Electroplating wastewater cyanide detection method and kit

A detection kit and electroplating wastewater technology, which is applied in the field of analytical chemistry, can solve the problems of distrust and high detection cost, and achieve the effects of simple and fast operation, many detection times, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

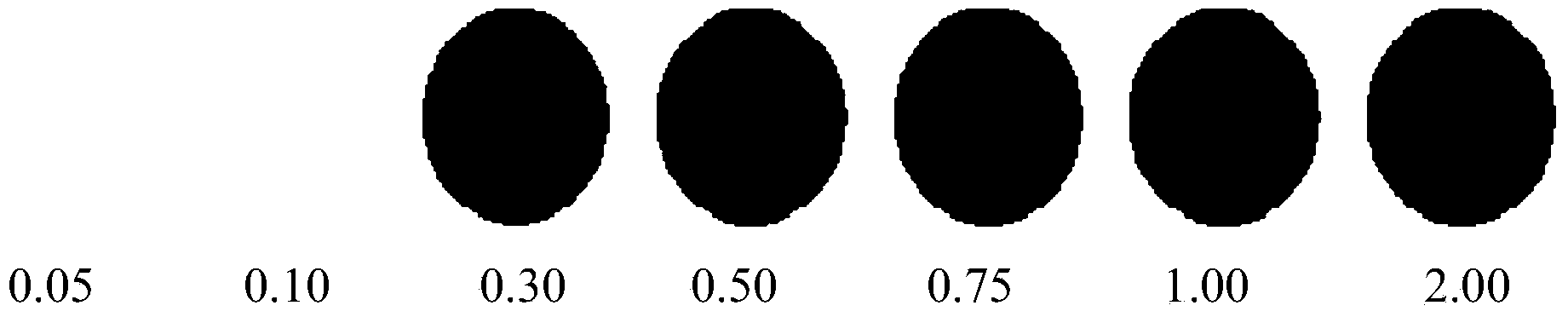

Image

Examples

Embodiment 1

[0035] Preparation of kit: (for 10mL test solution)

[0036] (1) The first reagent: anhydrous potassium dihydrogen phosphate (KH 2 PO 4 )34g with anhydrous disodium hydrogen phosphate (Na 2 HPO 4 ) 35.5g dissolved in pure water and diluted to 100mL, the dosage is 10 drops / time; this reagent is a buffer solution, which stabilizes the pH value of the tested solution, so that the pH value of the tested solution does not change due to volume changes, so as to meet the reaction requirements . Dissolving 34g of potassium dihydrogen phosphate and 35.5g of disodium hydrogen phosphate in 100mL of pure water, the concentration requirement is 10 times that of the original, which is relatively difficult. Process, the exothermic process when disodium hydrogen phosphate dissolves, add the two reagents while stirring until they are all dissolved, the reagents must be kept in plastic bottles;

