Preparation method of gentamicin sulphate C1a

A technology of gentamicin sulfate and gentamicin, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of low bacterial fermentation units, and achieve the production process is simple and easy to operate, fermentation unit high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

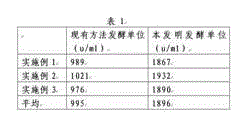

Examples

Embodiment 1

[0049] The preparation method of gentamicin sulfate C1a comprises the following steps:

[0050] 1) Take gentamicin sandy soil spores and place them on the spore slant medium for spore culture, the culture temperature is 35°C, and the culture time is 8-12 days, and the gentamicin spores after slant culture are obtained;

[0051] The preparation method of gentamicin sand spore is:

[0052] a. The formula of sandy soil spore medium is calculated by weight percentage: soluble starch 1.0%, sodium chloride (NaCl) 0.05%, potassium nitrate (KNO 3 ) 0.1%, calcium carbonate (CaCO 3 ) 0.1%, dipotassium hydrogen phosphate (K 2 HPO 4 ) 0.02%, bran 1.8%, magnesium sulfate (MgSO 4 ) 0.02%, agar 2.0%, and the balance is water; the prepared sandy soil spore medium is divided into 100ml in each eggplant bottle, and the volume of the eggplant bottle is 500ml. 0.1MPa, 30 minutes, 120 degrees;

[0053] b. On the ultra-clean workbench, under the protection of the flame, use a sterile inoculat...

Embodiment 2

[0081] The preparation method of gentamicin sulfate C1a comprises the following steps:

[0082] 1) Take gentamicin sandy soil spores and place them on the spore slant medium for spore culture, the culture temperature is 34°C, and the culture time is 8 days, and the gentamicin spores after slant culture are obtained;

[0083] 2) The gentamicin spores cultured on the slant obtained in step 1) were cultured in shake flasks, and the amount of spores cultured in the shake flasks was: dig 0.3cm from the slant of the spores 2 Insert a shake flask, culture temperature is 38 ℃, culture time is 40 hours, obtains gentamicin shake flask mycelia;

[0084] 3) Place the gentamicin shake flask hyphae obtained in step 2) on the seed medium for seed culture, and the insertion amount of the seed culture is: gentamicin shake flask mycelia per thousand of the volume of the seed medium The second is to insert the shake flask seeds, the culture temperature is 38°C, and the culture time is 48 hours ...

Embodiment 3

[0122] The preparation method of gentamicin sulfate C1a comprises the following steps:

[0123] 1) Take gentamicin sandy soil spores and place them on spore slant medium for spore culture, the culture temperature is 38°C, and the culture time is 12 days, and the gentamicin spores after slant culture are obtained;

[0124] 2) The gentamicin spores cultured on the slant obtained in step 1) were cultured in shake flasks, and the amount of spores cultured in the shake flasks was: dig 0.3cm from the slant of the spores 2 Insert a shake flask, culture temperature is 38 ℃, culture time is 40 hours, obtains gentamicin shake flask mycelia;

[0125] 3) Place the gentamicin shake flask hyphae obtained in step 2) on the seed medium for seed culture, and the insertion amount of the seed culture is: gentamicin shake flask mycelia per thousand of the volume of the seed medium The second is to insert the shake flask seeds, the culture temperature is 38°C, and the culture time is 48 hours to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com