Graphene loaded metal nano composite material, and preparation method and application thereof

A nano-composite material and metal-loaded technology, which is applied in the field of nano-material preparation and application, can solve the problem of only 15% and achieve good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

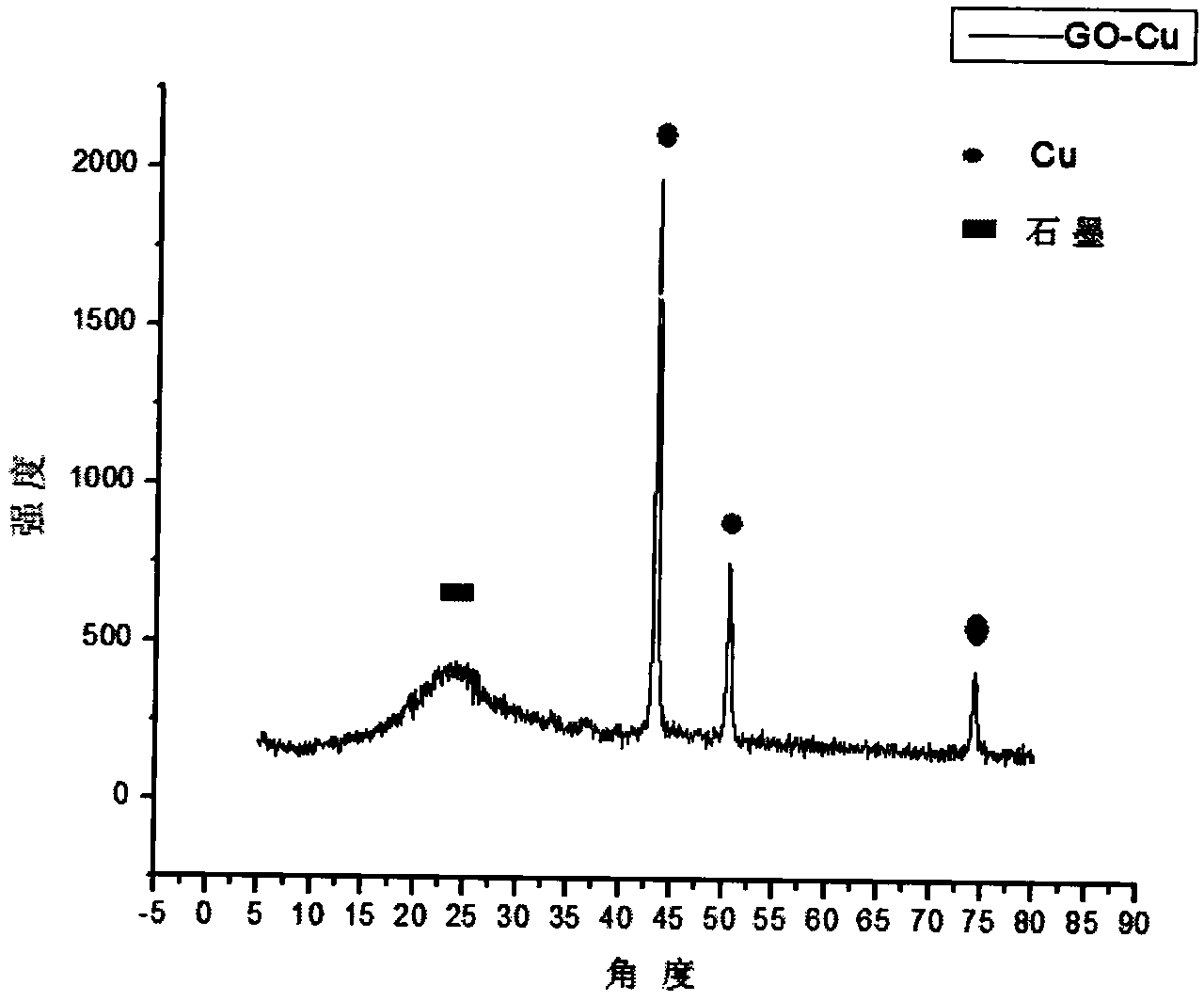

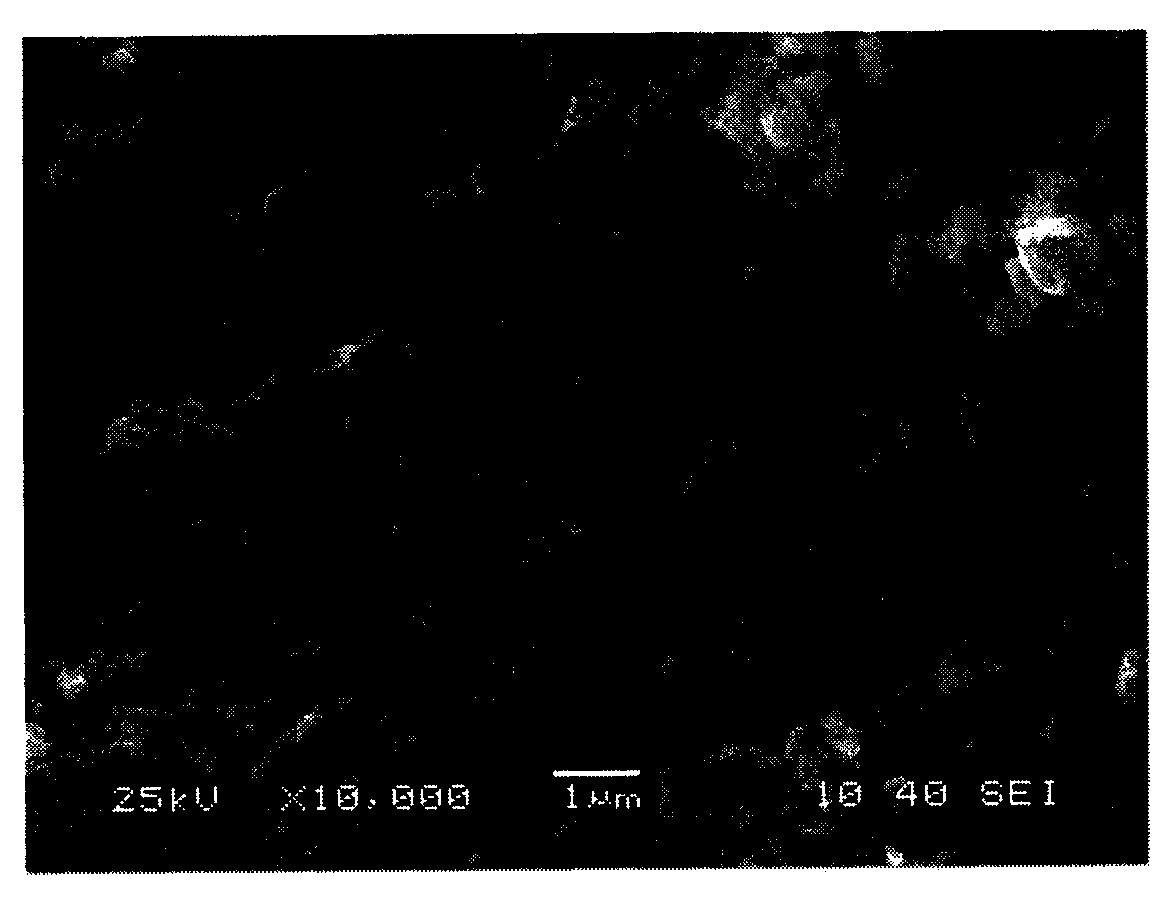

[0022] Embodiment 1: the preparation of graphene supported copper nanocomposite material

[0023] Accurately weigh 375mg metal salt copper sulfate pentahydrate and dissolve it in deionized water to prepare 0.005mol / L copper sulfate pentahydrate solution and an appropriate amount of surfactant sodium citrate, mix it into the graphene oxide deionized aqueous solution, and ultrasonically 1h, make it completely dispersed, react at room temperature for 12h, and prepare a graphene oxide metal salt mixed solution. Add 4.8g of 30mL of 50% NaOH aqueous solution and 4mL of 80% hydrazine hydrate to the above mixed solution successively with a dropping funnel, control the dropping rate to 0.04mL for 1 minute, react at 80°C for 12h, filter, wash with water for 3 times, and wash with ethanol for 3 The second time, the graphene-loaded metal nanocomposite material was obtained by vacuum drying at 60°C. For the results, see figure 1 , the characteristic diffraction peak of graphite oxide disa...

Embodiment 2

[0024] Example 2: Preparation of graphene-supported manganese nanoparticle composites

[0025] According to the reaction conditions of Example 1, the difference is that the metal salt copper sulfate pentahydrate was replaced by manganese sulfate monohydrate, and the graphene-supported metal manganese nanomaterial was obtained after post-reaction treatment.

Embodiment 3

[0026] Embodiment 3: Preparation of graphene-loaded copper-manganese nanoparticle composite material

[0027] According to the reaction conditions of Example 1, the difference is that the metal salt copper sulfate pentahydrate is replaced by a mixed metal salt of manganese sulfate monohydrate and copper sulfate pentahydrate, and the graphene-supported copper-manganese metal nanomaterial is obtained after post-reaction treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com