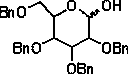

Method for preparing tetrabenzyl pyran type hexose

A technology of tetrabenzylpyran-type and six-carbon sugar, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., to achieve the effects of less side reactions, simplified post-treatment methods, and improved purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

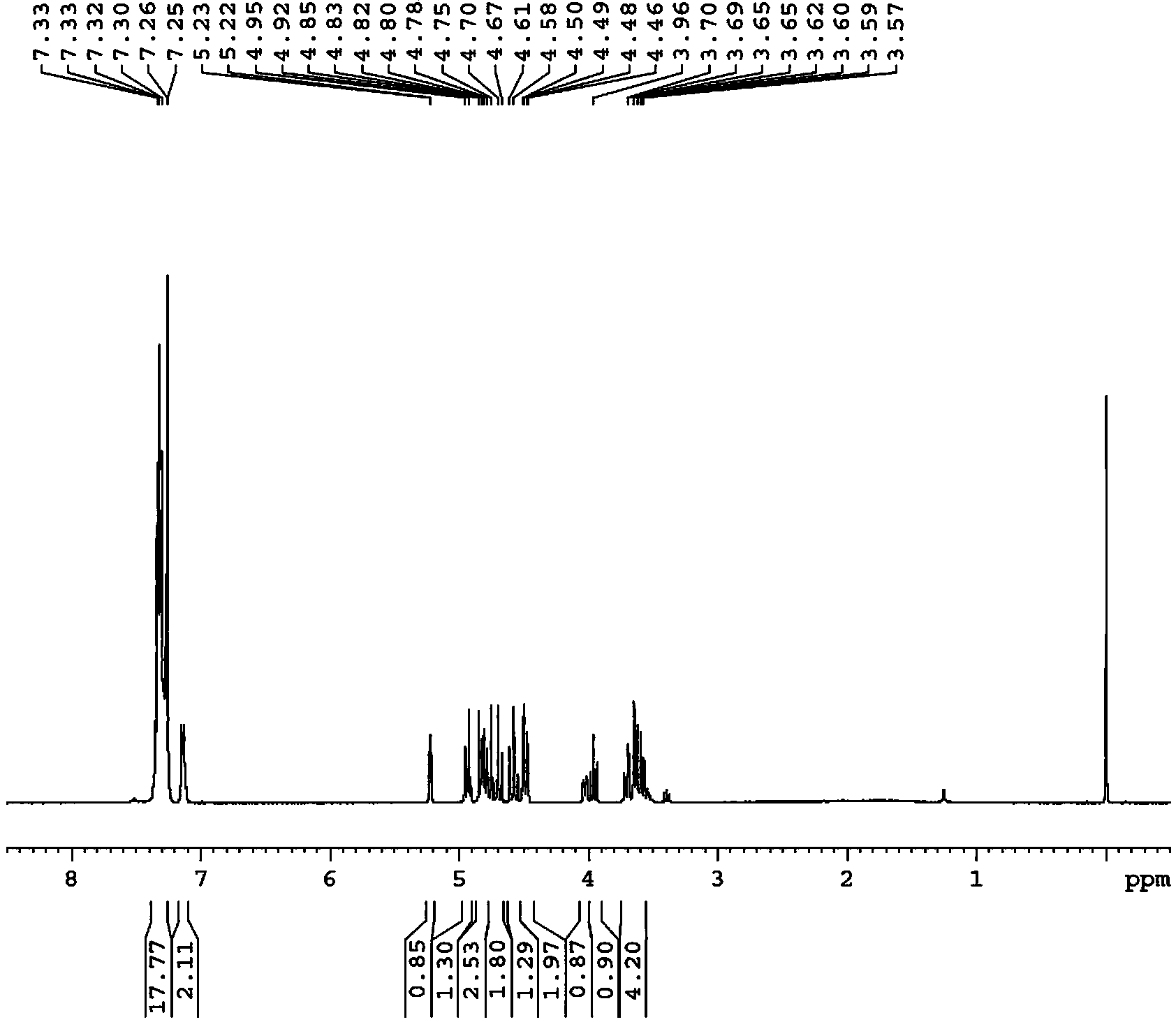

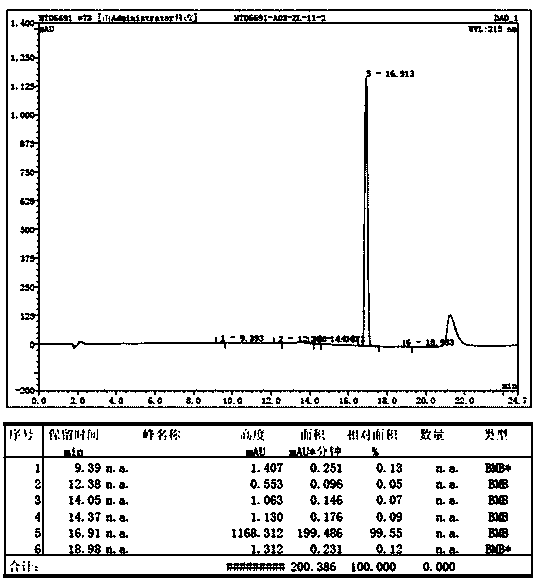

Examples

Embodiment 1

[0038] 1) Weigh 0.1 mol of tetrabenzyl glucoside and 0.5 mol of methanol, and stir until completely mixed;

[0039] 2) Add a catalyst to the above reaction system, carry 0.01 mol of sulfuric acid-hydrofluoric acid on silica gel (based on H content), and react at 100°C for 15 hours;

[0040] 3) Filtrate, wash the filter cake with methanol, combine the filtrate and washings, concentrate under reduced pressure at 40°C to a solid, add 0.3mol of ethyl acetate, dissolve, stir and crystallize at 0°C for 5 hours, and obtain 0.086mol of tetrabenzylglucose with a purity of It was 98.3%, and the yield was 86%.

Embodiment 2

[0042] 1) Weigh 0.1 mol of tetrabenzyl glucoside and 0.8 mol of methanol, and stir until completely mixed;

[0043] 2) Add a catalyst to the above reaction system, carry 0.012mol of sulfuric acid-hydrofluoric acid on silica gel (based on H content), and react at 100°C for 18h;

[0044] 3) Filtrate, wash the filter cake with methanol, combine the filtrate and washings, concentrate under reduced pressure at 40°C to a solid, add 0.3mol of ethyl acetate, dissolve, stir and crystallize at 3°C for 5 hours, and obtain 0.088mol of tetrabenzylglucose with a purity of It was 98.1%, and the yield was 88%.

Embodiment 3

[0046] 1) Weigh 0.1 mol of tetrabenzyl glucoside and 1.0 mol of methanol, and stir until completely mixed;

[0047] 2) Add a catalyst to the above reaction system, 0.015mol of sulfuric acid-hydrofluoric acid supported on silica gel (based on H content), and react at 100°C for 20h;

[0048] 3) Filtrate, wash the filter cake with methanol, combine the filtrate and washings, concentrate under reduced pressure at 40°C to a solid, add 0.3mol of ethyl acetate, dissolve, stir and crystallize at 5°C for 5 hours, and obtain 0.087mol of tetrabenzylglucose with a purity of It was 98.3%, and the yield was 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com