Two-step fermentation method for efficient production of fermented soybean meal

A technology for fermenting soybean meal and soybean meal, which is applied in animal feed, animal feed, application, etc., can solve problems such as uncomfortable micro-aerobic environment, and achieve the effects of uniform fermentation degree, balanced animal intestinal microbial environment, and simple fermentation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Two-step fermentation is carried out with Bacillus subtilis and plant lactic acid bacteria as the main fermentation strains. The specific steps are as follows:

[0019] (1) Strain activation: Bacillus subtilis was activated with beef extract peptone medium for 2 days, then two rings were placed in 100mL culture solution at 37°C, 200r / min shaking table for 20 hours; lactic acid bacteria were activated with MRS medium for 2 days, and then two rings were placed The rings were cultured statically at 30°C for 48 hours in 100 mL of culture medium.

[0020] (2) Soybean meal crushing: use a pulverizer to crush the soybean meal, and pass through a 60-mesh sieve to obtain soybean meal less than 60 mesh for subsequent fermentation.

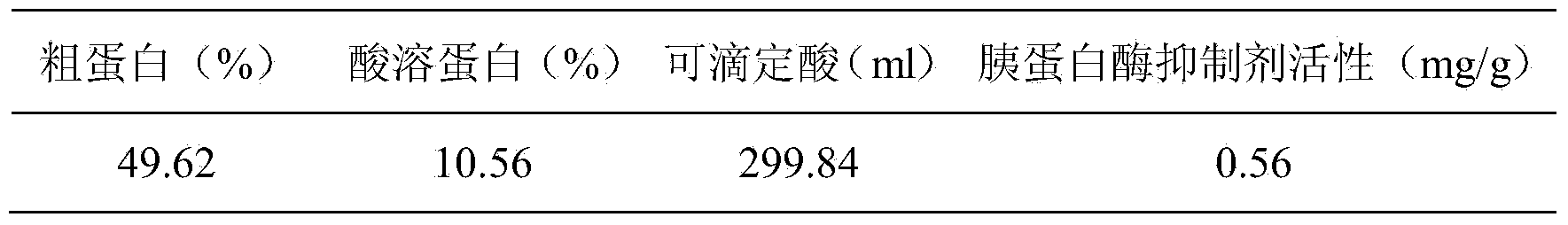

[0021] (3) Shallow plate fermentation: take two wide-mouth can bottles, add 50g of crushed soybean meal and 50mL of water to each bottle, mix evenly, wrap it with eight layers of gauze and newspaper, and sterilize at 121°C for 20 minutes. After cooli...

Embodiment 2

[0026] Two-step fermentation is carried out with Bacillus subtilis, Neurospora and plant lactic acid bacteria as the main fermentation strains, and the specific steps are as follows:

[0027] (1) Strain activation: Bacillus subtilis was activated with beef extract peptone medium for 1-2 days, and then two rings were placed in 100mL culture solution at 37°C, 200r / min shaker for 20h; Neurospora was activated with PDA medium, Take two rings of activated Neurospora spores and disperse them in 100mL of sterilized sterile water, which is the bacterial suspension of Neurobacillus; lactic acid bacteria are activated with MRS medium for 2 days, and then put two rings in 100mL culture solution at 30°C Static culture for 48h.

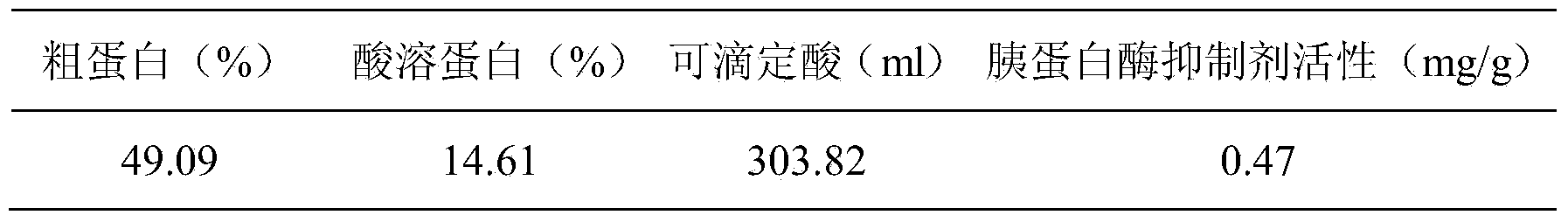

[0028] (2) Shallow dish fermentation: Take four canned jars, add 50g of crushed soybean meal and 50mL of water to each bottle, mix evenly, wrap with eight layers of gauze and newspaper, and sterilize at 121°C for 20min. After cooling down, add 2 mL of Bacillus su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com