Graphene/Cu2AX3 type thermoelectric composite material and preparation method thereof

A composite material, graphene technology, applied in the direction of thermoelectric device junction lead-out material, thermoelectric device manufacturing/processing, etc., can solve problems such as reducing lattice thermal conductivity, achieve easy control of process parameters, good thermoelectric performance, Good prospects for the industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

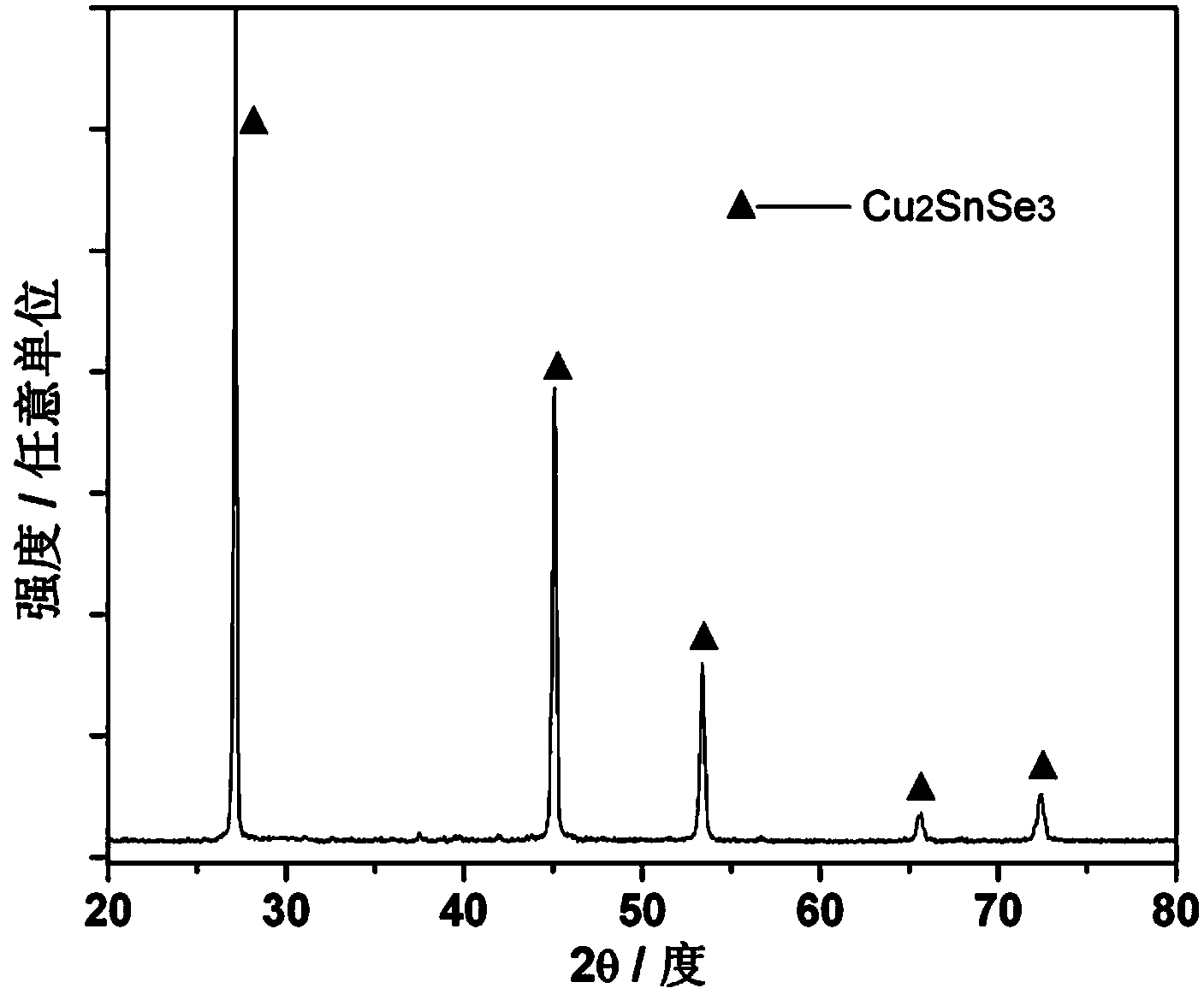

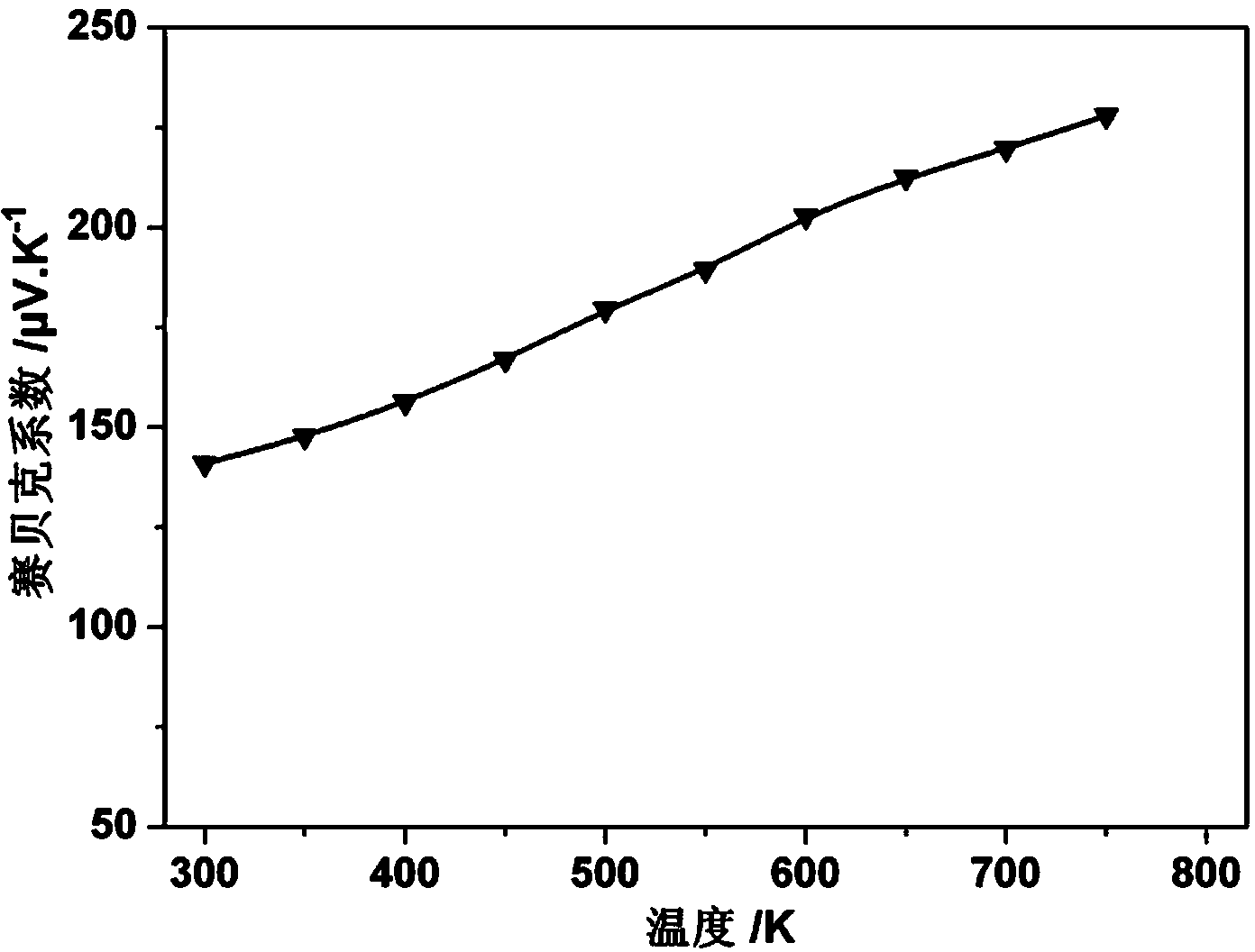

[0035] Use high-purity (99.9%) copper powder (Cu), tin powder (Sn) and selenium powder (Se) as the initial raw materials, and mix according to the stoichiometric ratio of 2:1:3, and weigh a total of about 20g of powder . Then weigh 0.2 g of fullerene, mix it with the above powder, put it into an agate mortar and grind it with alcohol for 30-50 minutes to 400-450 mesh, and dry it in the air. Put the dried powder into a stainless steel ball mill tank, and put 4 kinds of stainless steel balls with different diameters (the ratio of ball to material is 15:1), vacuumize and vent Ar gas in a vacuum glove box, seal it, and then ball mill Put the tank into a planetary ball mill for ball milling, the speed of the ball mill is 400 r / min, and the ball milling time is 48 hours, wherein the star-shaped ball mill is milled in the forward direction for 1 hour, and the stop interval is 15 minutes, and the reverse ball mill is 1 hour, and the stop interval is 15 minutes , reciprocating, the to...

Embodiment 2

