Selective solar energy absorber and manufacturing method thereof used for solar panels, comprises absorber layer containing mixture layer(s) containing high-refractive index dielectric material, and transparent, low-refractive index dielectric layer on substrate

An absorber, solar energy technology, applied in solar thermal power generation, solar thermal devices, coatings, etc., can solve the problems of long-term process offset and difficult process setting, and achieve the effect of easy process adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

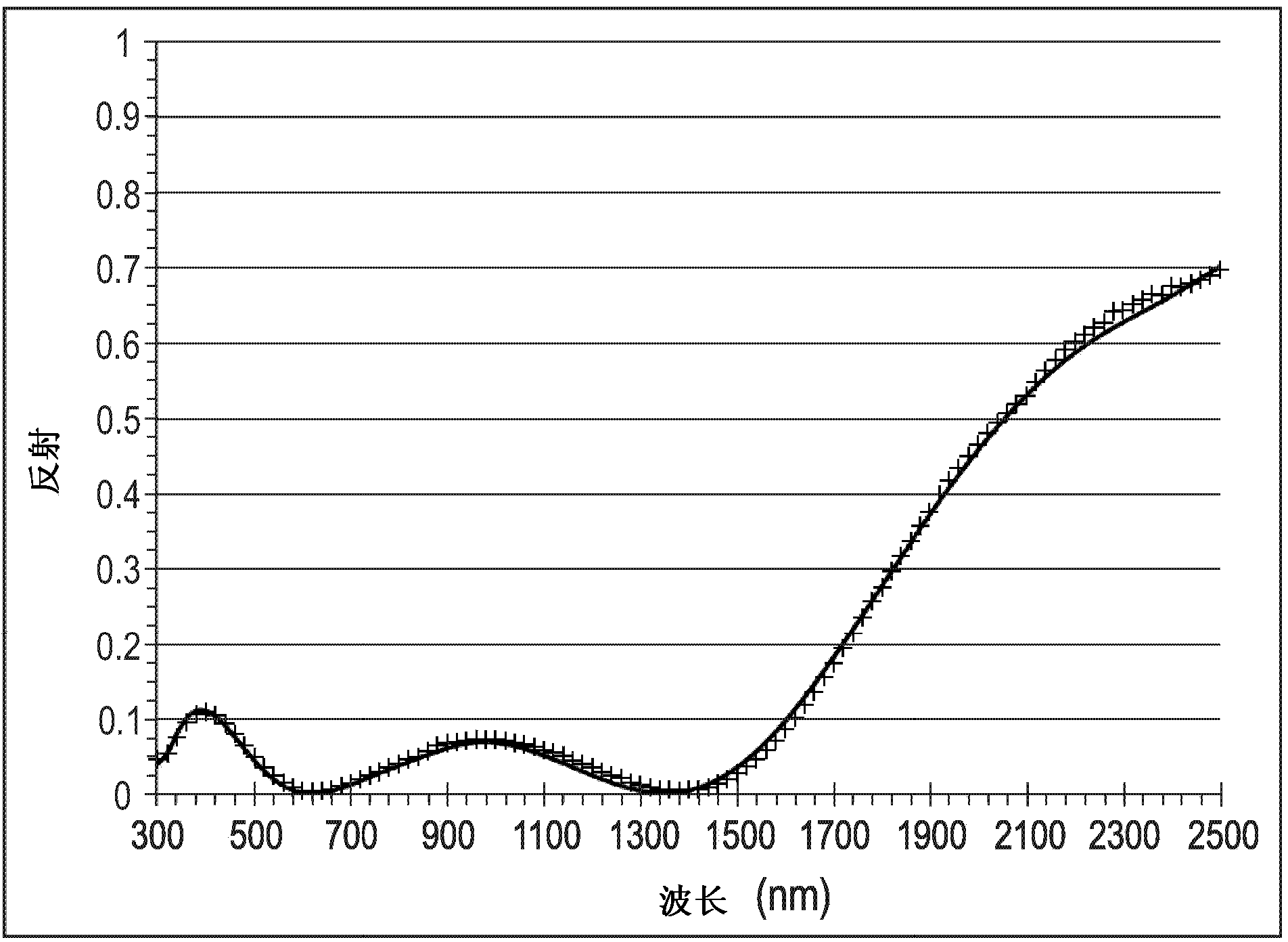

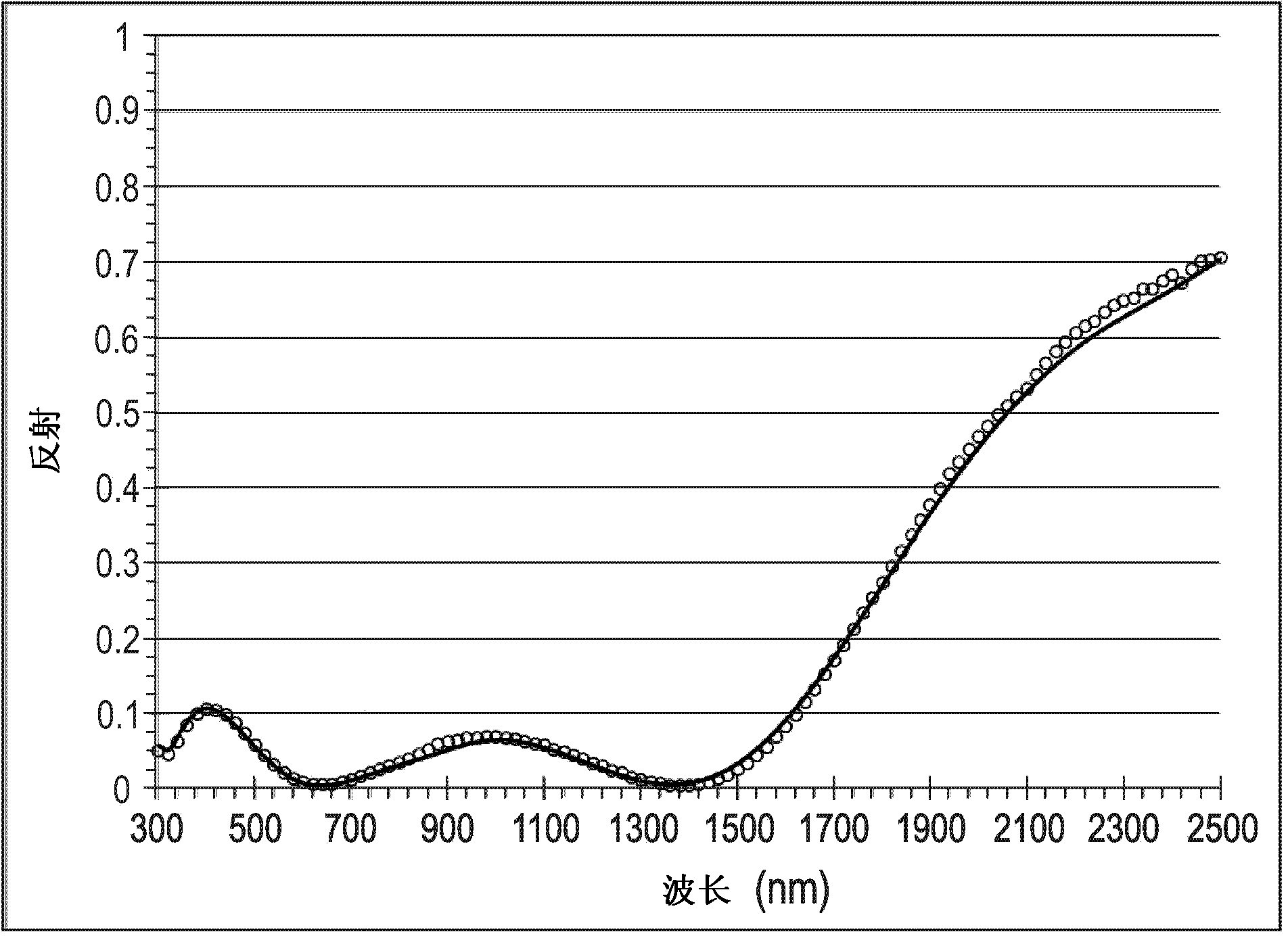

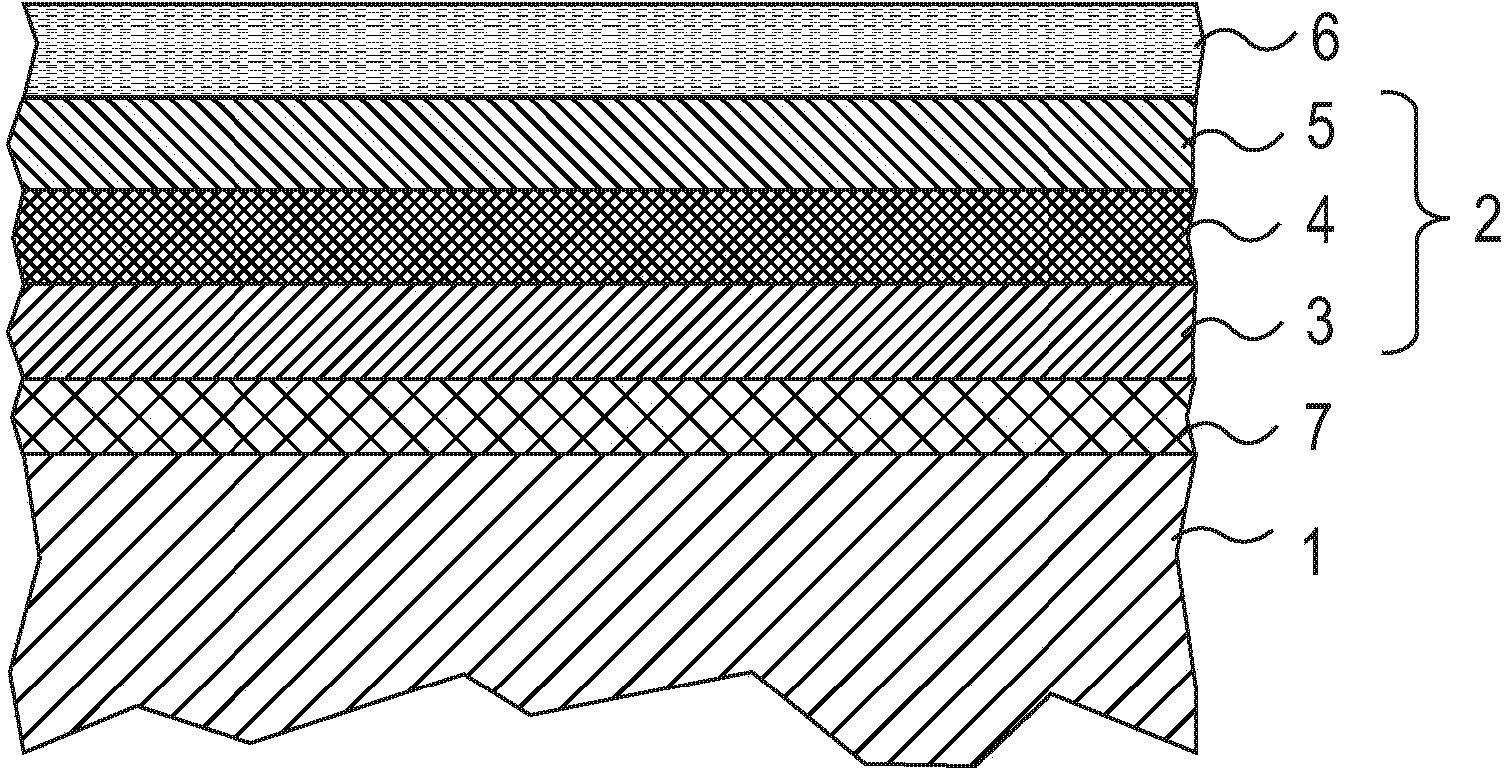

[0049] in accordance with figure 2 In a first example of a solar absorber layer system according to the invention is deposited onto an aluminum substrate 1 .

[0050] An adhesion-increasing layer 7 of aluminum is deposited on the substrate 1 and an absorber layer 2 is deposited on this adhesion-increasing layer, which in this example is constructed in three parts and has a nitrogen An absorbing sublayer 3 of chromium oxide is used as the bottommost sublayer.

[0051] Above the absorbent sublayer 3 is deposited a hybrid layer 4 consisting of the absorbing material of the absorbent sublayer 3 and the transparent material of the dielectric sublayer 5 deposited above the hybrid layer 4, wherein the amount of substance The mixing ratio is 1:1.

[0052] In the sense described above for this material, the dielectric sublayer 5 consists of silicon aluminum nitride. The dielectric sublayer is a layer which is reactively deposited in the presence of nitrogen from a silicon target wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com