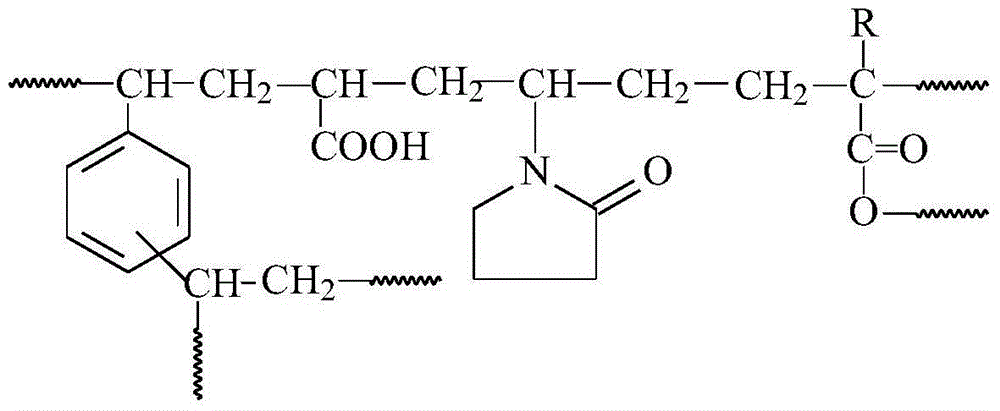

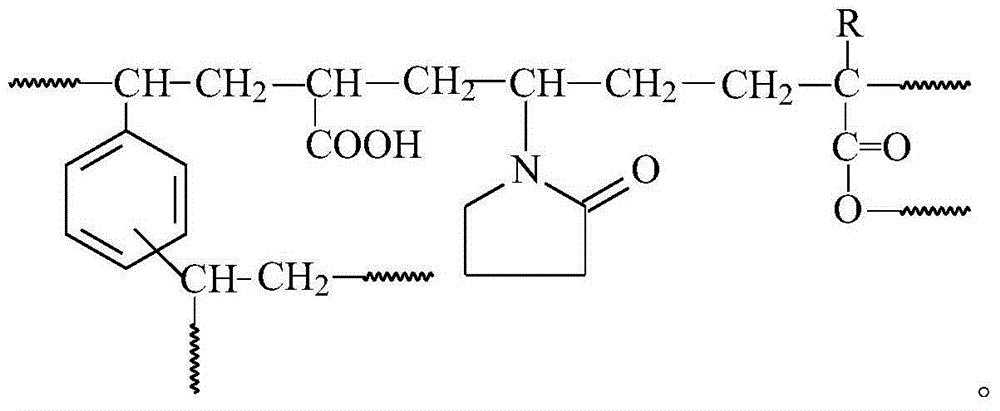

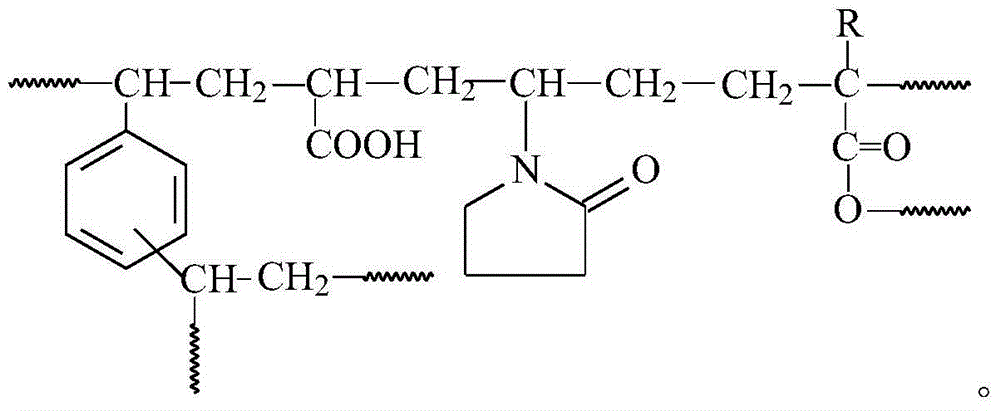

High specific surface area amphoteric adsorption resin containing pyrrolidone bases and preparation method thereof

A technology with high specific surface area and pyrrolidone group, applied in the field of polymer chemistry, can solve the problems of many preparation steps and low specific surface area, and achieve the effects of simple synthesis steps, high product yield and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of amphoteric adsorption resin containing pyrrolidone group with high specific surface area comprises the following steps:

[0021] (1) Add gelatin, trisodium phosphate, disodium hydrogen phosphate, and sodium lignosulfonate to the water phase as dispersants. More specifically, in a 2000 ml flask equipped with a stirring and temperature control device, add 500 ml of water, then add 2.5 g of gelatin, 5 g of trisodium phosphate, 6 g of disodium hydrogen phosphate, and 1 g of sodium lignosulfonate, and stir until dissolved.

[0022] (2) The composition of the oil phase is composed of reactants and porogens. The reactants include cross-linking agents and monomers. The cross-linking agents include aliphatic polyunsaturated ester cross-linking agents and divinylbenzene. Among them, the aliphatic polyunsaturated ester crosslinking agent uses 100 g of diethylene glycol dimethacrylate and 100 g of divinylbenzene; the porogen uses 200 g of isoamyl alcohol a...

Embodiment 2

[0028] The preparation method of amphoteric adsorption resin containing pyrrolidone group with high specific surface area comprises the following steps:

[0029] (1) Add gelatin, trisodium phosphate, disodium hydrogen phosphate, and sodium lignosulfonate to the water phase as dispersants. More specifically, in a 2000 ml flask with a stirring and temperature control device, add 500 ml of water, then add 7.5 g of gelatin, 2.5 g of trisodium phosphate, 2.5 g of disodium hydrogen phosphate, and 0.5 g of sodium lignosulfonate, and stir until dissolved.

[0030] (2) The composition of the oil phase is composed of reactants and porogens. The reactants include cross-linking agents and monomers. The cross-linking agents include aliphatic polyunsaturated ester cross-linking agents and divinylbenzene. Among them, the aliphatic polyunsaturated ester crosslinking agent uses 50 g of diethylene glycol dimethacrylate and 150 g of divinylbenzene; the porogen uses 50 g of isoamyl alcohol and 2...

Embodiment 3

[0036] The preparation method of amphoteric adsorption resin containing pyrrolidone group with high specific surface area comprises the following steps:

[0037] (1) Add gelatin, trisodium phosphate, disodium hydrogen phosphate, and sodium lignosulfonate to the water phase as dispersants. More specifically, in a 2000 ml flask equipped with a stirring and temperature control device, add 500 ml of water, then add 4.5 g of gelatin, 10 g of trisodium phosphate, 15 g of disodium hydrogen phosphate, and 5 g of sodium lignosulfonate, and stir until dissolved.

[0038] (2) The composition of the oil phase is composed of reactants and porogens. The reactants include cross-linking agents and monomers. The cross-linking agents include aliphatic polyunsaturated ester cross-linking agents and divinylbenzene. Among them, the aliphatic polyunsaturated ester crosslinking agent uses 10 g of propyl methacrylate and 90 g of divinylbenzene; the porogen uses 50 g of toluene and 150 g of heptanol; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com