Gas desulfurization-denitration-dedusting comprehensive intelligent control system of steel pellet sintering machine

An intelligent control system, desulfurization and denitrification technology, applied in the field of flue gas purification, can solve the problems of incomplete catalytic reaction, imperfect dilution of denitration reactants, and improper temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

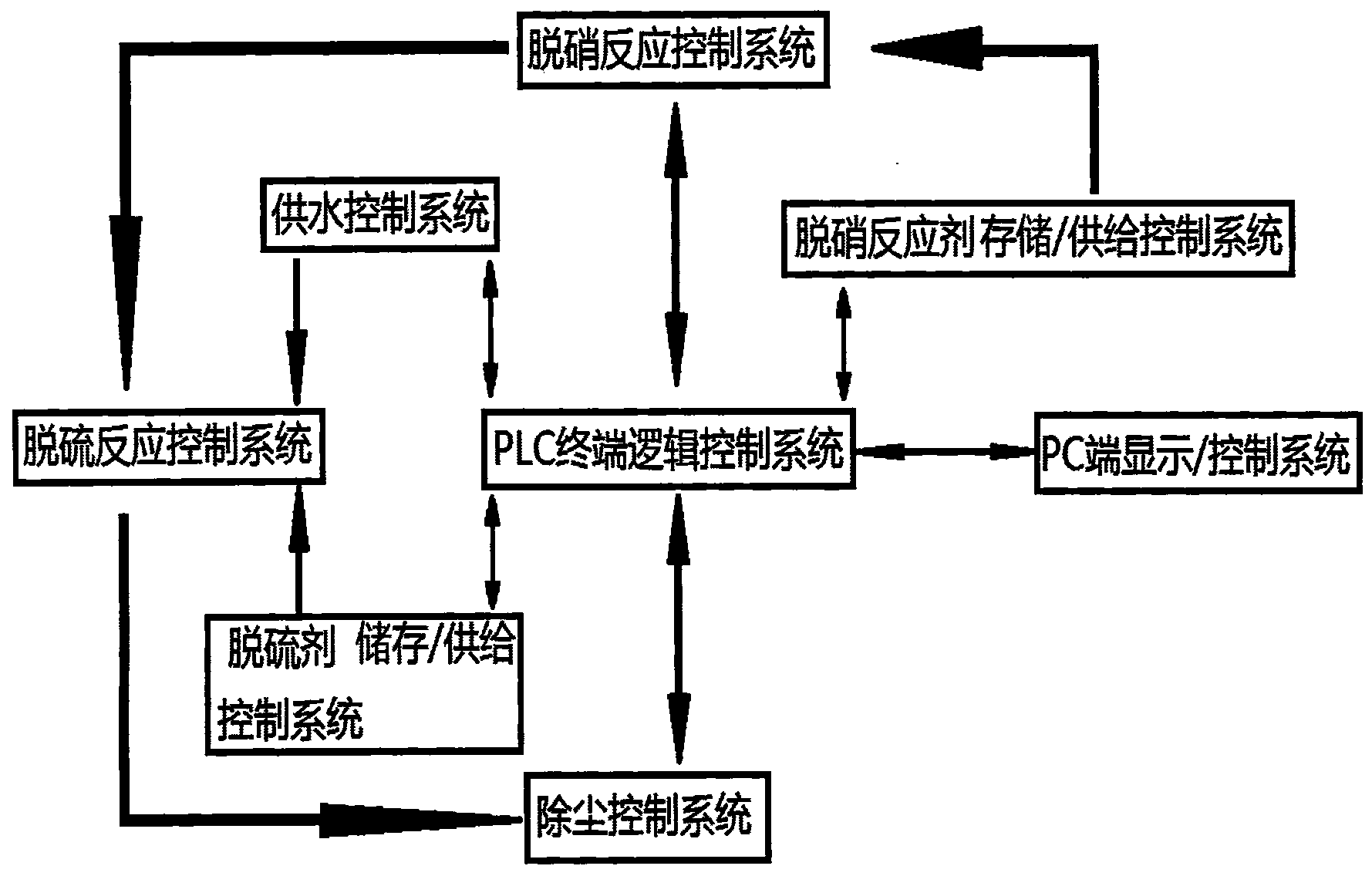

[0039] 1. Denitrification sensory control system

[0040] The flue gas enters the denitrification reactor from the air inlet flue pipe to react, and the PLC terminal control system needs to control it in the whole process, receive, calculate and give feedback. Install a nitrogen oxide monitoring device at the inlet of the flue gas (1) monitor the content of nitrogen oxides in the imported flue gas, and return the monitoring data to the PLC terminal control system. After receiving the relevant data, the system performs preprocessing and directly The quantification is transmitted to the pc display terminal, and the information is notified to the on-site control personnel. At the same time, the PLC system performs calculations, calculates and predicts the value of the nitrogen oxides contained in the flue gas entering the flue gas at this moment and in the next period of time, and needs to adjust the value of the injection content of the denitrification reagent, so that the denit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com