A kind of nickel/noble metal/α-phase nickel hydroxide nanocomposite material, preparation method and application thereof

A nano-composite material, nickel hydroxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve high product purity and yield, solve the effect of operation process, and weaken the tendency of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

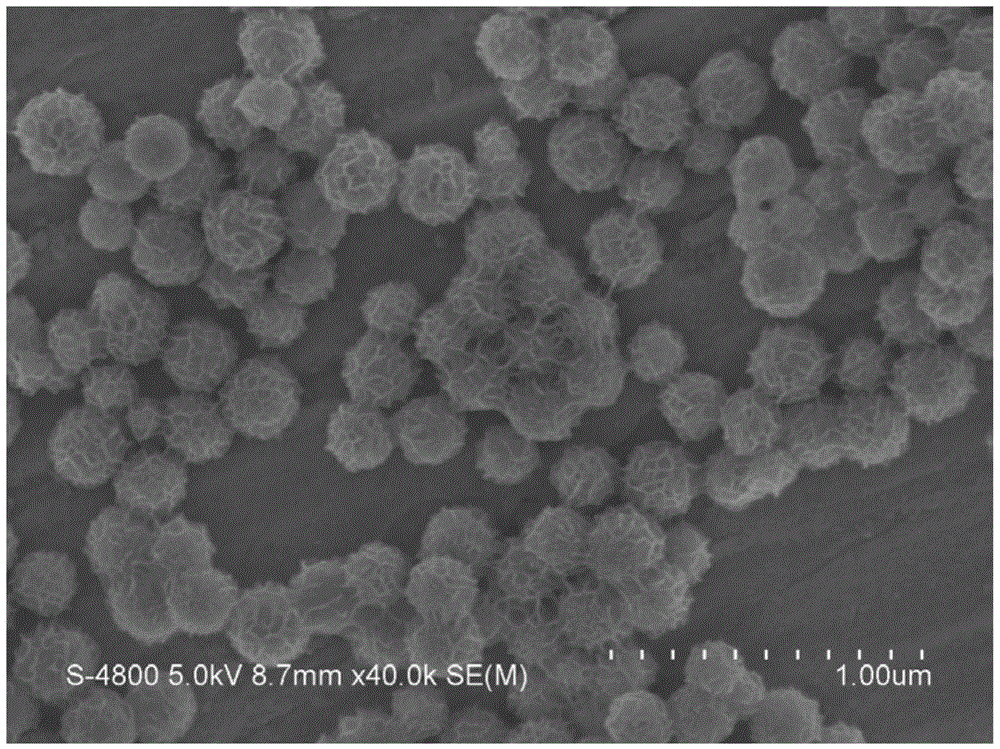

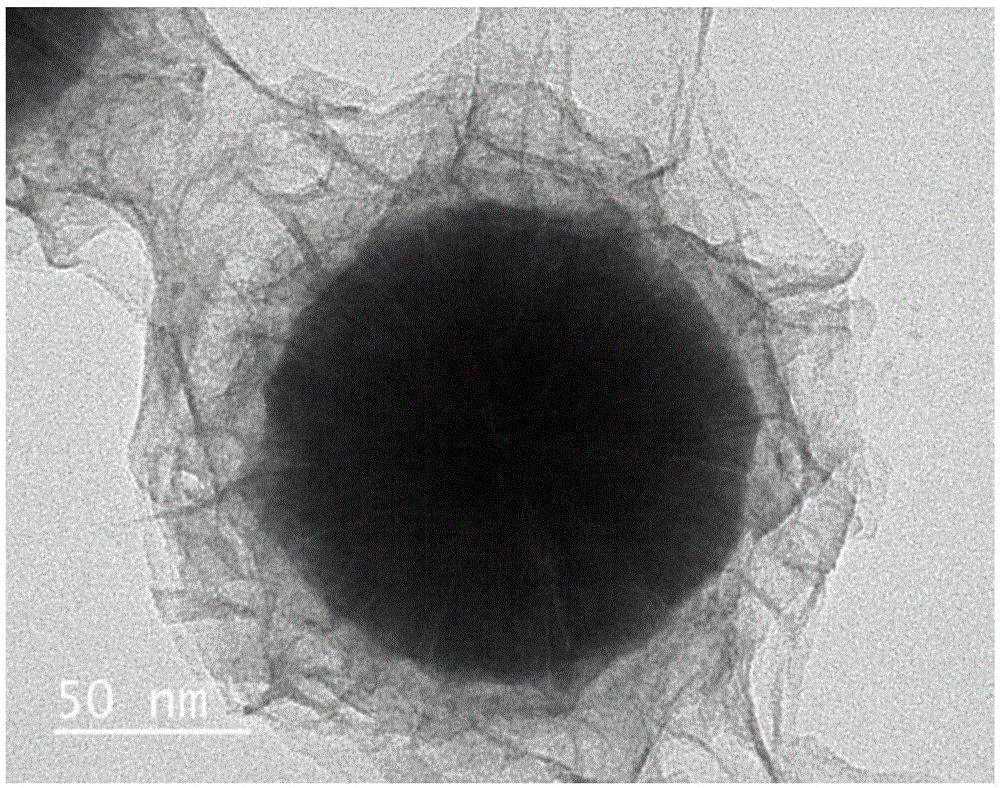

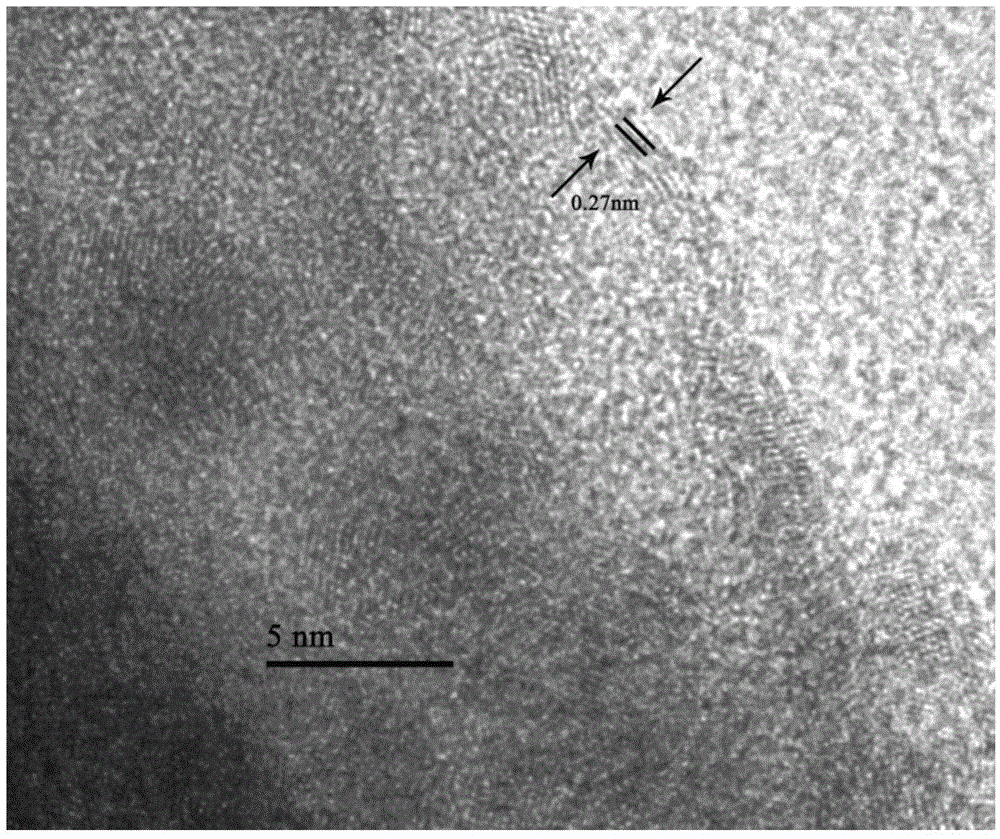

[0034] A nickel / palladium / α-phase nickel hydroxide nanocomposite material, the nanocomposite material has a magnetic core-shell structure, the surface morphology of the magnetic core-shell structure is flower-shaped, the core is nickel nanoparticles, and the palladium shell layer wraps nickel nanoparticles , the outermost layer is a nickel hydroxide protective layer, with an average particle size of 250nm.

[0035] A kind of preparation method of nickel / palladium / alpha phase nickel hydroxide nanocomposite material, the step comprises:

[0036] A. Mix 1mL10mmol·L at room temperature -1 Nickel nitrate solution and 0.15g polyvinylpyrrolidone were dissolved in 50mL water, and ultrasonically mixed to form a mixed solution;

[0037] B. After argon protection for 30 minutes, under continuous stirring at 20°C, add 20mL of newly configured 10mmol / L sodium borohydride solution to the mixed solution prepared in step A, react for 10 minutes, and then inject 8mL0. 5mmol·L -1 K 2 PdCl ...

Embodiment 2

[0043] A nickel / palladium / α-phase nickel hydroxide nanocomposite material, the nanocomposite material has a magnetic core-shell structure, the surface morphology of the magnetic core-shell structure is flower-shaped, the core is nickel nanoparticles, and the palladium shell layer wraps nickel nanoparticles , the outermost layer is a nickel hydroxide protective layer, with an average particle size of 300nm;

