A valsin wear-resistant coating with high hardness and low coefficient of friction

A low friction coefficient, wear-resistant coating technology, applied in coatings, metal material coating processes, layered products, etc., can solve problems such as cracks, reduce coating wear resistance, and reduce coating hardness, and achieve promotion The effect of mutual diffusion, dense coating and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

[0049] (1) Select M2 stainless steel and Si sheets with a Rockwell hardness of 70 as the substrate of the VAlSiN wear-resistant coating;

[0050] (2) Before deposition, the substrate is pre-cleaned by chemical cleaning and plasma glow;

[0051] (3) Deposition of VAlSiN coating: In the vacuum chamber, the Si target is connected to the cathode of the DC power supply, and the vanadium-aluminum alloy target is connected to the cathode of the intermediate frequency pulse power supply. When the background vacuum is better than 2×10 -4 Pa, after the substrate temperature is maintained at 500°C, Ar gas and N 2 gas, and adjust the working pressure to 0.5Pa, and then adjust the deposition parameters as shown in Table 1, and perform reactive sputtering on the two targets to obtain the VAlSiN wear-resistant coating.

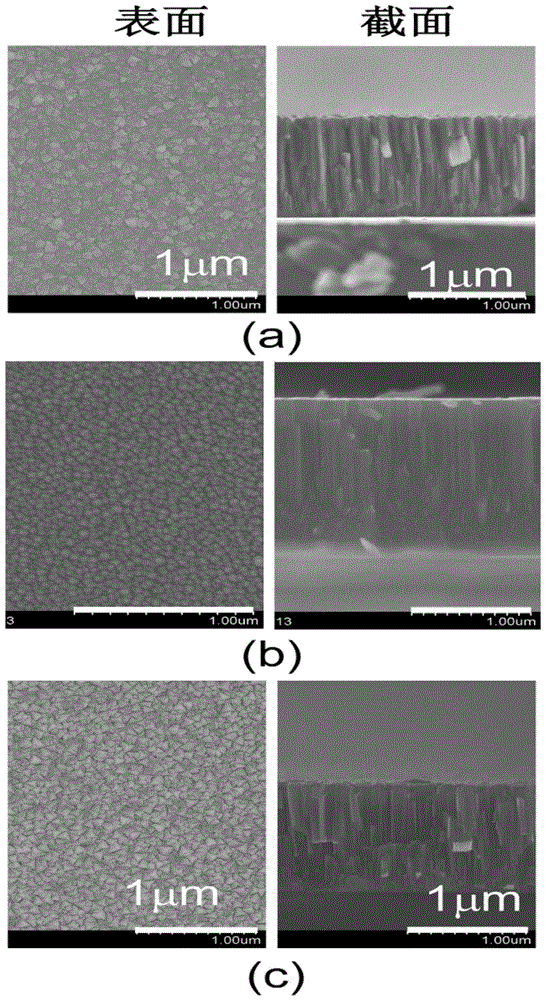

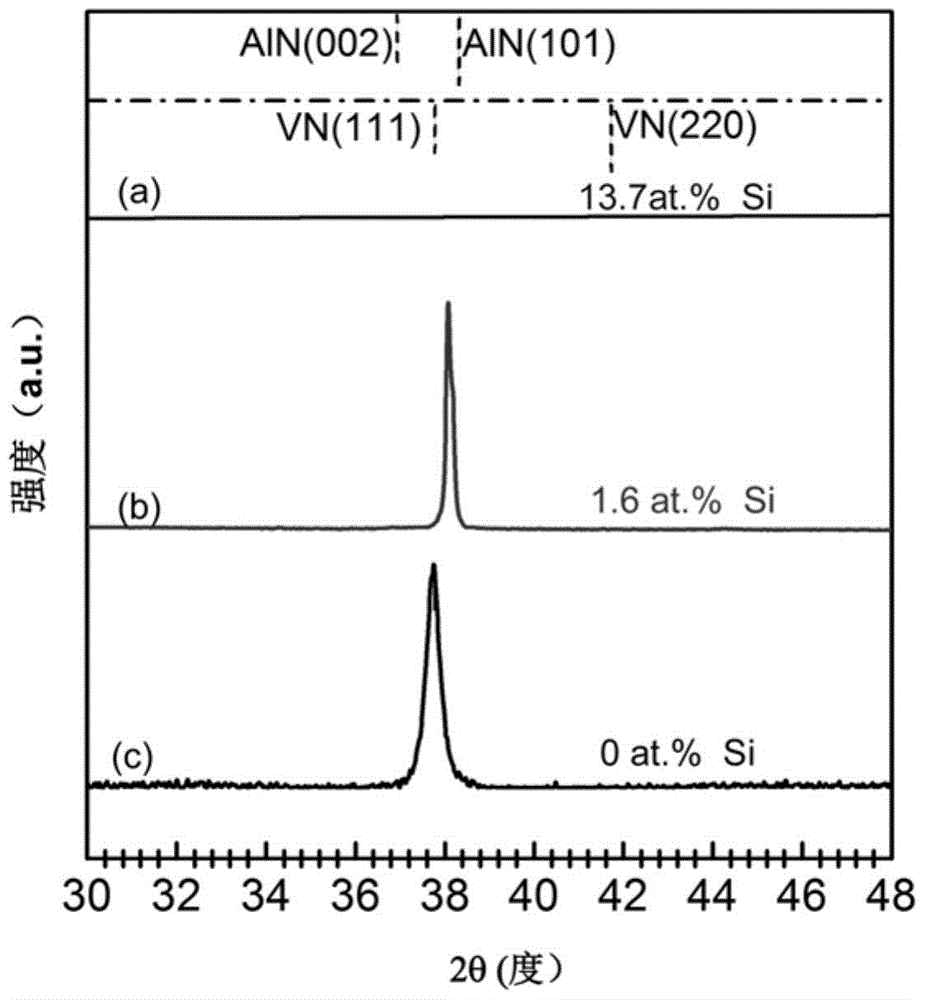

[0052] figure 1 (b) The SEM image of the VAlSiN wear-resistant coating prepared in Example 2. It can be seen that the particle size of the coating is small, there are no m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com