Qualitative fiber identification method

A fiber and standard sample technology, applied in the field of component analysis, can solve problems such as error-prone, high labor consumption, environmental pollution, etc., achieve high-efficiency fiber detection, reduce inspection costs, and facilitate popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

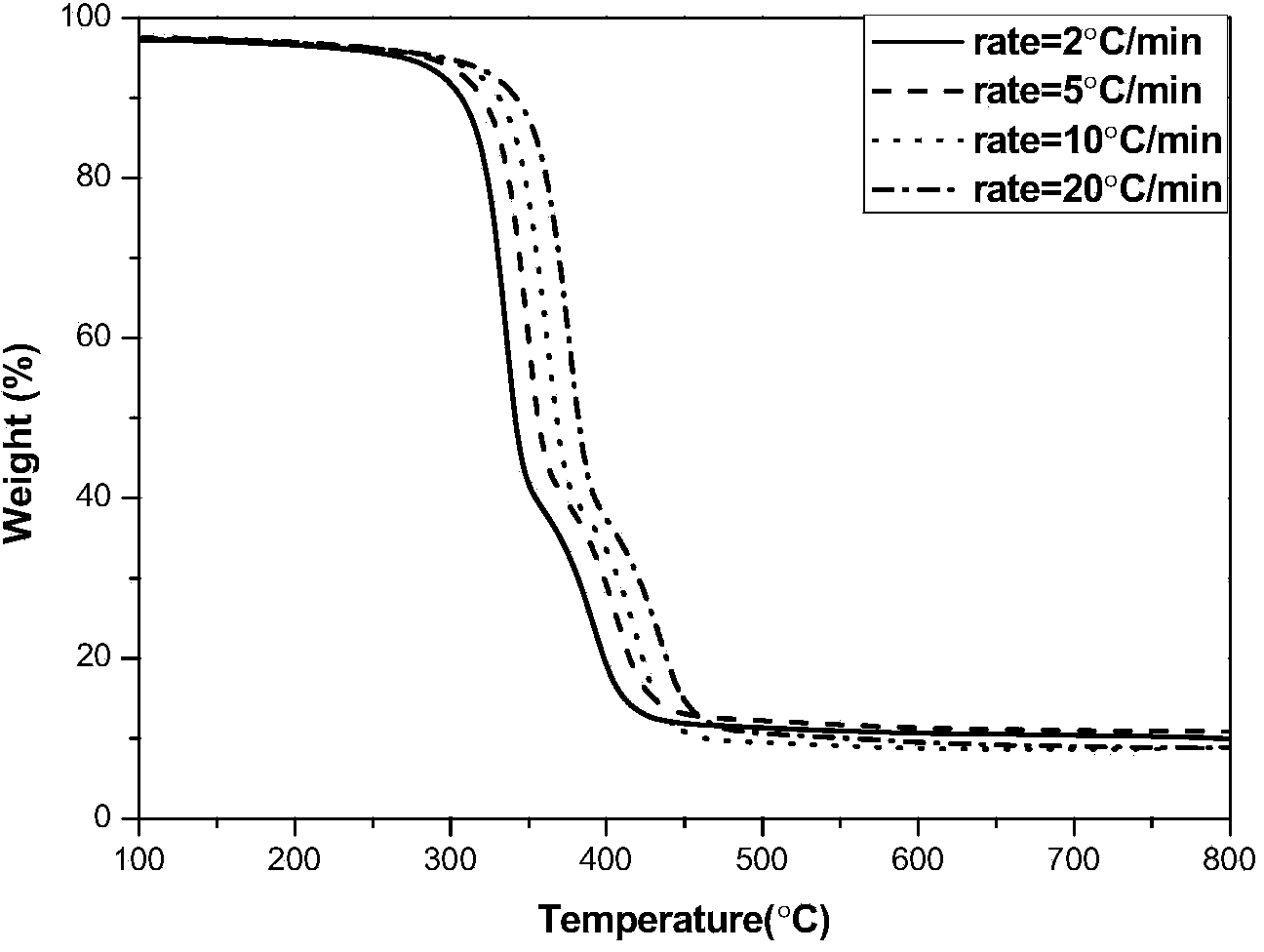

[0043] Embodiment 1 thermogravimetric analysis condition screening

[0044] 1. Screening of environmental atmosphere.

