Method for preparing high-performance brine lithium-extraction adsorption agent and adsorption agent prepared by method

A lithium adsorption, high-performance technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low pore volume and specific surface area of anion exchange resin, affecting lithium extraction capacity, and low loading of active inorganic particles, etc. The adsorption speed is fast, the service life is ensured, and the service life is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

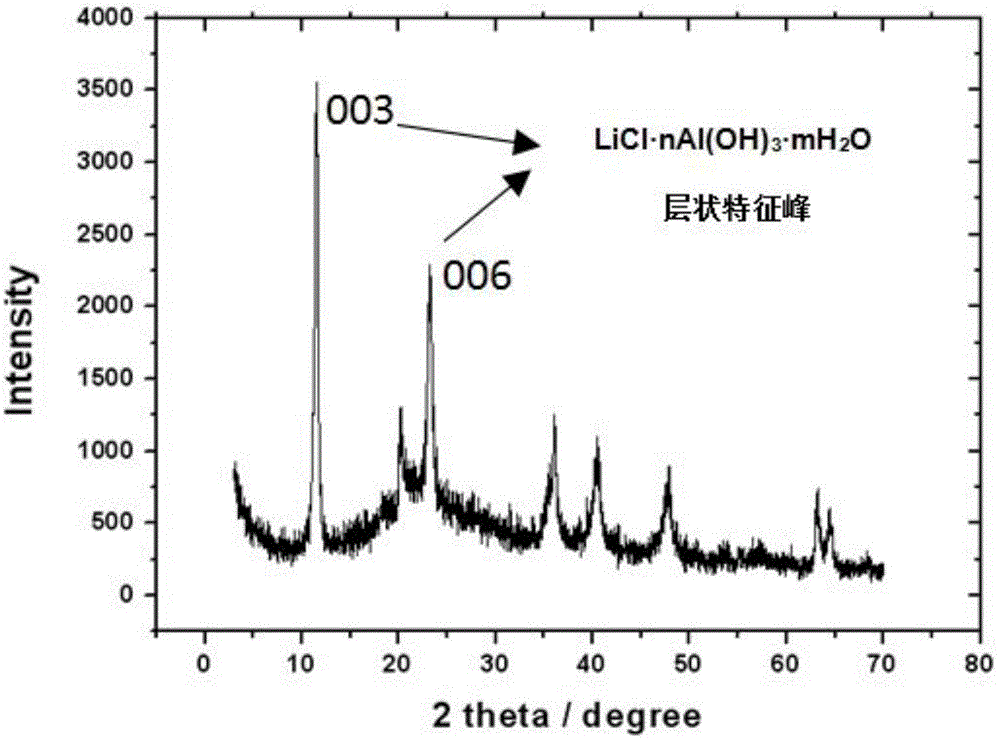

Image

Examples

Embodiment 1

[0031] The method for preparing high-performance brine extracting lithium adsorbent comprises the following steps:

[0032] (1) In a 2000ml flask equipped with a stirring and temperature control device, add water, dispersant, and sodium chloride, and stir at room temperature until dissolved to form an aqueous phase. Wherein, water 500ml; dispersant is gelatin 2.0g, methyl hydroxypropyl cellulose 0.5g; Sodium chloride 25g.

[0033] (2) The oil phase is composed of reactants and porogens, the reactants include monomers and cross-linking agents. Specifically, the monomer is 100 g of butyl methacrylate; the crosslinking agent is 200 g of divinylbenzene and 100 g of diethylene glycol dimethacrylate; the porogen is 150 g of octanol and 50 g of toluene. A total of 600g of oil phase.

[0034] (3) Add the initiator to the oil phase formed in step (2), and stir at room temperature until completely dissolved. The initiator is 1 g of benzoyl peroxide and 1 g of azobisisobutyronitrile. ...

Embodiment 2

[0041] The method for preparing high-performance brine extracting lithium adsorbent comprises the following steps:

[0042] (1) In a 2000ml flask equipped with a stirring and temperature control device, add water, dispersant, and sodium chloride, and stir at room temperature until dissolved to form an aqueous phase. Wherein, water 500ml; dispersant is gelatin 0.5g, polyvinyl alcohol 1.5g; Sodium chloride 50g.

[0043] (2) The oil phase is composed of reactants and porogens, the reactants include monomers and cross-linking agents. Specifically, the monomer is 100 g of butyl methacrylate; the crosslinking agent is 160 g of divinylbenzene and 40 g of diethylene glycol dimethacrylate; the porogen is 100 g of isoamyl alcohol and 200 g of toluene. A total of 600g of oil phase.

[0044] (3) Add the initiator to the oil phase formed in step (2), and stir at room temperature until completely dissolved. The initiator is 1 g of benzoyl peroxide and 2 g of azobisisobutyronitrile.

[0...

Embodiment 3

[0051] The method for preparing high-performance brine extracting lithium adsorbent comprises the following steps:

[0052] (1) In a 2000ml flask equipped with a stirring and temperature control device, add water, dispersant, and sodium chloride, and stir at room temperature until dissolved to form an aqueous phase. Wherein, water 500ml; dispersant is gelatin 2.0g, polyvinyl alcohol 0.5g; Sodium chloride 25g.

[0053] (2) The oil phase is composed of reactants and porogens, the reactants include monomers and cross-linking agents. Specifically, the monomer is 100g of methyl methacrylate, 50g of butyl methacrylate; the crosslinking agent is 200g of divinylbenzene, 50g of allyl methacrylate; the porogen is 150g of isoamyl alcohol, toluene 150g. A total of 700g of oil phase.

[0054] (3) Add the initiator to the oil phase formed in step (2), and stir at room temperature until completely dissolved. The initiator is 2 g of benzoyl peroxide and 2 g of azobisisobutyronitrile.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com