High-power multi-core optical fiber laser device

A multi-core fiber, high-power technology, applied to the structure/shape of optical resonators, the structure/shape of active media, etc., can solve the problem of complex coherent combination structure of fiber lasers, inability to guarantee stability, consistency, and high beam Quality and other issues, to achieve high photoelectric conversion efficiency, compact structure, and avoid nonlinear phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

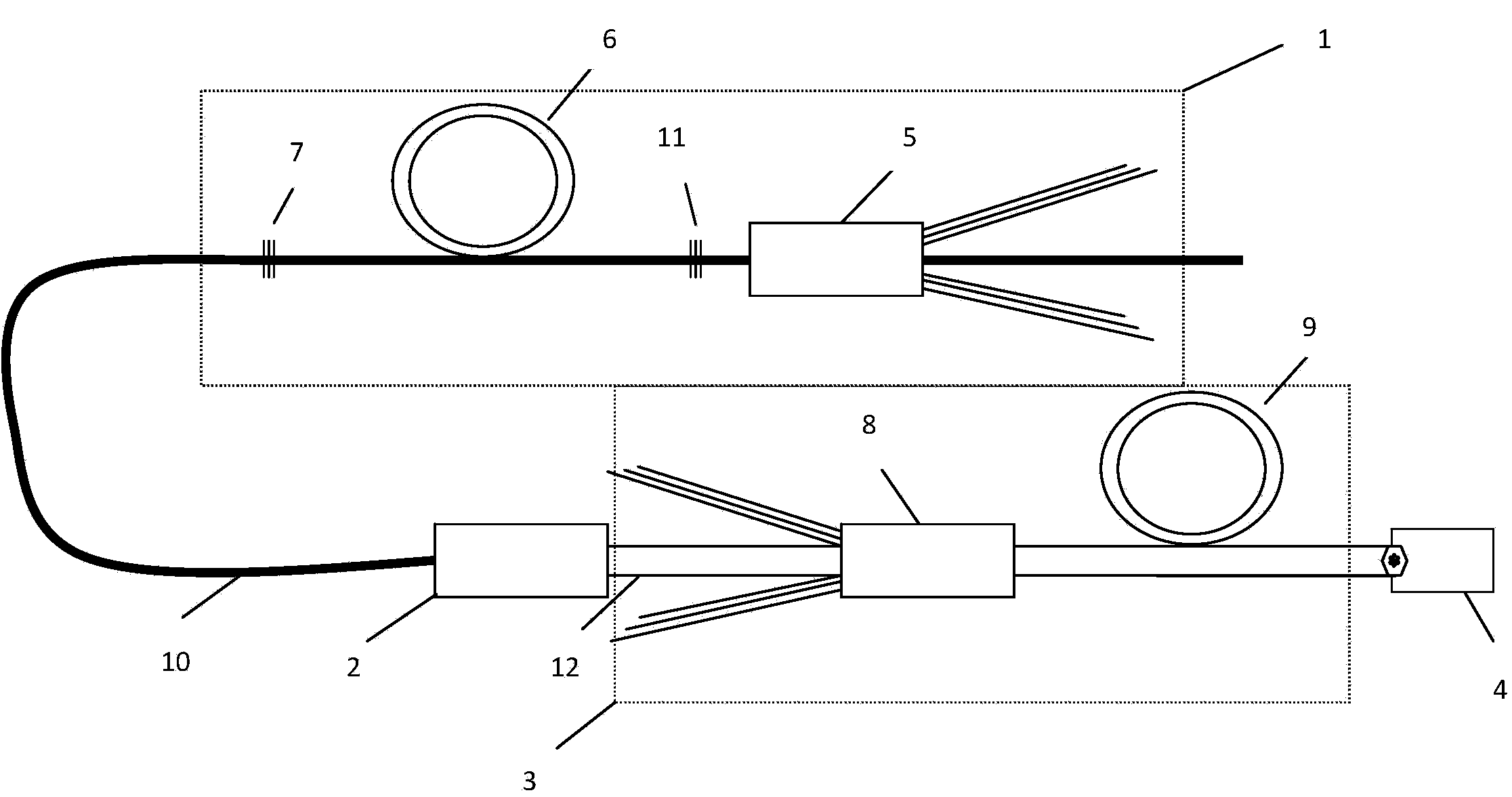

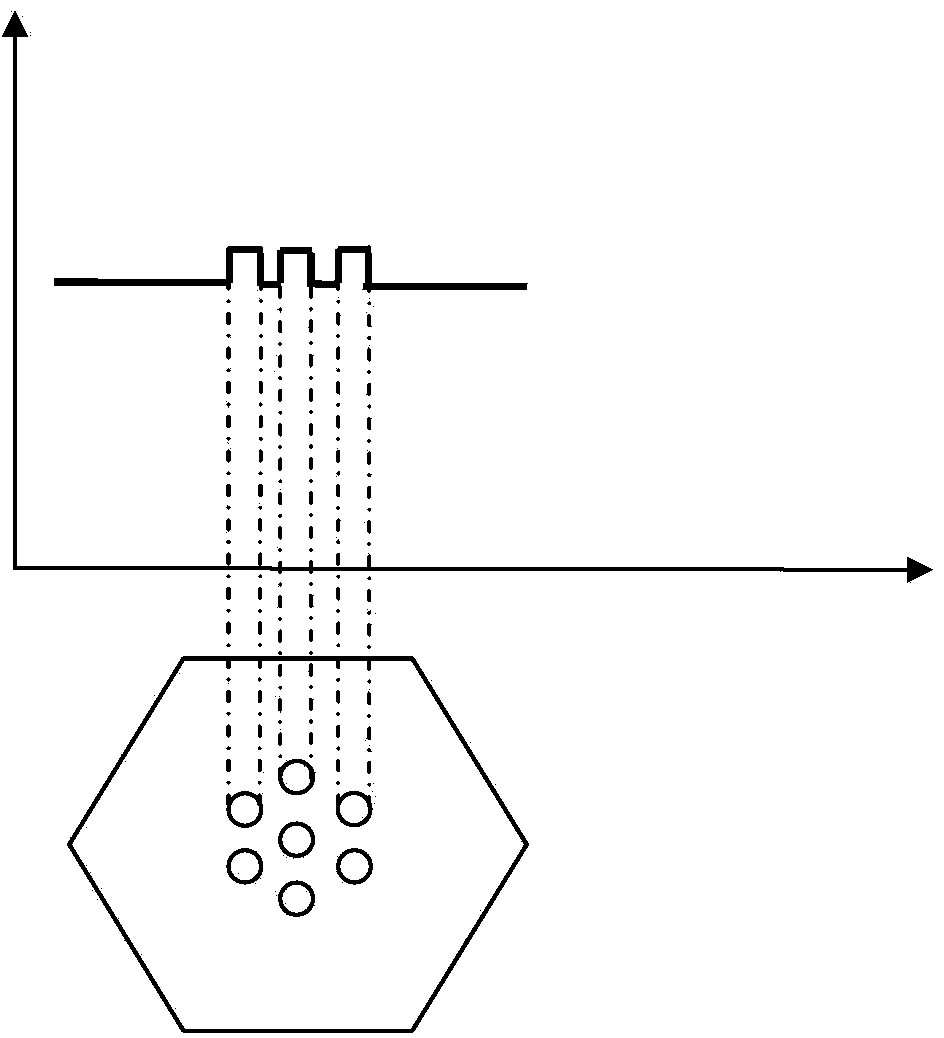

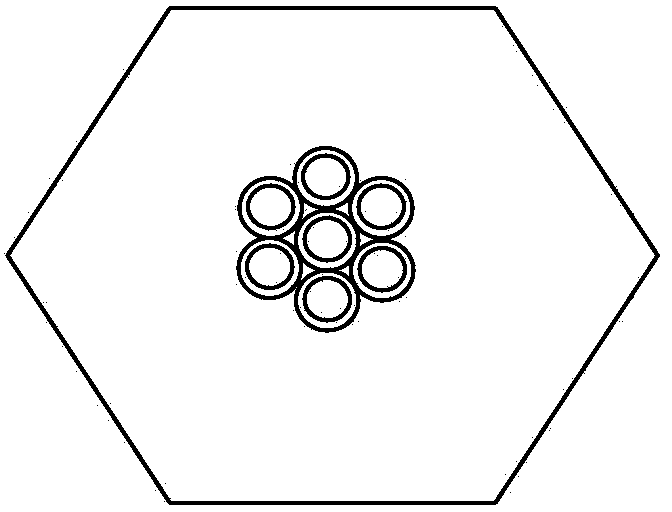

[0025] Such as figure 1 As shown, a high-power multi-core fiber laser is composed of a seed source 1, a mode matcher 2, an amplifier 3, and an optical fiber transmission system. It is characterized in that: the seed source 1 is composed of (N+1)x1 coupler 5 Composed of doped optical fiber 6 and two fiber gratings (7, 11), the output end of (N+1)x1 coupler 5 is connected to a fiber grating 11, doped optical fiber 6, and another fiber grating 7 in sequence, the described Mode matcher 2 is made up of the output fiber 10 of seed source 1 and multicore fiber 12, and described amplifier 3 is made up of multicore (N+1)x1 coupler 8 and multicore doped fiber 9, and mode matcher 2 The multi-core fiber 12 is connected to the input end of the multi-core (N+1)x1 coupler 8, the output end of the multi-core (N+1)x1 coupler 8 is connected to the multi-core doped fiber 9, and the multi-core doped fiber 9 outputs The end cut flat and the end cap 4 are fused to form an optical fiber transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com