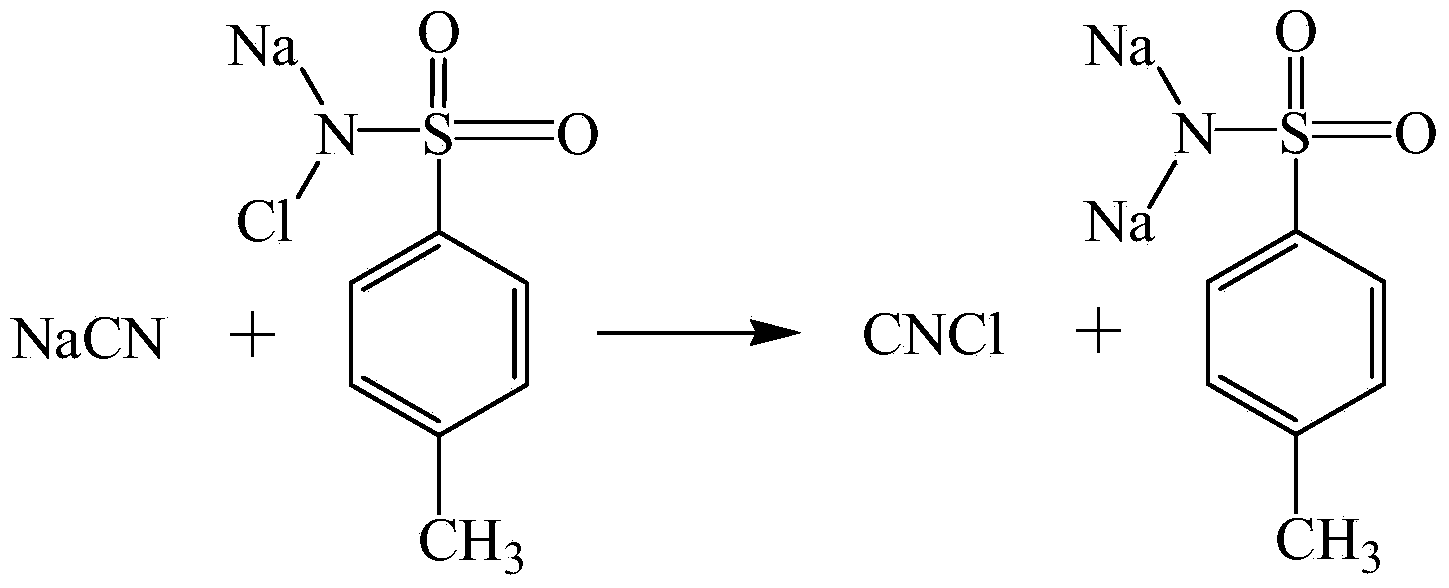

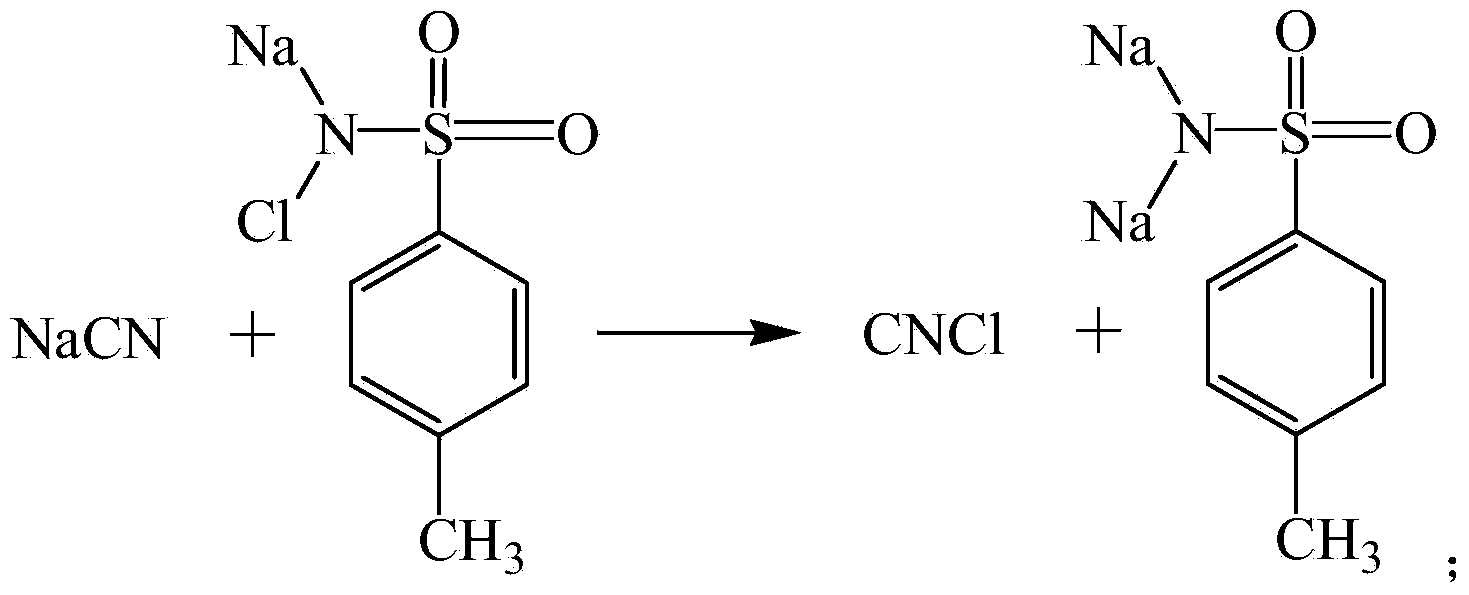

[0037] (2) The second reagent: Chloramine T0.5g, EDTA-2Na1g, sodium chloride 48.5g and mix wel...

Embodiment 2

[0040] Carry out the detection of cyanide in electroplating wastewater with the kit prepared in Example 1: the specific process is as follows:

[0041] (1) Use a 100mL beaker to take a water sample of about 50mL, add a little granular activated carbon, stir well, and let it stand for a few minutes for testing;

[0042] (2) Add 2 drops of 1% phenolphthalein solution to produce red color, add dropwise with 0.5mol / L acetic acid until the red color disappears. This neutralization step can be omitted if the pH value of the water sample shows neutrality. (The following detection methods need to be carried out under neutral conditions)

[0043] (3) Control the cyanide concentration below 1ppm to obtain the tested solution.

[0044] (4) From the above-mentioned pretreated test solution, take 10mL with a 25mL colorimetric tube.

[0045] (5) Add 10 drops of the first reagent dropwise and shake well.

[0046] (6) Pour the second reagent into the colorimetric tube, stopper and shake w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com