Method for preparing and purifying naringin

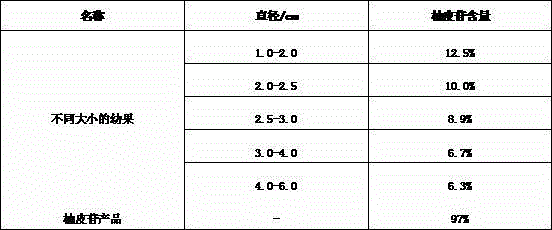

A purification method and naringin technology are applied in the field of preparation and purification of naringin, which can solve the problems of long production process and high cost, and achieve the effects of low production cost, economic value creation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Chromatographic conditions for naringin analysis: chromatographic column (XDB-C18, 4.6 mm×150 mm, 5 μm); mobile phase (methanol:water:phosphoric acid=35:65:0.2); flow rate 1.0 ml / min; column oven ( 30°C); injection volume 20 μl; detection wavelength (λ=283 nm).

[0019] Reference substance solution preparation: Accurately weigh 25.0 mg of naringin reference substance in a 100 ml volumetric flask, add 1 ml of methanol to dissolve, then add water to the mark, shake well, take 1-2 ml and filter with a 0.45 μm microporous membrane to make It is the naringin reference solution.

[0020] Raw material solution preparation: Accurately weigh three parts of about 0.5 g of raw material and place them in a 250 ml corked Erlenmeyer flask, accurately add 100.0 ml of 50% ethanol (volume fraction), seal the plug, and weigh it. Soak the triangular flask in a 60°C water bath for 30 minutes, shake well, and ultrasonically shake at room temperature for 30 minutes, take out and dry the bot...

example 2

[0026] Crush the young pomelo fruit to about 10 meshes, weigh 40g into a 250ml Erlenmeyer flask with a stopper, add 100ml of water, seal it tightly, take a water bath at 95°C for 60 minutes, filter, and extract the filter residue once again with 100ml of water; combine the filtrates in In a 500ml beaker, cool to 30°C with a tap water bath, add a small amount of naringin crystals and a magnetic rotor, stir on a magnetic stirrer at 100r / min for 2 hours, a large amount of crystals precipitate, filter, and dry to obtain 2.43g of light yellow powder The solid was 94% pure by HPLC analysis.

example 3

[0028] Take 200kg of pomelo young fruit, crush it, pour it into the extraction kettle, inject 400kg of water, heat it with steam to 90°C, keep it warm for 1h, release the extract, and extract the filter residue twice with 400kg of water; Filtrate the liquid while it is hot, transfer the filtrate to the extraction kettle again, cool it to 35°C with cooling water, add 2g of naringin crystals, stir and crystallize for 4h, stop stirring to allow the crystals to settle, release the supernatant from the side hole, and put the crystallization liquid in the lower layer Put it into a three-legged centrifuge, dehydrate, and wash with a small amount of water to obtain about 20kg of moist light yellow solid, dissolve it again in 100kg of hot water at 90°C, filter it with a diatomaceous earth filter while it is hot, and cool it to 30°C with cooling water under constant stirring. ℃, a large amount of white crystals precipitated, continued stirring for 1 hour, poured the crystalline solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com