Jellyfish paraffin section making method

A technology for paraffin sectioning and jellyfish, which is applied in the field of preparation of paraffin sections, can solve the problems of difficult frozen sectioning, short time consumption, and few steps, and achieve the effects of shortening preparation time, reducing deformation, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

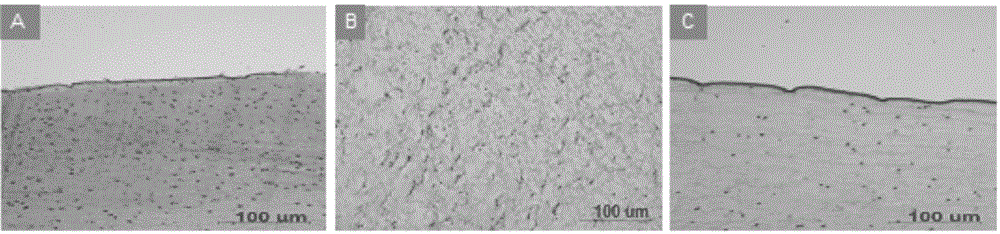

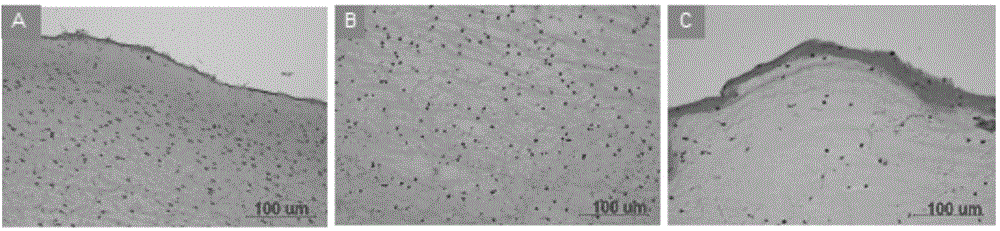

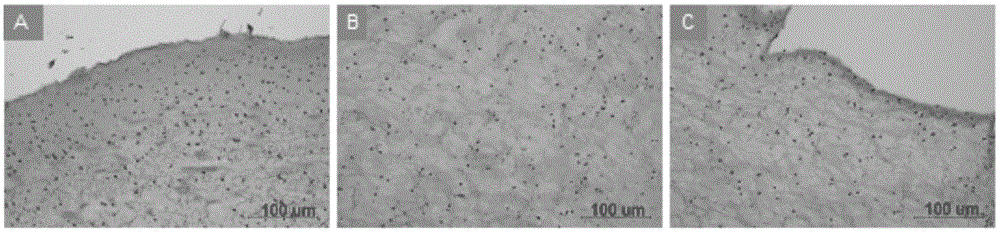

Image

Examples

Embodiment 1

[0061] 1. Material collection and fixation

[0062] Salvage the fresh jellyfish, divide it immediately, wash away the mucus and other impurities on the umbrella body, cut it into 4×4cm tissue pieces, quickly put it in neutral buffered formaldehyde fixative solution at 4°C for 10 hours, take it out and trim it to 0.5×0.5×0.5 cm tissue block, put into the embedding box, alcohol acetate formaldehyde mixed with fixative solution and fixed at 4°C for 12h.

[0063] 2. Dehydration and transparency

[0064] After fixation, the tissue was taken out of the fixative solution, and placed in different concentrations of ethanol and xylene solutions for gradient dehydration and transparency. The specific steps are as follows:

[0065] 80% ethanol 3h→90% ethanol 1.5h→95% ethanol 1h→100% ethanol 45min→100% ethanol 45min→1 / 3 xylene 30min→1 / 2 xylene 40min→full xylene 30min→full xylene 30min.

[0066] 3. Wax penetration and embedding:

[0067] After step 2, the completely dehydrated and transp...

Embodiment 2

[0076] 1. Material collection and fixation

[0077] Take out the salted jellyfish umbrella from the salting pool, wash the salt on the surface of the umbrella body with clean water, cut it into 1.5×4cm strips, fix it in neutral buffered formaldehyde fixative solution at room temperature for 8 hours, take out the trimmed pieces 0.5×0.5×0.5cm and put them in the bag Embed the box, fix with ethanol-acetate-formaldehyde fixative at 4°C for 8h.

[0078] 2. Dehydration and transparency

[0079] After fixation, the tissue was taken out of the fixative solution, and placed in different concentrations of ethanol and xylene solutions for gradient dehydration and transparency. The specific process is as follows:

[0080] 80% ethanol 2h→90% ethanol 1.5h→95% ethanol 1h→100% ethanol 30min→100% ethanol 30min→1 / 3 xylene 30min→1 / 2 xylene 40min→full xylene 30min→full xylene 30min.

[0081] 3. Wax penetration and embedding:

[0082] Put the tissue block treated in step 2 into 1:1 xylene:paraf...

Embodiment 3

[0090] 1. Material collection and fixation

[0091]Cut the salted jellyfish umbrella into 1.5×4cm long strips, the ratio of solid to liquid is 1:10, soak in clean water for 6 hours, change the water every 2 hours, put in neutral buffered formaldehyde fixative solution, fix at room temperature for 8 hours, take out and trim 0.5×0.5 ×0.5cm was put into alcohol-acetic acid-formaldehyde mixed fixative at room temperature and then fixed for 8h.

[0092] 2. Dehydration and transparency

[0093] After fixing the tissue, perform gradient dehydration and transparency, and the specific steps are the same as step 2 of Example 1.

[0094] 3. Wax penetration and embedding:

[0095] The tissue block treated in step 2 was immersed in 1:1 xylene: paraffin for 40 minutes, 58-60°C full paraffin for 30 minutes twice, took out the embedding box, wrapped in newspaper and cooled at 4°C for 30 minutes. Take out the cooled wax block, and embedding normally with LECIA RM2245 embedding machine, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com