[0041] Use high-purity (99.9%) copper powder (Cu), germanium powder (Ge) and selenium powder (Se) as the initial raw materials, and mix according to the stoichiometric ratio of 2:1:3, and weigh a total of about 20g of powder . Then weigh 0.25 g of fullerene, mix it with the above powder, put it into an agate mortar and grind it with alcohol for 30-50 minutes to 400-450 mesh, and dry it in the air. Put the dried powder into a stainless steel ball mill tank, and put 4 kinds of stainless steel balls with different diameters (the ratio of ball to material is 15:1), vacuumize and vent Ar gas in a vacuum glove box, seal it, and then ball mill Put the tank into a planetary ball mill for ball milling, the speed of the ball mill is 400 r / min, and the ball milling time is 48 hours, wherein the star-shaped ball mill is milled in the forward direction for 1 hour, and the stop interval is 15 minutes, and the reverse ball mill is 1 hour, and the stop interval is 15 minutes , reciprocating,...

Embodiment 3

[0045] Use high-purity (99.9%) copper powder (Cu), germanium powder (Ge) and tellurium powder (Te) as the initial raw materials, and mix according to the stoichiometric ratio of 2:1:3, and weigh a total of about 20g of powder . Then weigh 0.15 g of fullerene, mix it with the above powder, put it into an agate mortar and grind it with alcohol for 30-50 minutes to 400-450 mesh, and dry it in the air. Put the dried powder into a stainless steel ball mill tank, and put 4 kinds of stainless steel balls with different diameters (the ratio of ball to material is 15:1), vacuumize and vent Ar gas in a vacuum glove box, seal it, and then ball mill Put the tank into a planetary ball mill for ball milling, the speed of the ball mill is 400 r / min, and the ball milling time is 48 hours, wherein the star-shaped ball mill is milled in the forward direction for 1 hour, and the stop interval is 15 minutes, and the reverse ball mill is 1 hour, and the stop interval is 15 minutes , reciprocating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com