 Nb 2 o 7 LEDs use red phosphor.

[0055] The appearance of the red fluorescent powder for LEDs prepared in this example is white, and the XRD spectrum result is basically consistent with that of Example 1. The excitation pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com