Formula and method for preparing auricularia-auricula sandwiched crisp fritter

A technology of black fungus and black fungus enzymatic hydrolysis solution, which is applied in the field of preparing thin and crispy black fungus sandwiches, can solve the problems of monotonous product types and low nutritional content, and achieve crisp and tender texture, unique flavor and sensory state, and is conducive to growth and development Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The formula for preparing black fungus sandwich crisps according to the embodiment of the present invention: tomato seasoning powder, black fungus enzymolysis solution, protein powder and water; according to weight percentage: black fungus enzymolysis solution is 20%, tomato seasoning powder 3%, protein powder 2% and 75% water.

[0021] The ratio of tomato seasoning powder as a seasoning is as follows: tomato powder 50% to 60%, salt 2% to 3%, sugar 20% to 30%, monosodium glutamate 1%, yeast extract 1%, flavor nucleotide dina 0.5%, maltodextrin 10% to 13%, hawthorn powder 0.5%.

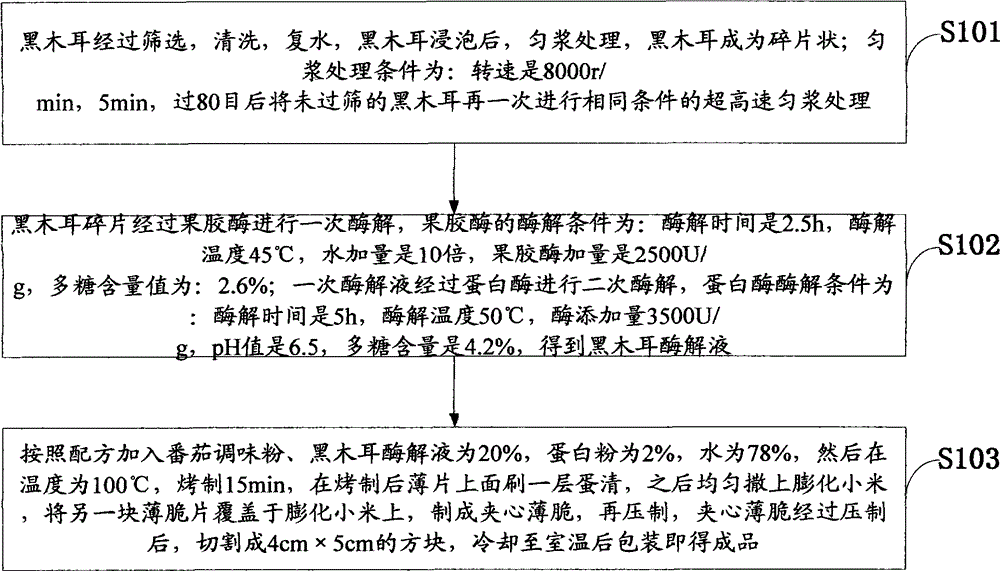

[0022] Such as figure 1 As shown, the method for preparing the crispy black fungus sandwich in the embodiment of the present invention comprises the following steps:

[0023] S101: After the black fungus is screened, washed, rehydrated, soaked and homogenized, the black fungus becomes fragments; the homogenization conditions are: the rotation speed is 8000r / min, 5min, and the unsifted The bl...

Embodiment 1

[0027] Example 1: The specific process steps of black fungus seaweed production include: black fungus screening, cleaning, rehydration, homogenization treatment, primary enzymatic hydrolysis treatment, secondary enzymatic hydrolysis treatment, raw material deployment, roasting, sandwiching, pressing, cutting, After cooling and packaging, the finished product is obtained.

[0028] According to an example of the present invention: the black fungus pretreatment method, the black fungus is screened, washed, rehydrated, and homogenized to obtain black fungus fragments. The homogenization treatment conditions are: the rotating speed is 8000r / min, 5min, after passing through 80 mesh The unscreened black fungus was again subjected to ultra-high-speed homogenization under the same conditions.

