Method and device for recovering carbon disulfide from hydrogen sulfide tail gas in the process of carbon disulfide preparation

A carbon disulfide and preparation process technology, applied in liquefaction, refrigeration and liquefaction, lighting and heating equipment, etc., can solve problems such as waste of hydrogen sulfide gas, waste of hydrogen sulfide gas source materials, strong corrosion, etc., to reduce production consumption and recycle high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

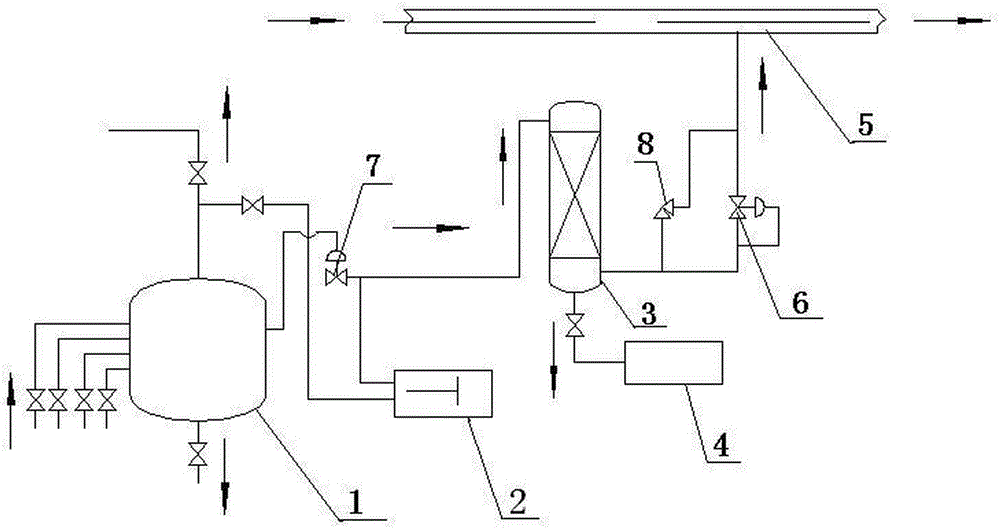

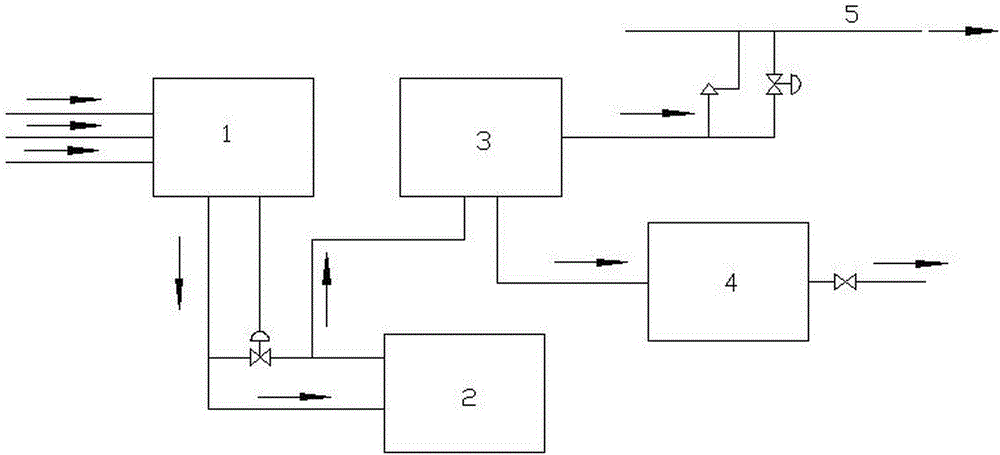

[0025] Carbon disulfide is produced in various links in the production process, such as separation, desulfurization and rectification, which will produce hydrogen sulfide tail gas containing carbon disulfide, and its treatment is relatively scattered. In the prior art, water sealers are generally used to collect CS 2 , and then discharged to the flue outlet of the heating furnace for incineration, the production of sulfur dioxide will pollute the environment, and the process of recycling carbon disulfide will produce industrial sewage.

[0026] The invention provides a method for recovering carbon disulfide from hydrogen sulfide tail gas during the preparation of carbon disulfide, comprising the following steps:

[0027] A. Introduce the hydrogen sulfide tail gas containing carbon disulfide generated in the separation, desulfurization, and fine retention (etc.) links of the carbon disulfide preparation process into the waste gas collector; that is to introduce the hydrogen sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com