Polymer-modified asphalt waterproof coating

A kind of asphalt waterproof coating and high polymer modification technology, applied in the direction of coating, etc., can solve the problems of secondary pollution, low tensile strength and elongation at break, and achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

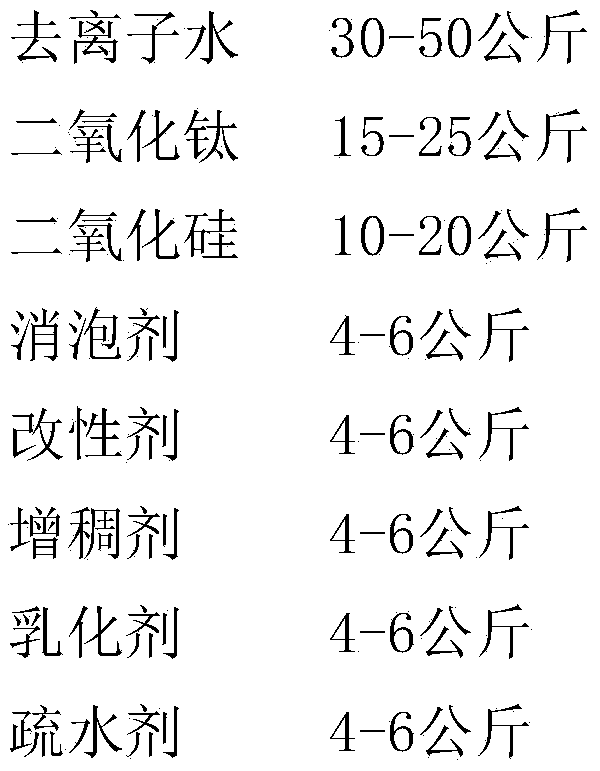

[0014] A kind of high polymer modified asphalt waterproof coating, is made up of the component of following weight,

[0015]

[0016]

[0017] The modifier is composed of 10 kg of anthracene oil, 5 kg of styrene, 0.01 kg of graphene, 0.1 kg of rare earth oxide, 0.1 kg of short polyester fiber, 0.01 kg of humic acid, 0.02 kg of sodium lignosulfonate and butyl acrylate Ester 1 kg composition. By adding components such as humic acid and rare earth oxides, the modifier has a good modification effect without destroying other material properties.

Embodiment 2

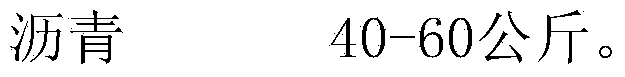

[0019] A kind of high polymer modified asphalt waterproof coating, is made up of the component of following weight,

[0020]

Embodiment 3

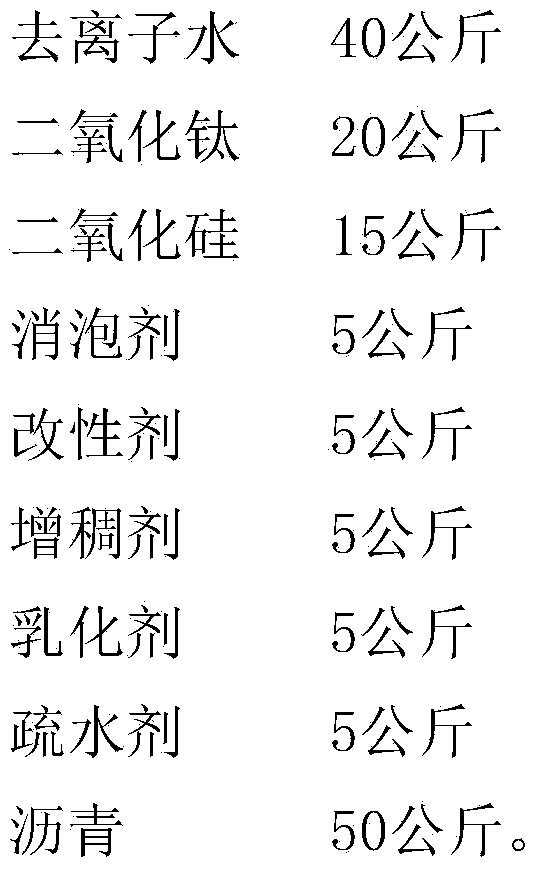

[0022] A kind of high polymer modified asphalt waterproof coating, is made up of the component of following weight,

[0023]

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com