Controllable oxidative-biological degradation plastic master batch and preparation method thereof

A technology of biodegradable plastics and plastic masterbatches, which is applied in the field of manufacturing products containing polymer substances or molding materials, can solve the problems that the degradation rate of mulch film cannot be effectively controlled, the use time will be shortened, and the degradation will not be thorough enough to ensure that the degradation can be achieved controlling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

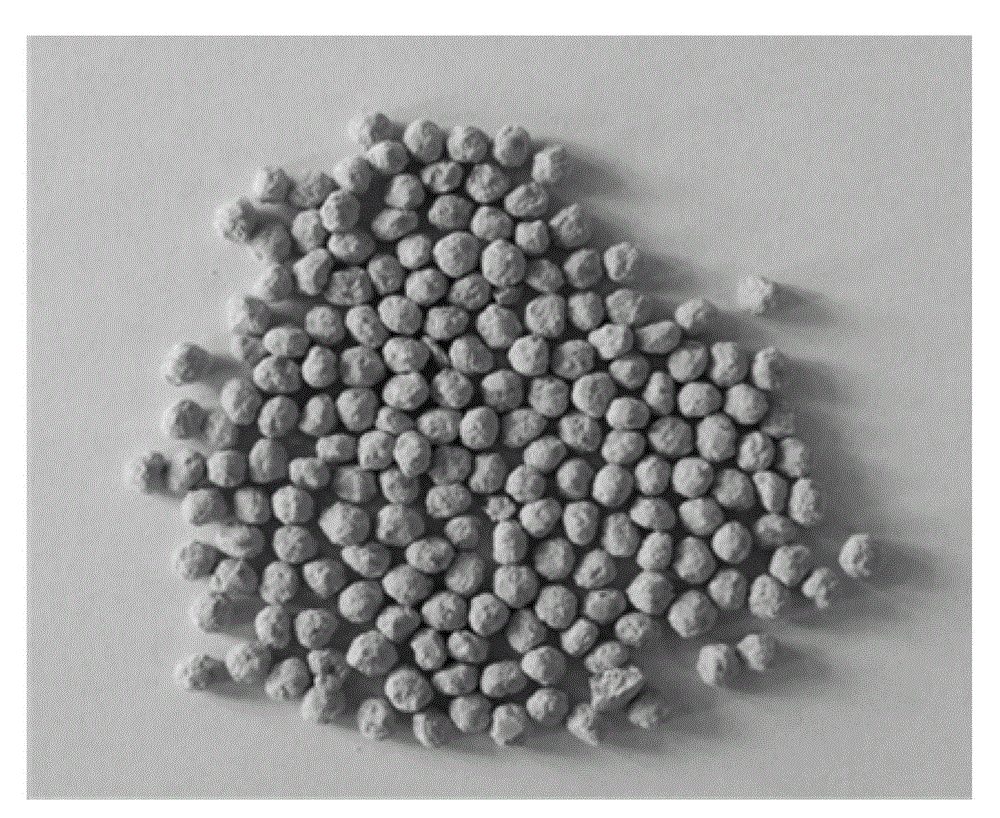

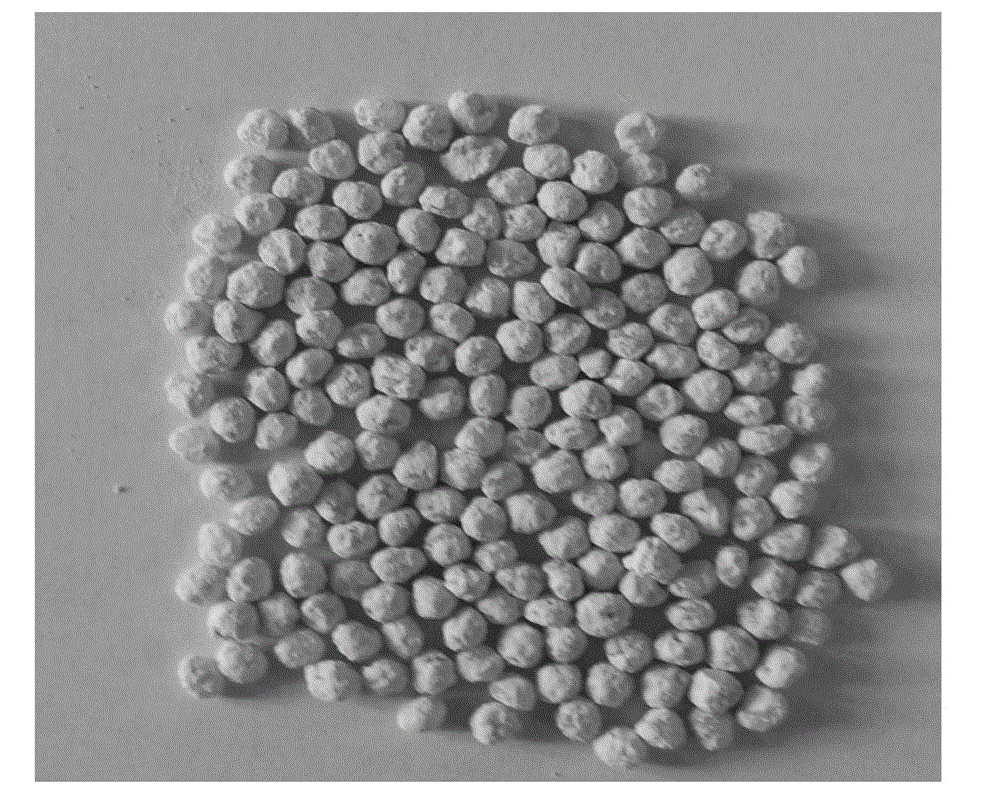

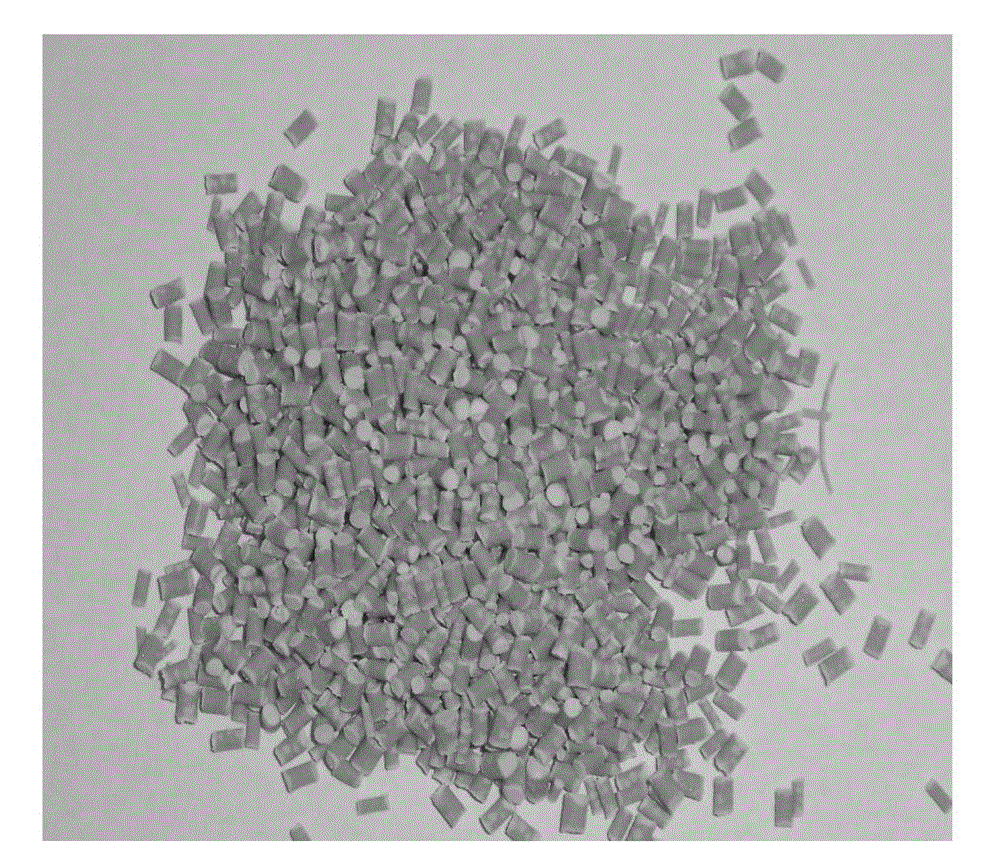

Image

Examples

preparation example Construction

[0104] A preparation method of controllable oxidative biodegradable plastic masterbatch, comprising the steps of:

[0105] (1) Put 40-70 parts of inorganic filler powder and 1-70 parts of biodegradation accelerator into a high-speed mixer, control the temperature at 110-140 °C, control the speed at 400-600 rpm, and mix and stir for 10-20 minutes;

[0106] (2) Divide 1 to 5 parts of the modifier into five equal parts, and add them to the high-speed mixer in batches, with an interval of 3 minutes; the temperature is controlled at 100-130 °C, the speed is controlled at 600-800 rpm, and the mixing is carried out for 18-20 minutes;

[0107] (3) Add 1-10 parts of oxidative degradation accelerator and 1-2 parts of degradation controller into the high-speed mixer, control the temperature at 100-130°C, control the speed at 600-800rpm, and mix and stir for 5 minutes;

[0108] (4) Add 1-5 parts of dispersant into the high-speed mixer, control the temperature at 100-130°C, control the spe...

Embodiment 1~6

[0115] Table 1 shows the composition of the controllable oxidative biodegradable plastic masterbatch described in Examples 1 to 6 of the present invention:

