High temperature safety lithium ion battery non-aqueous electrolyte

A non-aqueous electrolyte, lithium-ion battery technology, applied in the field of lithium-ion battery non-aqueous electrolyte, can solve the problems of low electrolyte flash point, runaway battery, thermal breakdown, etc., achieve good conductivity, increase capacity, improve The effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

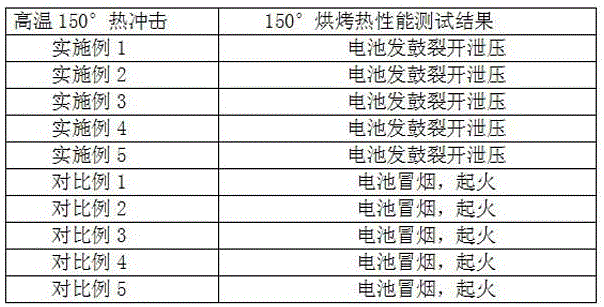

Examples

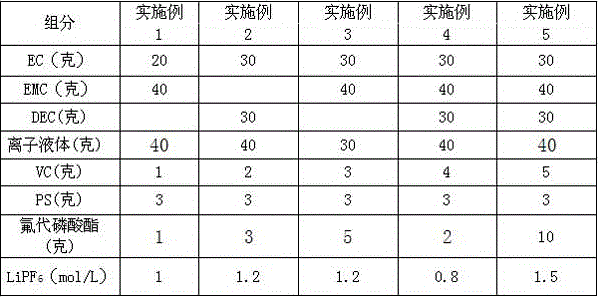

Embodiment 1

[0014] In this example, the electrolyte is prepared in a BRAUN glove box, which is filled with nitrogen gas with a purity of 99.999%, the moisture in the glove box is controlled at ≤5ppm, and the temperature is at room temperature. Mix 20 grams of ethylene carbonate, 40 grams of ethyl methyl carbonate and 40 grams of 1-methyl-3-ethylimidazolium tetrafluoroborate evenly, seal it and put it in a refrigerator until it cools to 8 After ℃, transfer to the glove box, then add LiPF6 in two batches and mix thoroughly to form a non-aqueous electrolyte solution for lithium-ion batteries with a molar concentration of lithium salt of 1 mol / L. Add the total mass of solvent 1 % vinylene carbonate, 3% 1,3-propane sultone, and 1% tris(2,2,2-trifluoroethyl) phosphite are evenly mixed to obtain a lithium-ion non-aqueous electrolyte .

Embodiment 2

[0016] This embodiment is roughly the same as the embodiment, the difference is that 30 grams of ethylene carbonate and 30 grams of diethyl carbonate are mixed uniformly and sealed, and 40 grams of 1,2-dimethyl-3-ethane is used in this embodiment. Mix imidazole hexafluorophosphate evenly, seal it and put it in the refrigerator until it cools to 8°C, then transfer it to the glove box, then add LiPF6 in two batches and mix well to form the molar concentration of the lithium salt is 1.2mol / L The non-aqueous electrolyte of the lithium-ion battery, in the above non-aqueous electrolyte, add 2% vinylene carbonate, 3% 1,3-propane sultone, 3% tris(2,2 , 2-trifluoroethyl) phosphoric acid ester is uniformly mixed to obtain a lithium-ion non-aqueous electrolyte.

Embodiment 3

[0018] The present embodiment is roughly the same as the embodiment, and the difference is that the present embodiment is that 30 grams of ethylene carbonate, 40 grams of ethyl methyl carbonate, 30 grams of diethyl carbonate and 40 grams of 1-methyl-3 - Mix ethylimidazole hexafluorophosphate evenly, seal it and put it in the refrigerator until it cools down to 8°C, then transfer it to the glove box, then add LiPF6 in two batches and mix well to form a lithium salt with a molar concentration of 1.2mol / L The non-aqueous electrolyte of the lithium-ion battery, in the above non-aqueous electrolyte, add 3% vinylene carbonate, 3% 1,3-propane sultone, 5% tris(2,2 , 2-trifluoroethyl) methyl phosphate is evenly mixed to obtain a lithium ion non-aqueous electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com