[0044] A kind of preparation method of nickel / palladium / alpha phase nickel hydroxide nanocomposite material, the step comprises:

[0045] A. Mix 1mL10mmol·L at room temperature -1 Nickel nitrate solution and 0.15g polyvinylpyrrolidone were dissolved in 50mL water, and ultrasonically mixed to form a mixed solution;

[0046] B. After argon protection for 30 minutes, under stirring at 30°C, add 15 mL of newly configured 20 mmol / L sodium borohydride solution to the mixed solution prepared in step A, react for 10 minutes, and then inject 8 mL into the mixed solution. .5mmol·L...

Embodiment 3

[0049] A nickel / palladium / α-phase nickel hydroxide nanocomposite material, the nanocomposite material has a magnetic core-shell structure, the surface morphology of the magnetic core-shell structure is flower-shaped, the core is nickel nanoparticles, and the palladium shell layer wraps nickel nanoparticles , the outermost layer is a nickel hydroxide protective layer, with an average particle size of 230nm;

[0050] A kind of preparation method of nickel / palladium / nickel hydroxide nano composite material, the step comprises:

[0051] A. Mix 1mL10mmol·L at room temperature -1 Nickel nitrate solution and 0.2g polyvinylpyrrolidone were dissolved in 50mL water, and ultrasonically mixed to form a mixed solution;

[0052] B. After argon protection for 30 minutes, under stirring at 15°C, add 10 mL of newly configured 6 mmol / L sodium borohydride solution to the mixed solution prepared in step A, react for 10 minutes, and then inject 8 mL into the mixed solution. .5mmol·L -1 K 2 PdC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com