[0116] The formula composition of controllable oxidative biodegradable plastic masterbatch described in Table 1 embodiment 1~6

[0117]

[0118]

[0119] The preparation method of the controllable oxidative biodegradable plastic masterbatch described in Examples 1-6 comprises the following steps:

[0120] (1) Put the formulated amount of inorganic filler powder and biodegradation accelerator into a high-speed mixer, control the temperature at 110-140°C, control the speed at 400-600rpm, and mix and stir for 10-20 minutes;

[0121] (2) Divide the modified agent in the formula into five equal parts, and add it to the high-speed mixer in batches, with an interval of 3 minutes each time; control the temperature at 100-130°C, control the speed at 600-800rpm, and mix and stir for 18-20 minutes;

[0122] (3) Add the formul...

Embodiment 7

[0129] A preparation method of controllable oxidation biodegradable plastic masterbatch comprises the following steps:

[0130] (1) Put 40 parts of 800-mesh talc powder, 30 parts of methylcellulose and 40 parts of chitosan into a high-speed mixer, control the temperature at 110-140°C, control the speed at 400-600rpm, and mix and stir for 10- 20min;

[0131] (2) Divide 5 parts of titanate coupling agent into five equal parts, and add them to the high-speed mixer in batches, with an interval of 3 minutes each time; control the temperature at 100-130 °C, control the speed at 600-800 rpm, and mix and stir for 18-20 minutes ;

[0132] (3) Add 7 parts of cobalt laurate, 3 parts of ferric chloride, 1 part of anti-aging agent IPPD and 1 part of anti-aging agent DPPD into the high-speed mixer, control the temperature at 100-130 °C, control the speed at 600-800 rpm, and mix and stir for 5 minutes;

[0133] (4) Add 4 parts of magnesium stearate and 1 part of stearic acid into the high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com