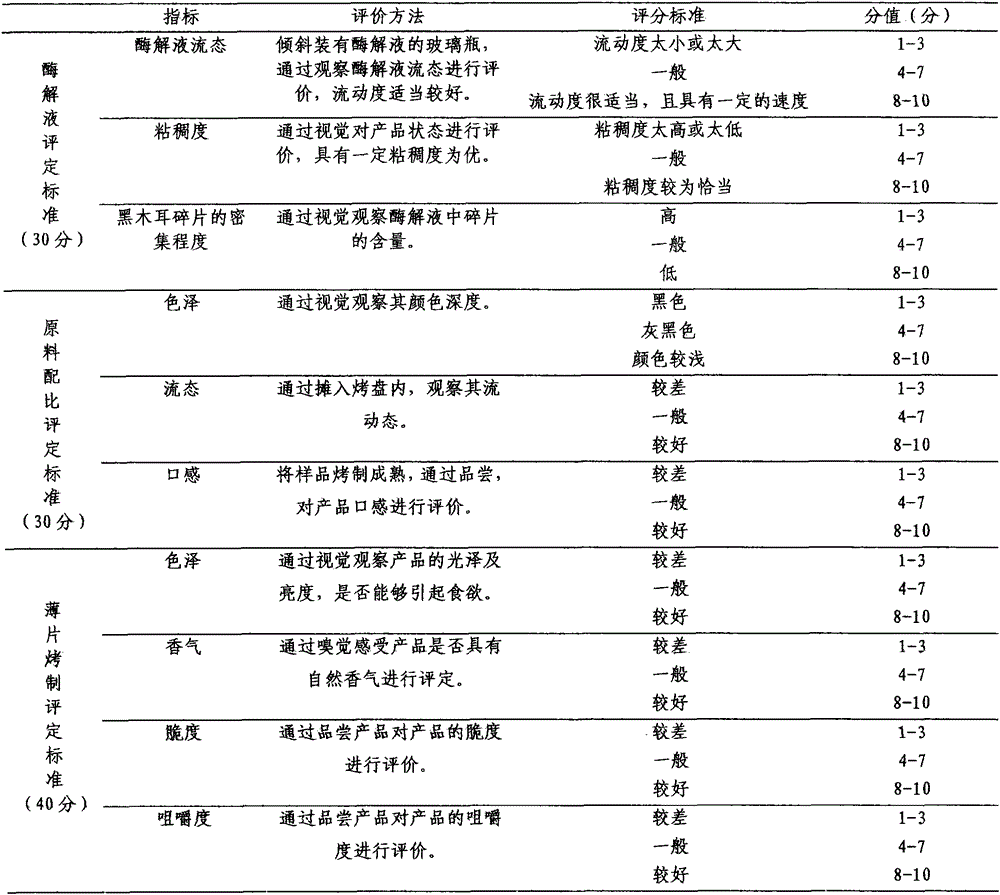

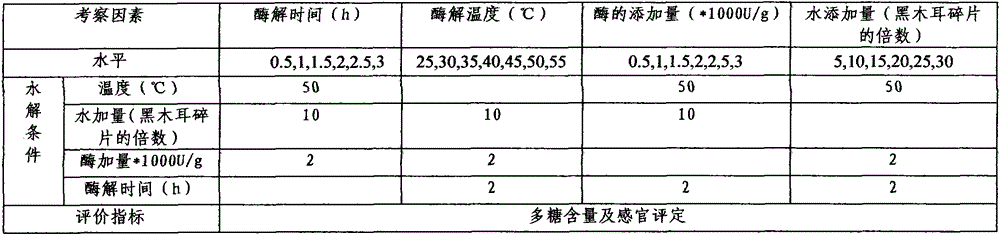

[0029] According to a preferred example of the present invention, the black fungus pretreatment method, the black fungus fragments are optimized with enzymolysis time, temperature, enzyme additi...

Embodiment 2

[0034] Test samples: commercially available dried black fungus; egg protein powder; vegetable oil; pectinase; protease; seasoning;

[0035]Test equipment: double-row four-hole constant temperature water bath: Changzhou National Institute of Experimental Equipment; HH-S4 high temperature and high pressure sterilizer: Hangzhou Kexiao Chemical Equipment Co., Ltd. YXQ-LS; sterile operation table: Suzhou Yida purification experiment Chamber Equipment Co., Ltd.; microplate reader: American Botten Instrument Co., Ltd. (BioTek) Cytation3

[0036] Operation points:

[0037] 1. Screening and rehydration: Select high-quality black fungus, remove impurities, add warm water at a ratio of 1:12 of dry fungus to water, and rehydrate the fungus for 1-3 hours until the black fungus absorbs water completely.

[0038] 2. Homogenization treatment: Use ultra-high-speed homogenization to process soaked black fungus. The processing conditions are: the speed is 8000r / min, 5min, and after passing thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com