A kind of preparation method of PVDC composition for carbon molecular sieve

A technology of carbon molecular sieve and composition, applied in the field of preparation of PVDC composition, can solve the problems of small apparent density and micropore volume of PVDC composition, unsuitable for PVDC carbon molecular sieve, restricting the application field of PVDC composition, etc. The effect of stable polymerization process, excellent product performance and mild reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] A kind of preparation method of PVDC composition for carbon molecular sieve, comprises the following steps:

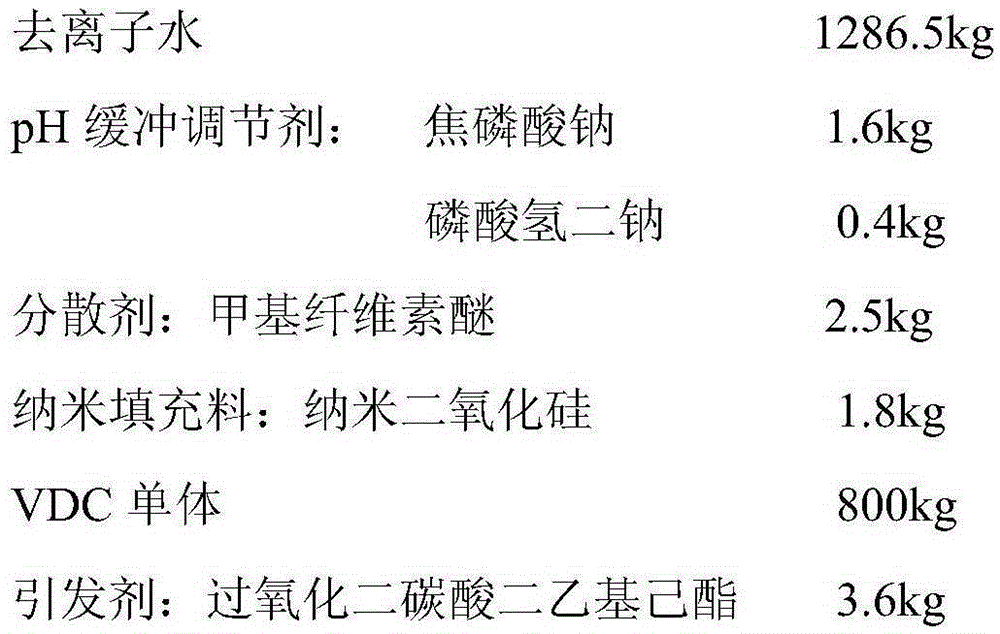

[0040] (1) Prepare the reaction raw materials for subsequent use, and the reaction raw materials consist of:

[0041]

[0042] (2) Preparation of pH buffer regulator aqueous solution and dispersant aqueous solution: Sodium pyrophosphate 1.6kg and disodium hydrogen phosphate 0.4kg, deionized water 20kg are mixed with pH buffer regulator aqueous solution; Methyl cellulose ether 2.5kg, deionized 375kg of ionized water is prepared into aqueous solution of dispersant;

[0043] (3) Preparation of nanofiller aqueous solution: 1.8kg of nano silicon dioxide and 88.2kg of deionized water are prepared into nanofiller aqueous solution;

[0044] (4) Add 257.3kg deionized water and pH buffer regulator aqueous solution to 3M 3 In the polymerization kettle (stainless steel polymerization kettle with stirring device, length-to-diameter ratio of 2:1, three-leaf anchor paddle),...

example 2

[0046] A kind of preparation method of PVDC composition for carbon molecular sieve, comprises the following steps:

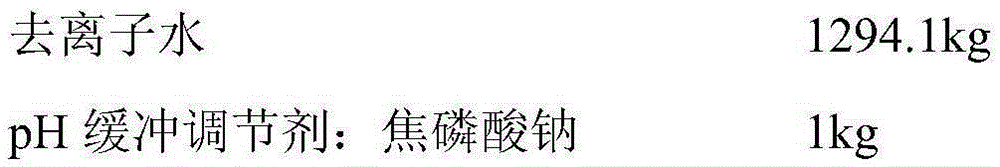

[0047] (1) Prepare the reaction raw materials for subsequent use, and the reaction raw materials consist of:

[0048]

[0049]

[0050] (2) Preparation of pH buffer regulator aqueous solution and dispersant aqueous solution: Sodium pyrophosphate 1kg, deionized water 12.5kg are mixed with pH buffer regulator aqueous solution; Hydroxypropyl methylcellulose 1.9kg, deionized water 285kg are formulated into ingredients Aqueous solution of powder;

[0051] (3) Prepare nanofiller aqueous solution: 1kg nanometer calcium carbonate, 49kg deionized water are mixed with nanofiller aqueous solution;

[0052] (4) Add 129.4kg deionized water and pH buffer regulator aqueous solution to 3M 3 In the polymerization kettle (stainless steel polymerization kettle with stirring device, length-to-diameter ratio of 2:1, three-leaf anchor paddle), the kettle is sealed and replace...

example 3

[0055] A kind of preparation method of PVDC composition for carbon molecular sieve, comprises the following steps:

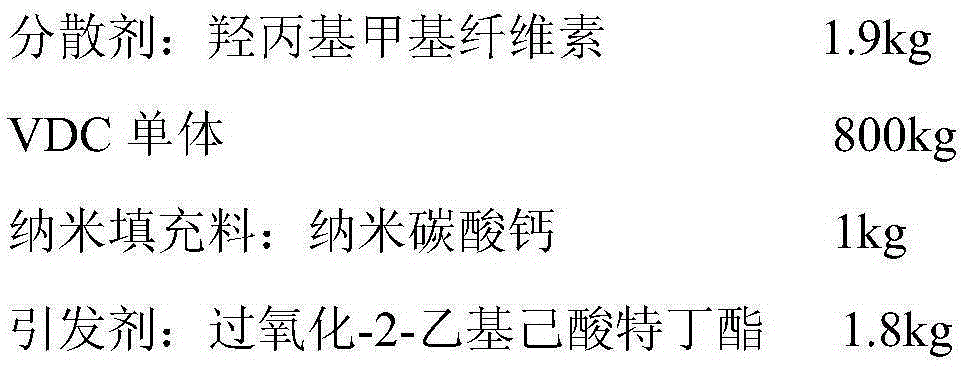

[0056] (1) Prepare the reaction raw materials for subsequent use, and the reaction raw materials consist of:

[0057]

[0058] (2) Prepare pH buffer regulator aqueous solution and dispersant aqueous solution: disodium dihydrogen pyrophosphate 0.6kg, deionized water 7.5kg are mixed with pH buffer regulator aqueous solution; Methyl cellulose 0.8kg, deionized water 134.4kg Prepared as an aqueous solution of dispersant;

[0059] (3) Preparation of nanofiller aqueous solution: 0.4kg nanometer titanium dioxide, 19.6kg deionized water are mixed with nanofiller aqueous solution;

[0060] (4) Add 102.4kg deionized water and pH buffer regulator aqueous solution to 3M 3 In the polymerization kettle (stainless steel polymerization kettle with stirring device, length-to-diameter ratio of 2:1, three-leaf anchor paddle), the kettle is sealed and replaced with nitrogen for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com