Filling material used for mining remained gateway along goafs

A technology of filling materials and gob entry retention, applied in the field of filling materials, can solve the problems of air leakage in gobs, slow increase in material strength, and low initial strength, and achieve the effects of high filling quality, fast increase in strength, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

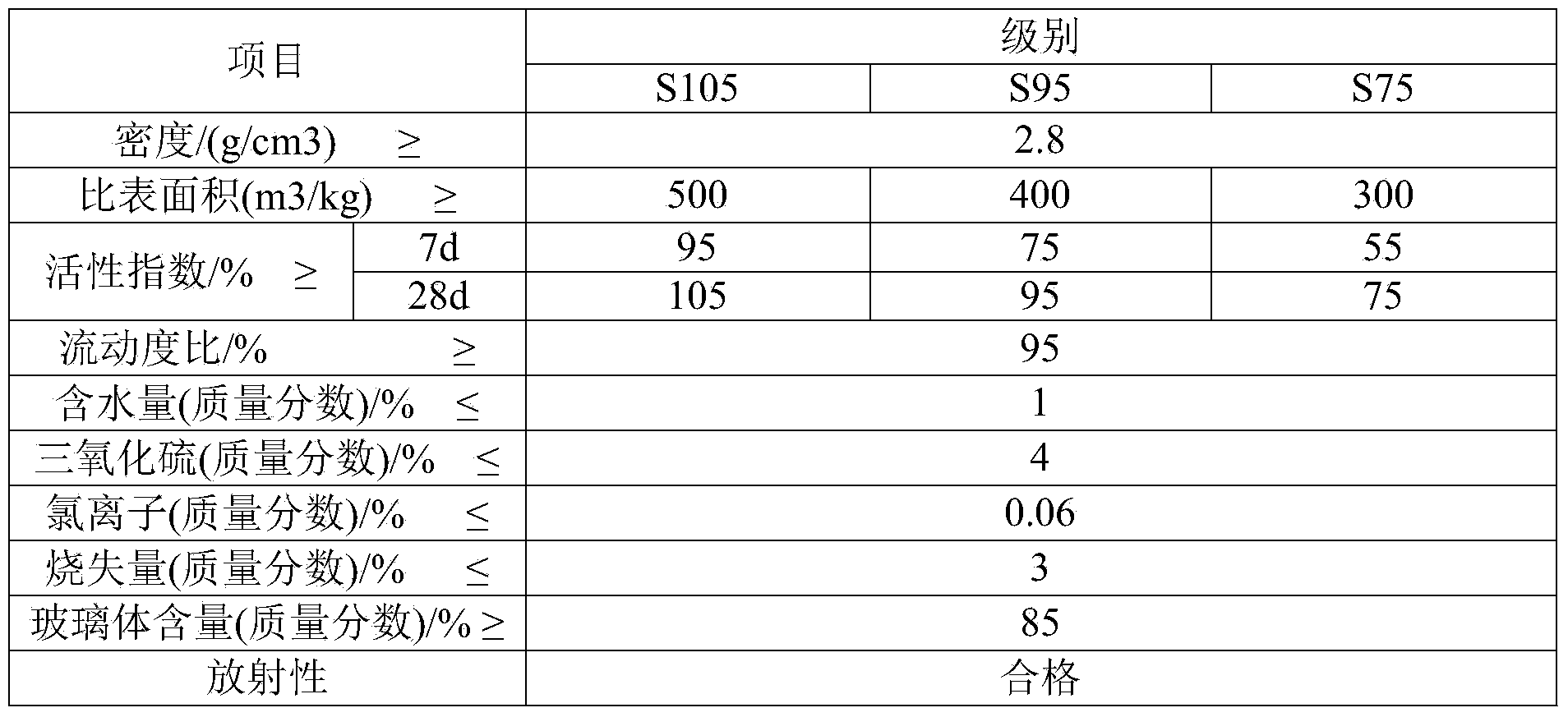

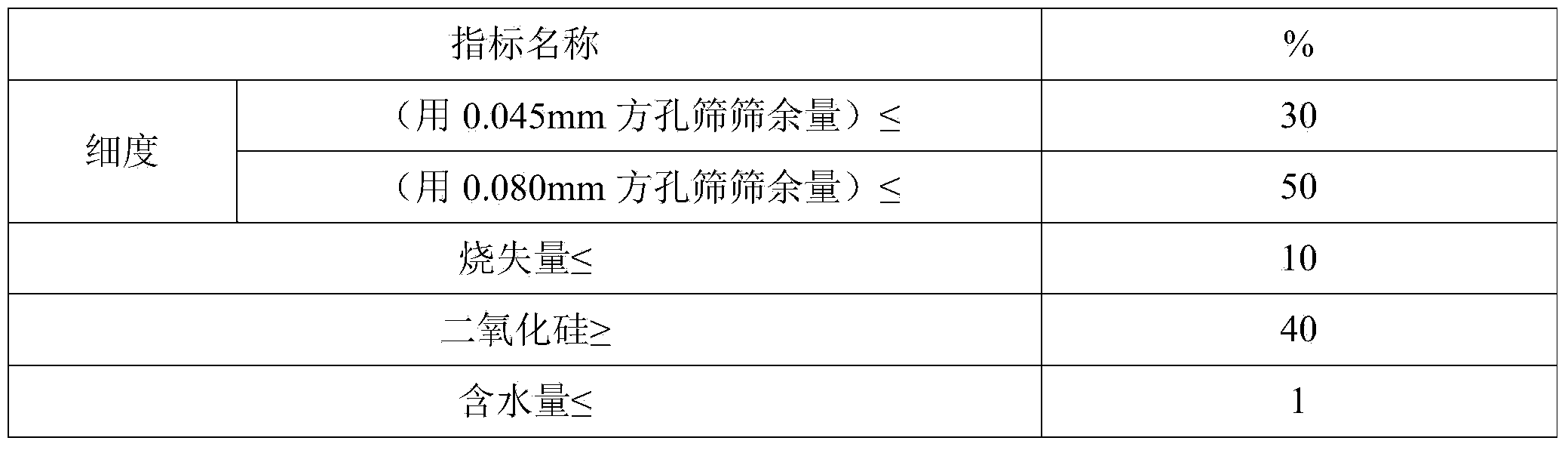

[0039] In the present invention, the cement adopts PO42.5 Portland cement, fly ash, slag powder, and quicklime powder to be transported into the storage tank by a tank truck, and the red mud is dried and ground to more than 200 meshes and carried by a bucket elevator. Storage tank.

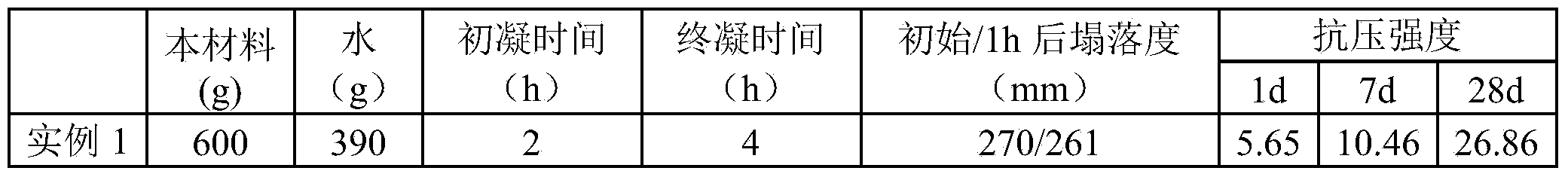

[0040] During production, the proportions are as follows: fly ash is 43kg, red mud is 20kg, quicklime powder is 6kg, slag fine powder is 15kg, portland cement is 10kg, early strength component is 5.0kg, water reducing component is 0.025kg, The expansion component is 0.005kg. Cement, fly ash, slag fine powder, quicklime powder and red mud enter the dry powder mixer through the screw conveyor, and the rest of the small materials can be manually input through the small material port. The materials are stirred in the dry powder mixer for 4 minutes and then packed in bags. Pack into bags, specification 50kg / bag.

[0041] The mass ratio of the early strength component is silica fume: sodium sulfate: s...

Embodiment 2

[0043] In the present invention, the cement adopts PO42.5 Portland cement, fly ash, slag powder, and quicklime powder to be transported into the storage tank by a tank truck, and the red mud is dried and ground to 250 meshes, and is lifted into the storage tank by a bucket elevator. Storage tank.

