Composite solar cell back membrane

A solar cell and composite technology, applied in the direction of adhesive type, circuit, photovoltaic power generation, etc., can solve the problems of shrinking edge, poor flame retardant effect of back film, affecting the service life of solar cell modules, etc., to improve flame retardant performance , Guarantee the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

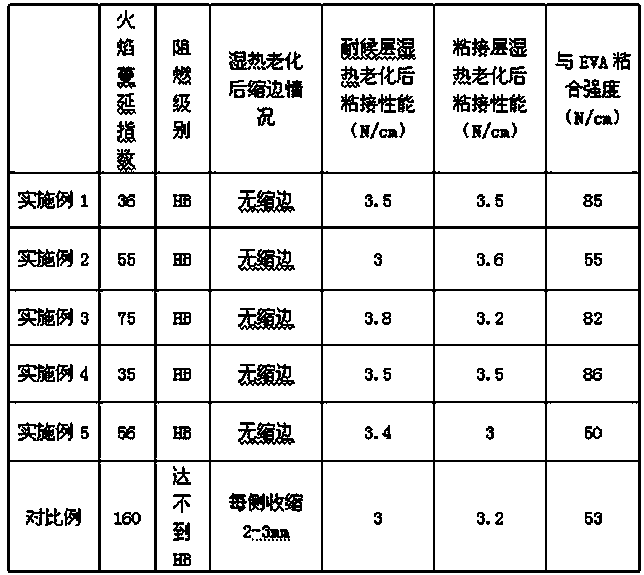

Examples

Embodiment 1

[0033] Adhesive Liofol LA 2692 (manufactured by Henkel) 100 parts

[0034] Isocyanate Liofol LA 7395 (manufactured by Henkel) 15 parts

[0035] Dihydroxy cage silsesquioxane (manufactured by sigma-aldrich) 20 parts

[0036] Methyl isobutyl ketone 95 parts

[0037] 250 parts of ethyl acetate;

[0038]Add 100 parts of Liofol LA 2692, 20 parts of dihydroxycage silsesquioxane, 95 parts of methyl butanone and 250 parts of ethyl acetate into a container equipped with a stirring device and stir evenly for 30 minutes, then add 15 parts of Liofol LA After 7395 was stirred for 20 minutes, it was filtered and packaged. An adhesive coating liquid was prepared.

[0039] On one side of the cleaned and corona-treated substrate PET film, the prepared adhesive coating solution is coated by the slit coating method, and dried at 110°C for 2 minutes to obtain an 8 μm adhesive layer compounded with a 25 μm ETFE fluorine film; The other side of the PET was coated with a 10 μm dry adhesive laye...

Embodiment 2

[0041] Adhesive CA-022 (manufactured by DIC in Japan) 200 parts;

[0042] 15 parts of isocyanate TSH900 (manufactured by DIC Corporation of Japan);

[0043] Monohydroxy cage silsesquioxane (manufactured by sigma-aldrich company) 35 parts;

[0044] Butanone 120 parts;

[0045] 130 parts of ethyl acetate;

[0046] Add 200 parts of CA-022, 35 parts of monohydroxy cage silsesquioxane, 120 parts of butanone and 130 parts of ethyl acetate into a container equipped with a stirring device and stir evenly for 30 minutes, then add 15 parts of isocyanate TSH900 and stir for 20 minutes After 10 minutes, filter and package. An adhesive coating liquid was prepared.

[0047] On one side of the cleaned and corona-treated substrate PET film, apply the prepared adhesive coating solution by the slit coating method, and dry it at 90°C for 1 minute to obtain a 5 μm adhesive layer compounded with a 25 μm PVF fluorine film; The other side of the PET was coated with a 15 μm dry adhesive layer an...

Embodiment 3

[0049] Adhesive CA-017 (manufactured by DIC in Japan) 150 parts;

[0050] 10 parts of isocyanate TSH116 (manufactured by DIC Corporation of Japan);

[0051] Cage silsesquioxane AL0136 (manufactured by American Hybrid Company) 8 parts;

[0052] 200 parts of ethyl acetate;

[0053] 50 parts of methyl isobutyl ketone;

[0054] 30 parts of butyl acetate;

[0055] Add 150 parts of CA-017, 8 parts of AL0136 cage silsesquioxane, 200 parts of ethyl acetate, 30 parts of butyl acetate, and 50 parts of methyl isobutyl ketone into a container equipped with a stirring device and stir evenly for 30 minutes. Then add 10 parts of isocyanate TSH116 and stir for 20 minutes, then filter and package. An adhesive coating liquid was prepared.

[0056] On one side of the cleaned and corona-treated substrate PET film, apply the prepared adhesive coating solution by the slit coating method, and dry it at 110°C for 2 minutes to obtain a 15 μm adhesive layer compounded with a 25 μm PVF fluorine fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com