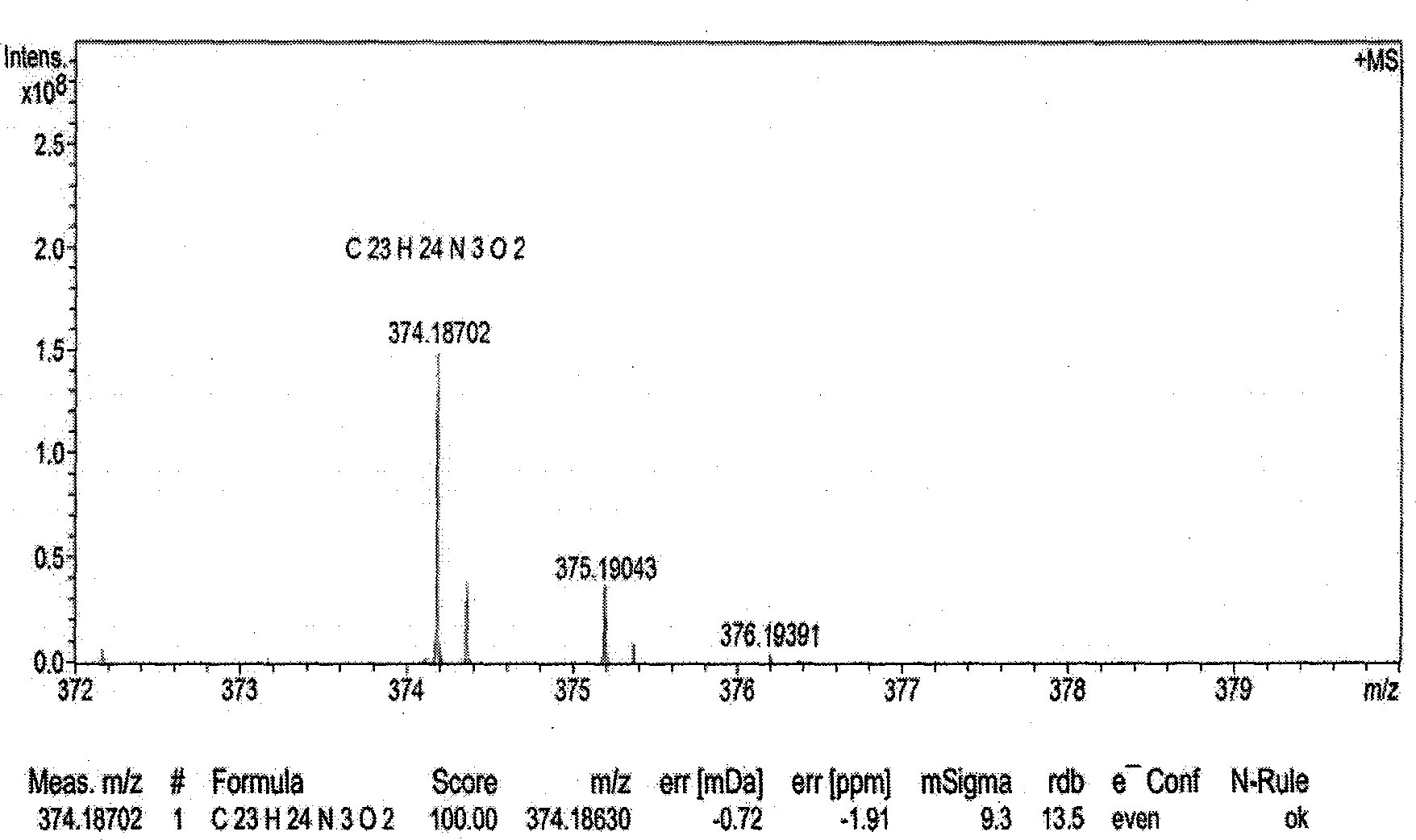

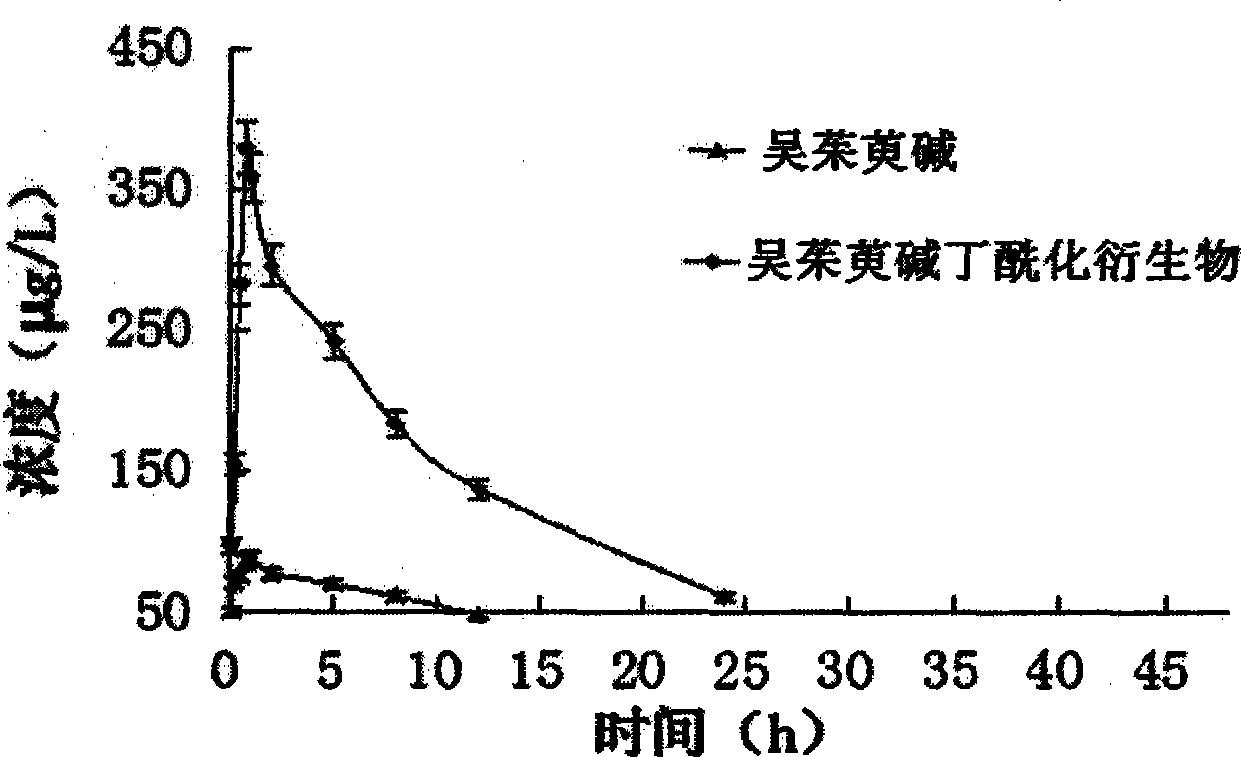

N1-butyrylevodiamine and synthesis method thereof

A technology of butyryl evodiamine and evodiamine, applied in the field of molecular structure and synthesis of N1-butyryl evodiamine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