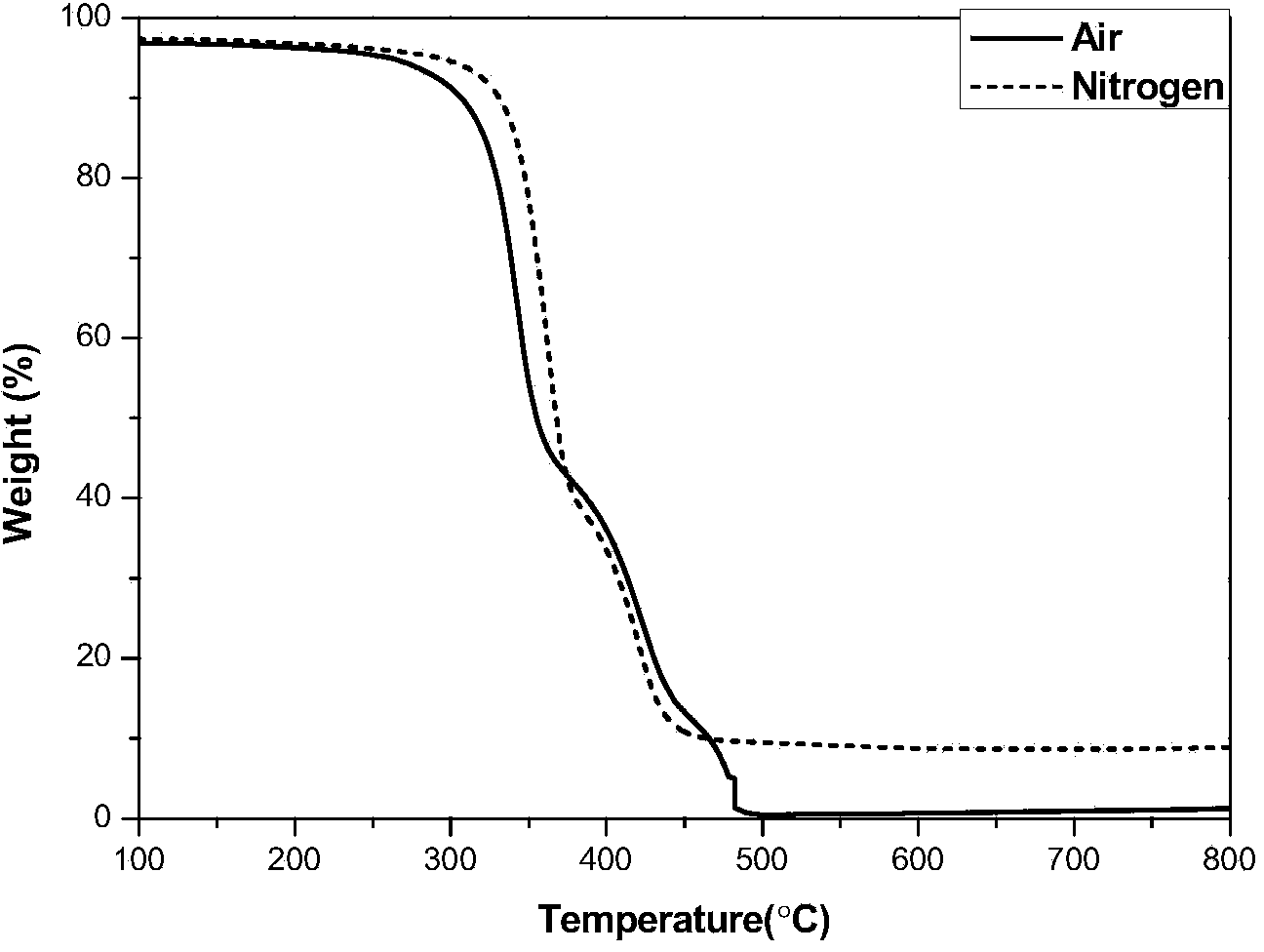

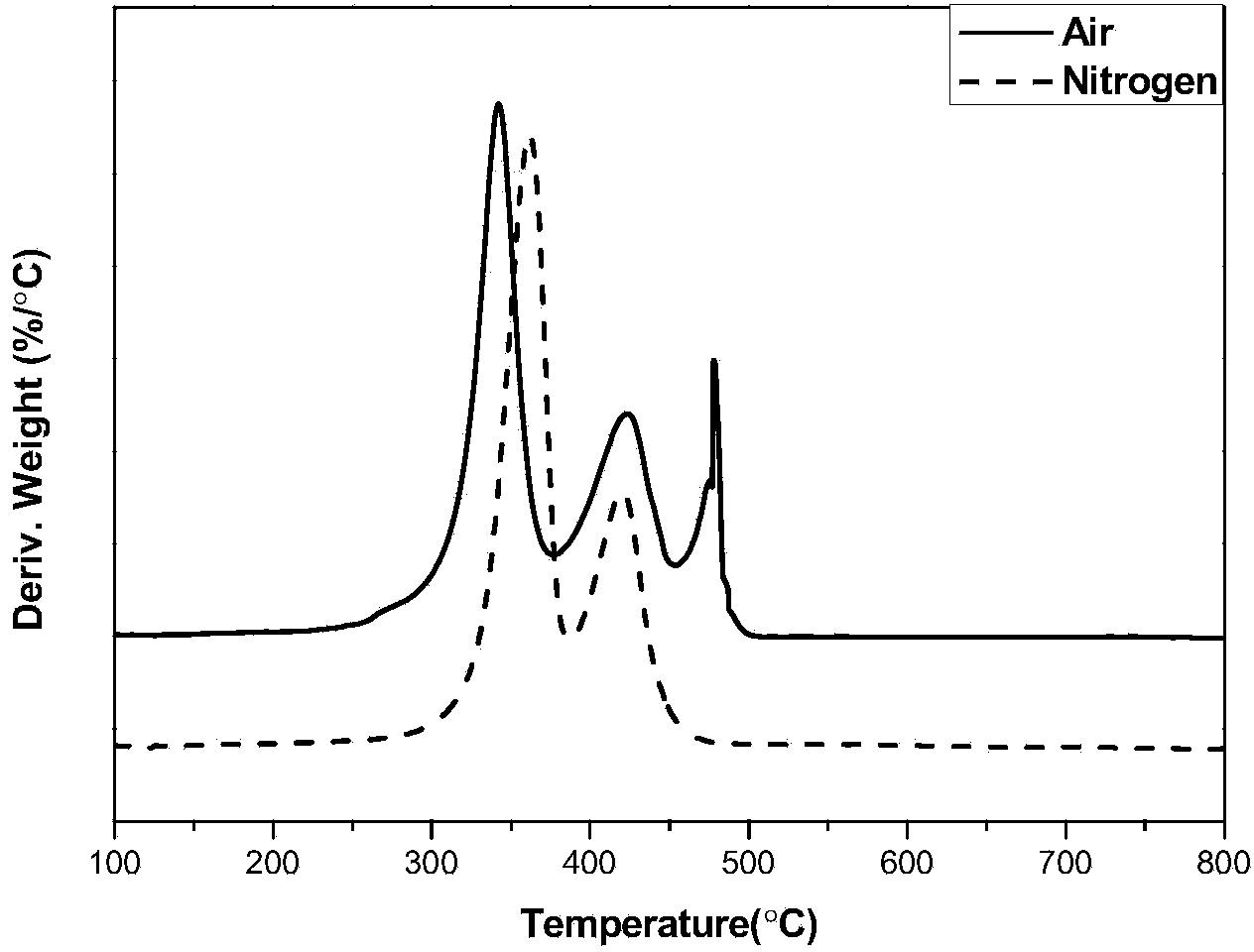

[0045] Select a fiber sample with a composition of 40% polyester fiber and 60% cotton, fully shorten the fiber standard sample to a length of 1-3mm, and mix it evenly, then perform thermogravimetric analysis on the above fiber sample, and the ambient atmosphere is respectively nitrogen Or air, other test conditions are: the initial heating temperature is 50°C, the maximum heating temperature is 800°C, the heating rate is 10°C / min, and the purge air flow is 100mL / min.

[0046] The thermogravimetric (TG) spectrogram and derivative thermogravimetric (DTG) spectrogram obtained by the test are as follows: Figure 1-2 As shown, it can be seen from the spectrum that due to the difference in the ambient atmosphere, in the air atmosphere, because it is an oxidizing atmosphere, there are processes such as oxidative decomposition of organic matter, oxidation of the sam...

Embodiment 2

[0057] A method for qualitative identification of fibers, the operation process is as follows Figure 9 shown, including the following steps. :

[0058] 1) Establish a fiber standard sample database.

[0059] Take different types of fiber standard samples. In this embodiment, the fiber standard samples include: cotton fiber, nylon fiber, acrylic fiber, polyester fiber, high-density polyethylene fiber, and polyphenylene sulfide fiber. Those skilled in the art know that the fiber types in the fiber standard sample database can be selected, added and adjusted according to actual detection needs.

[0060] Use a ball mill or grinder to fully short the fiber standard sample to a length of 1-3 mm, and mix it evenly, and then perform thermogravimetric analysis on the above fiber standard sample. In this embodiment, the selected thermogravimetric analysis test conditions are: Nitrogen atmosphere, the initial heating temperature is 50°C, the maximum heating temperature is 800°C, the ...

Embodiment 3

[0083] In this embodiment, the fiber sample 4 is tested according to the above thermogravimetric analysis conditions and thermogravimetric analysis steps to obtain the thermogravimetric spectrum (TG) of the fiber sample, and calculate the derivative thermogravimetric spectrum (DTG) of the fiber sample , the result is as Figure 19 shown. And the thermogravimetric analysis data shown in Table 4 is obtained by calculating the obtained derivative thermogravimetric spectrum.

[0084] The thermogravimetric analysis data of table 4 fiber sample

[0085] Sample serial number

Decomposition order (n)

Maximum decomposition rate temperature (T d / °C)

Fiber Sample 4

2

(364) / 424

[0086] The thermogravimetric analysis data of the fiber samples obtained above were compared with the decomposition order and maximum decomposition rate temperature in the pre-established fiber standard sample thermogravimetric analysis database. The identification and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com