High-melt-strength polypropylene blend and preparation method thereof

A high melt strength, polypropylene technology, applied in the field of polypropylene blends and their preparation, can solve the problems of PP degradation and chain scission repair, short active center life, low grafting efficiency, etc., so as to improve the grafting efficiency. , Stabilize free radical lifespan and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

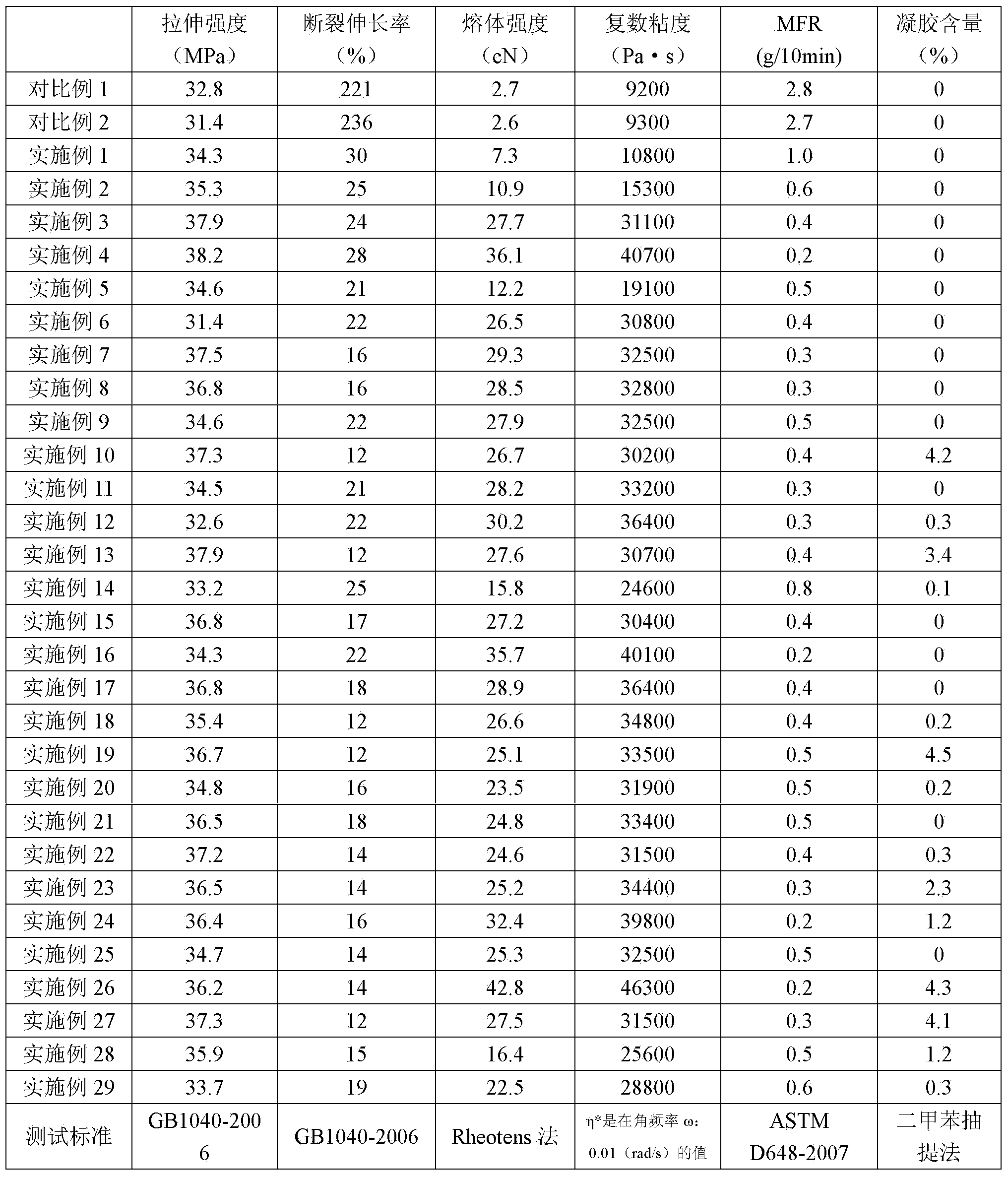

Examples

specific Embodiment approach 1

[0035] Embodiment 1: A high melt strength polypropylene blend of this embodiment is formed by melt blending polypropylene powder, pre-irradiated polypropylene powder, pre-irradiated vulcanized rubber powder, monomer additives and heat stabilizers ;

[0036] The mass ratio of the polypropylene powder to the pre-irradiated polypropylene powder is 100:(1-20); the mass ratio of the polypropylene powder to the pre-irradiated vulcanized rubber powder is 100:(1-20); the The mass ratio of the polypropylene powder to the monomer additive is 100:(0.5-10); the mass ratio of the polypropylene powder to the thermal stabilizer is 100:(0.01-1);

[0037] The described pre-irradiation polypropylene powder is that the polypropylene powder is sealed into a PE bag and subjected to electron beam treatment, wherein the electron beam treatment parameters are: the irradiation dose rate is 10 2 kGy / h~10 3 kGy / h, the irradiation dose is 0.1kGy~100kGy, the irradiation time is 0.001h~0.1h, and the oxyg...

specific Embodiment approach 2

[0039] Embodiment 2: The difference between this embodiment and Embodiment 1 is that: the polypropylene powder is homopolypropylene or copolymerized polypropylene; the stereoregularity of the polypropylene powder is isotactic polypropylene, Syndiotactic polypropylene or atactic polypropylene, the polypropylene powder is in the form of powder, and the weight average molecular weight of the polypropylene powder is 50000g / mol-1500000g / mol. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the rubber latex is polybutadiene rubber latex, styrene-butadiene rubber latex, carboxylated styrene-butadiene rubber latex, nitrile rubber latex, carboxylated butadiene rubber latex Nitrile rubber latex, silicone rubber latex, and acrylic rubber latex. Other steps and parameters are the same as those in Embodiment 1 or 2.

[0041] When the rubber latex described in this embodiment is a mixture, each component is mixed in any ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com