[0044] During production, the proportions are as follows: fly ash is 35kg, red mud is 35kg, quicklime powder is 15kg, slag powder is 10kg, portland cement is 2kg, early strength component is 3.85kg, water reducing component is 0.015kg, The expansion component is 0.009kg. Cement, fly ash, slag fine powder, quicklime powder and red mud enter the dry powder mixer through the screw conveyor, and the rest of the small materials can be manually input through the small material port. The materials are stirred in the dry powder mixer for 3 minutes and then packed in bags. Pack into bags, specification 50Kg / bag.

[0045] The mass ratio of the early strength component is silica fume: sodium...

Embodiment 3

[0047] In the present invention, the cement adopts PO42.5 Portland cement, fly ash, slag powder, and quicklime powder to be transported into the storage tank by a tank truck, and the red mud is dried and ground to 300 meshes, and is lifted into the storage tank by a bucket elevator. Storage tank.

[0048] During production, the proportions are as follows: fly ash is 55kg, red mud is 30kg, quicklime powder is 5kg, slag powder is 5kg, portland cement is 4.5kg, early strength component is 0.3kg, water reducing component is 0.015kg , The expansion component is 0.005kg. Cement, fly ash, slag micropowder, quicklime powder and red mud enter the dry powder mixer through the screw conveyor, and the rest of the small materials can be manually input through the small feed port. The materials are stirred in the dry powder mixer for 5 minutes and then packed in bags. Pack into bags, specification 50Kg / bag.

[0049] The mass ratio of the early strength component is silica fume: sodium sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com