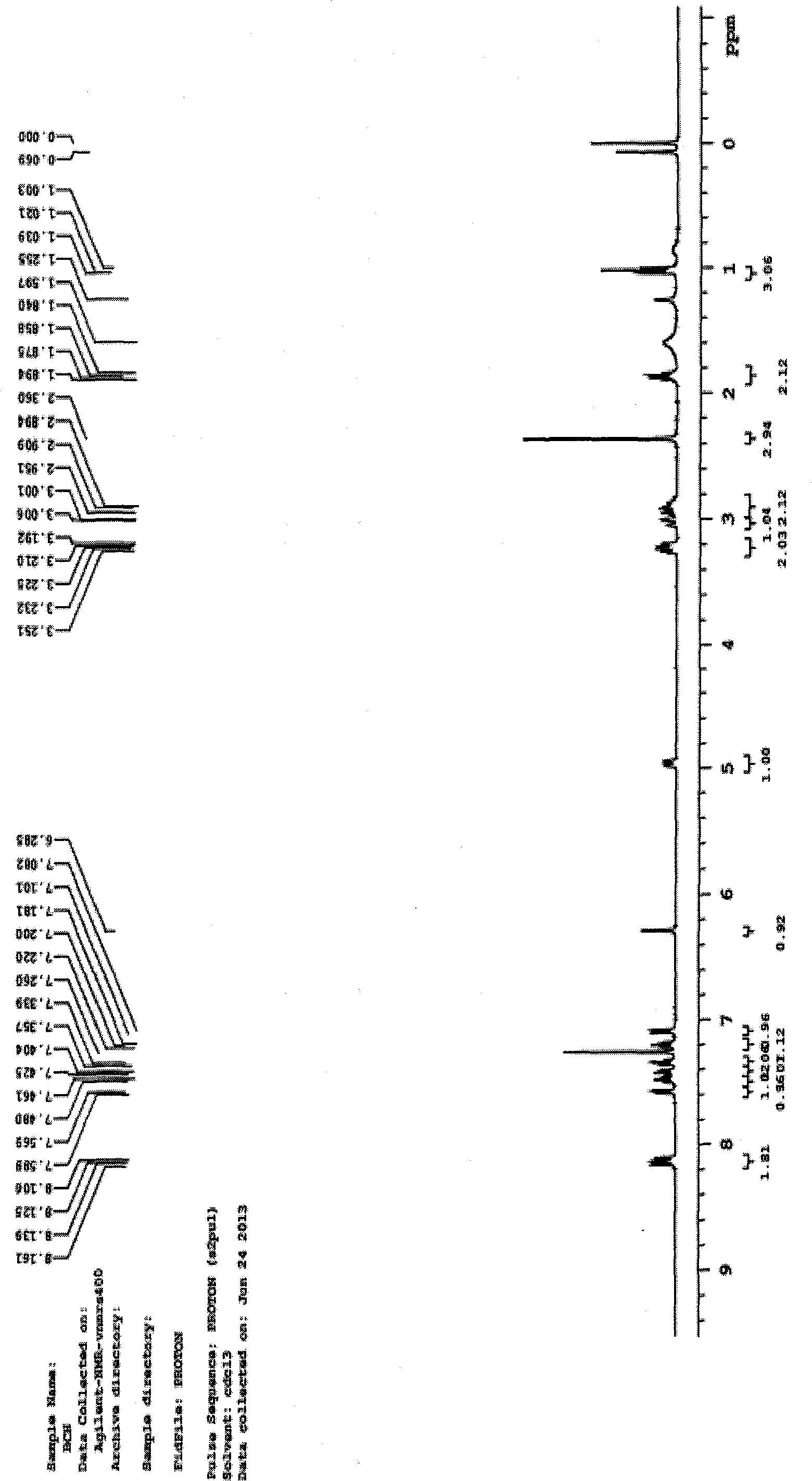

Embodiment 1

[0020] Weigh 0.2g of evodiamine (formula II) and place it in a 50ml round-bottomed flask, add 15mL of N,N-dimethylformamide solvent, ultrasonically dissolve, add 0.1323g of sodium hydride (60%) (at this time, evodiamine The molar ratio to sodium hydride is 1:5), after magnetic stirring for 0.5h, add 0.136mL (20°C; density 1.03g / mL) of n-butyryl chloride (formula III) (at this time, evodiamine and n-butyryl chloride The molar ratio is 1:2), the temperature was slowly raised to 70°C, and the reaction was terminated by magnetic stirring for 18 hours; 40 mL of purified water was added to the reaction solution, left to room temperature, and ethyl acetate was added to extract 3 times (40 mL each time). Collect the upper layer extract, add purified water to wash 3 times (each time 50mL), spin dry the solvent, use ethyl acetate:petroleum ether volume ratio of 1:4 solution as eluent, use silica gel column to separate, on silica gel G250 Samples were spotted on thin-layer plates, using ...

Embodiment 2

[0022]Weigh 0.2g of evodiamine (formula II) and place it in a 50ml round-bottomed flask, add 15mL of N,N-dimethylformamide solvent, ultrasonically dissolve, add 0.2630g of sodium hydride (60%) (at this time, evodiamine The molar ratio to sodium hydride is 1:10), after magnetic stirring for 0.5h, add 0.35mL (20°C; density 1.03g / mL) of n-butyryl chloride (formula III) (at this time, evodiamine and n-butyryl chloride The molar ratio is 1:5), the temperature was slowly raised to 80°C, and the reaction was terminated by magnetic stirring for 24 hours; 40 mL of purified water was added to the reaction solution, left to room temperature, and ethyl acetate was added to extract 3 times (40 mL each time). Collect the upper layer extract, add purified water to wash 3 times (50mL each time), remove the solvent by rotary evaporation, use ethyl acetate:petroleum ether with a volume ratio of 1:4 as the eluent, and use a silica gel column to separate. Samples were spotted on G250 thin-layer p...

Embodiment 3

[0024] Weigh 0.2g of evodiamine (formula II) and place it in a 50ml round-bottomed flask, add 15mL of N,N-dimethylformamide solvent, ultrasonically dissolve, add 0.1323g of sodium hydride (60%) (at this time, evodiamine The molar ratio to sodium hydride is 1:5), after magnetic stirring for 0.5h, add 0.401mL (20°C; density 1.03g / mL) of n-butyryl chloride (formula III) (at this time, evodiamine and n-butyryl chloride The molar ratio is 1:6), the temperature was slowly raised to 70°C, and the reaction was terminated by magnetic stirring for 18 hours; 40 mL of purified water was added to the reaction solution, left to room temperature, and ethyl acetate was added to extract 3 times (40 mL each time). Collect the upper layer extract, add purified water to wash 3 times (each time 50mL), spin dry the solvent, use ethyl acetate:petroleum ether volume ratio of 1:4 solution as eluent, use silica gel column to separate, on silica gel G250 Samples were spotted on thin-layer plates, using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com