Compound corrosion inhibitor applicable to sewage medium and preparation method thereof

A corrosion inhibitor and compounding technology, which is applied in the field of compound corrosion inhibitor and its preparation, can solve the problems of poor biodegradability, environmental pollution, and no evaluation of corrosion inhibition effect, and achieve excellent corrosion inhibition effect , good water solubility, excellent corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present invention proposes a method for preparing a composite corrosion inhibitor suitable for sewage corrosive media, which specifically includes the following steps:

[0034] Step 1: Synthesis of linseed oil amide.

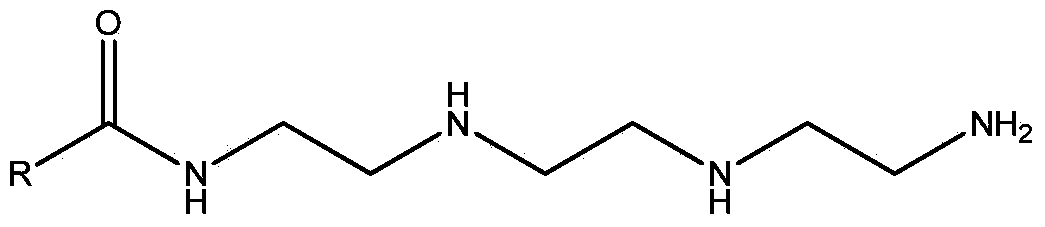

[0035] In a 250ml four-necked bottle, linseed oil and triethylenetetramine are dissolved in xylene solvent at a molar ratio of 1:1–1:3, and the volume of xylene added to each mole of linseed oil is 20–40ml, and heated slowly under nitrogen protection To 100-150°C, add concentrated sulfuric acid catalyst at the same time, react at 100-150°C for 3-4 hours, the amount of the catalyst added is 0.1-0.5ml per mole of linseed oil, after the reaction, distill out distillate toluene. Cool down to room temperature.

[0036] A light yellow viscous liquid was obtained, soluble in water, with a purity of over 90%.

[0037] Among them, the raw material of linseed oil was purchased from Zhangjiakou Xinte Vegetable Oil Co., Ltd., and its main components are shown ...

Embodiment 2

[0049] The main difference between this embodiment and embodiment 1 lies in step 2, specifically:

[0050] Linseed oil amide, phosphonoglycolic acid, zinc sulfate heptahydrate, polyaspartic acid and isopropanol are mixed according to their mass fractions of 30%, 40%, 10%, 10% and 10%, respectively, to obtain Composite corrosion inhibitor.

[0051]The compound corrosion inhibitor obtained is added to the sewage solution according to the specific gravity of 0.02g of the compound corrosion inhibitor per 100g of sewage medium, and placed in the sewage solution with and without the compound corrosion inhibitor The carbon steel test piece was subjected to weight loss test according to the test method of China National Petroleum Corporation's enterprise standard Q / SY TZ0178-2007, soaked at 50°C for 4 days, and the weight loss results are shown in Table 2. After adding the corrosion inhibitor, the weight loss of carbon steel is significantly reduced, and the surface of carbon steel i...

Embodiment 3

[0055] The main difference between this embodiment and embodiment 1 lies in step 2, specifically:

[0056] Mix linseed oil amide, phosphonoglycolic acid, zinc sulfate heptahydrate, polyaspartic acid and isopropanol according to their mass fractions of 50%, 20%, 5%, 15% and 10%, respectively, to obtain Composite corrosion inhibitor.

[0057] The compound corrosion inhibitor obtained is added to the sewage solution according to the specific gravity of 0.1g of the compound corrosion inhibitor per 100g of sewage medium, and placed in the sewage solution with and without the compound corrosion inhibitor The carbon steel test piece was subjected to weight loss test according to the test method of China National Petroleum Corporation's enterprise standard Q / SY TZ0178-2007, soaked at 50°C for 4 days, and the weight loss results are shown in Table 3. After adding the corrosion inhibitor, the weight loss of carbon steel is significantly reduced, and the surface of carbon steel is very ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com