Array substrate of display device and manufacturing method of array substrate of display device

A technology for array substrates and display devices, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of high power consumption, small redundancy, and low compatibility, and achieve simplified manufacturing process steps, High design redundancy and the effect of reducing parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below based on specific embodiments and drawings, but it is not a limitation of the present invention.

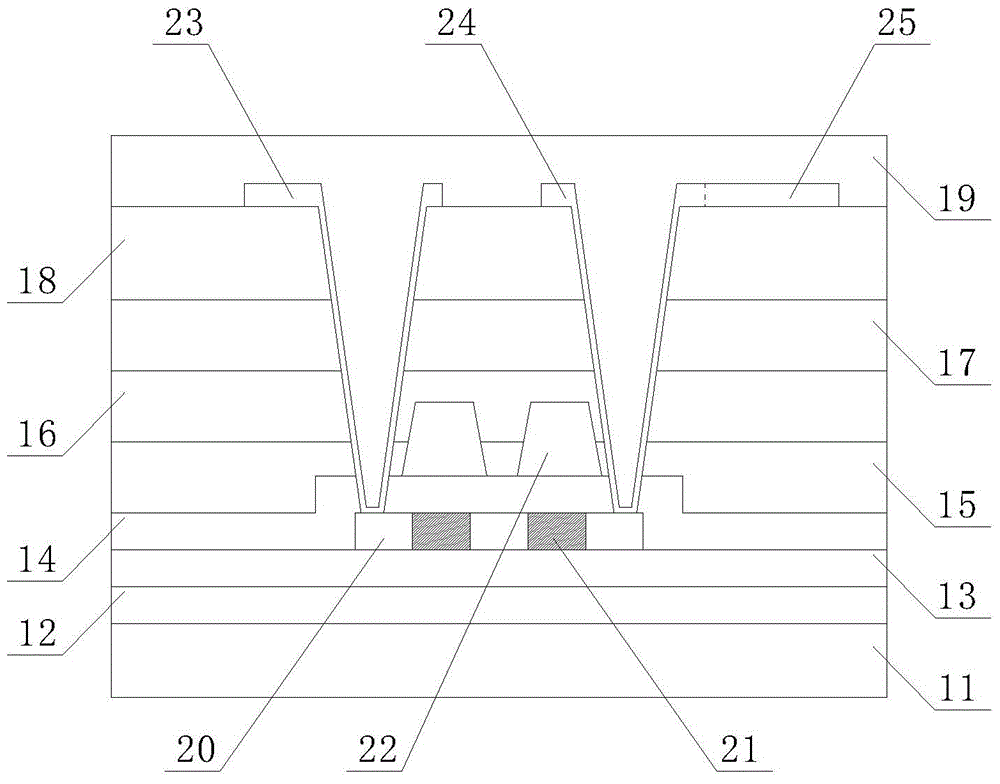

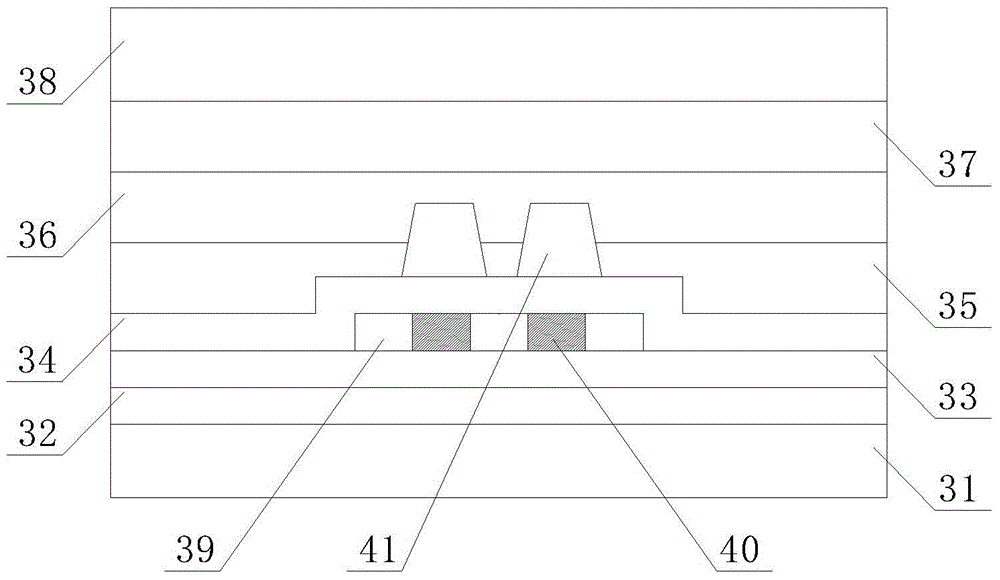

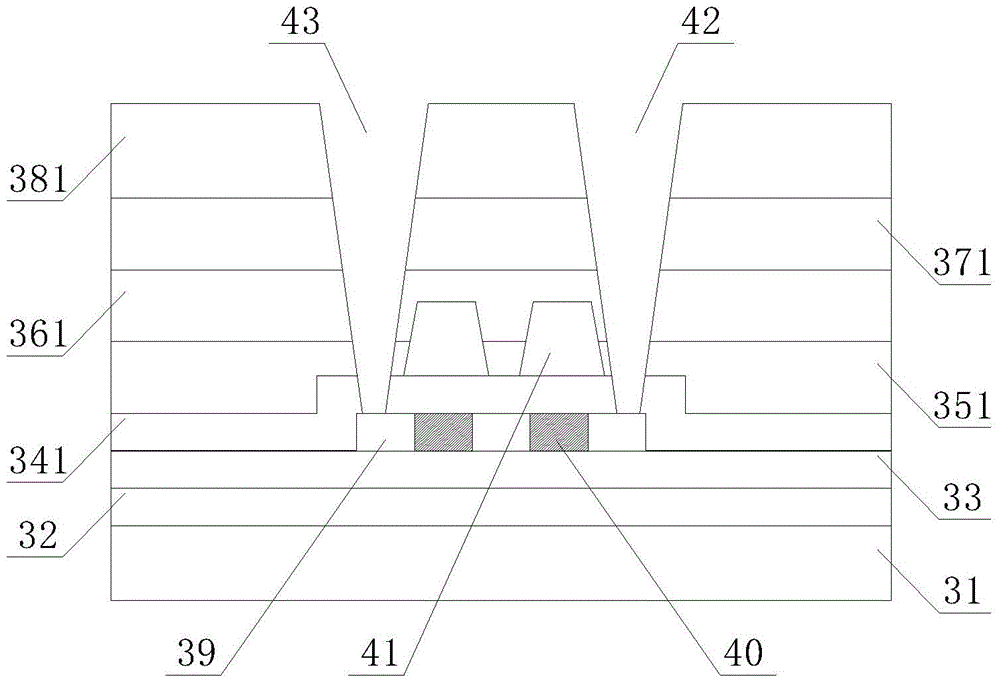

[0052] figure 1 Is a schematic diagram of an embodiment of the array substrate of the display device of the present invention; figure 1 As shown, an array substrate of a display device includes a substrate structure composed of a glass substrate (glass) 11, a bottom silicon nitride layer (BL-SiN) 12, and a bottom silicon oxide layer (BL-SiO) 13, and the bottom The silicon nitride layer 12 covers the upper surface of the glass substrate 11, and the bottom silicon oxide layer 13 covers the upper surface of the bottom silicon nitride layer 12.

[0053] Further, the upper surface of the substrate structure (ie the bottom silicon oxide layer) is also provided with active / drain regions 20 (such as P-type S / D), and between adjacent source / drain regions 20 is also provided The channel region 21, the aforementioned source / drain regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com