Preparation method and use of oyster bioactive peptides

A technology of active peptides and oysters, applied in diseases, hydrolyzed protein components, fermentation, etc., can solve problems such as ignoring the unique effects of other components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 A kind of preparation method of oyster active peptide

[0016] Take fresh oysters and wash them to obtain fresh oyster meat: add pre-cooled double distilled water according to the ratio of material to water (1:3 (mg: ml), homogenize at high speed for 5 minutes, put it in a refrigerator at 4 ℃ for 1 hr , centrifuged at 8000r / min, 4 ℃ for 30min, took the supernatant, and refrigerated for later use. Take the supernatant and adjust the pH of the solution to 4 with HCL (1:1), centrifuge at 8000r / min for 10min, take the supernatant, adjust the pH to 9 with 5mol / L NaOH, then centrifuge, and adjust the supernatant to neutral with HCL Sex is oyster crude protein. Accurately prepare 5.0% protein suspension with distilled water, first place the oyster enzymatic solution in a 4°C refrigerator for 12 hours, and then centrifuge twice in a high-speed refrigerated centrifuge at 4°C, 7000-8000r / m. Collect the supernatant. Use a high-speed disperser to homogenize for 10 mi...

Embodiment 2

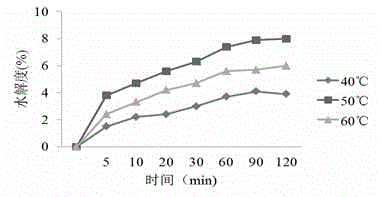

[0017] Example 2 Effect of Reaction Temperature on Hydrolysis Degree of Crude Oyster Egg White

[0018] The pH of the reaction system is controlled at 8.5, the amount of enzyme added is 40AU / kg, the reaction time is 2 hours, and the reaction temperature is 40°C, 50°C, and 60°C for enzymatic hydrolysis. Enzymatic hydrolysis process of oyster homogenate protein at different temperatures see figure 1 , figure 1 As shown, the progress of the enzymatic hydrolysis reaction at different temperatures was studied, and the degree of hydrolysis DH (%) was calculated and compared. As the temperature rises, the alkali consumption increases, indicating that the degree of enzymatic hydrolysis increases. Considering economics, energy consumption, and high temperature may lead to enzyme inactivation, the reaction temperature is 50°C.

Embodiment 3

[0020] The oyster active peptide (CGE) used in this example is the CGE prepared in Example 1.

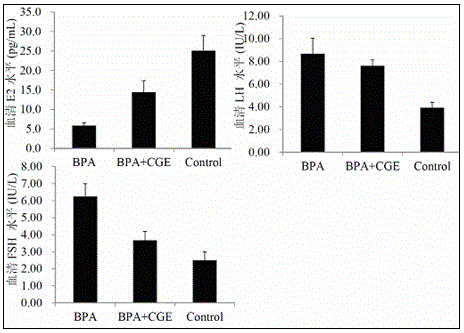

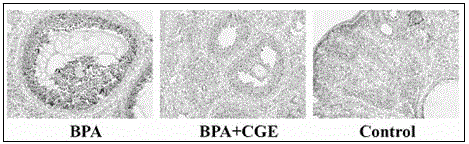

[0021] Select 4-week-old Sprague Dawley (SD) female rats, feed them normally for 12 days, and observe 2 consecutive sexual cycles of 4-5 days through vaginal smears and select them as experimental animals. They were randomly divided into normal control group (Control), model control group (BPA), oyster active peptide+bisphenol A treatment group (CGE+BPA), 6 rats in each group. On the basis of common feed feeding, the Control group was fed with corn oil every day; the BPA group was fed with corn oil containing BPA (fed at 50 mg / kg; BPA was 99% pure) every day; the CGE+BPA group was fed with BPA ( Feed at 50mg / kg; bisphenol A is 99% pure) corn oil plus oyster active peptide and feed at the same time. Rats in each group were fed once a day, weighed every day during treatment, and the dose was adjusted according to body weight. Continuous feeding for 6 weeks. From the 6th day after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com