Photosensitive Resin Composition And Spacer Preprared From The Same

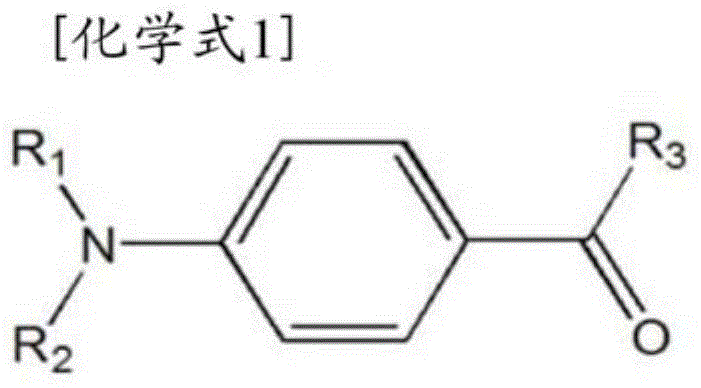

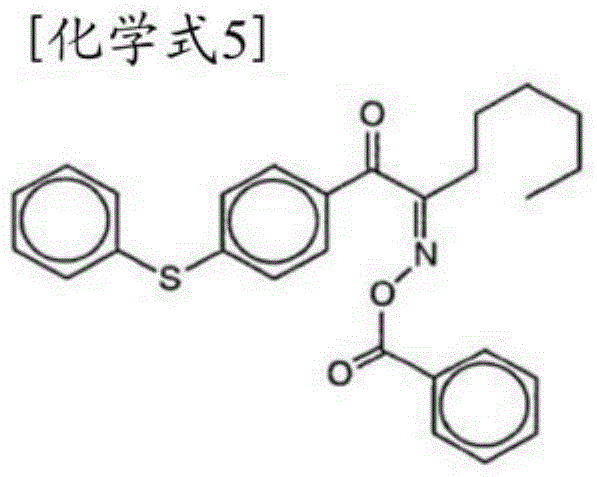

A technology of photosensitive resin and composition, applied in the direction of photosensitive materials, optics, and optomechanical equipment used in optomechanical equipment, can solve the problem of wide size, etc., and achieve excellent adhesion, excellent T/B ratio, transparency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0185] [Synthesis example: Alkali-soluble resin (A-1)]

[0186] In a 1L flask equipped with a reflux condenser, a dropping funnel, and a stirrer, nitrogen was introduced at a flow rate of 0.02 L / min, and 200 parts by mass of 3-methoxy-1-butanol and 105 parts by mass of 3 -Methoxybutyl acetate, heated to 70°C with stirring. Then, it was dissolved in 240 parts by mass of a mixture of the following chemical formula 28 and chemical formula 29 (molar ratio 50:50), 60 parts by mass of methacrylic acid and 140 parts by mass of 3-methoxybutyl acetate to prepare solution.

[0187] 【Chemistry 17】

[0188]

[0189] 【Chemistry 18】

[0190]

[0191] Using a dropping funnel, the prepared solution was dropped into a flask kept at 70° C. over 4 hours. On the other hand, 30 parts by mass of a polymerization initiator 2,2'-azobis(2,4-dimethylvaleronitrile) was dissolved in 225 parts by mass of 3-methoxybutyl acetate to prepare a solution , using another dropping funnel to drop the so...

Embodiment 1~5 and comparative example 1~3

[0205] According to the component and composition described in following Table 1, the photosensitive resin composition (unit is weight part) was prepared. 【Table 1】

[0206]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com