Few-layer boron nitride as well as preparation method and application thereof

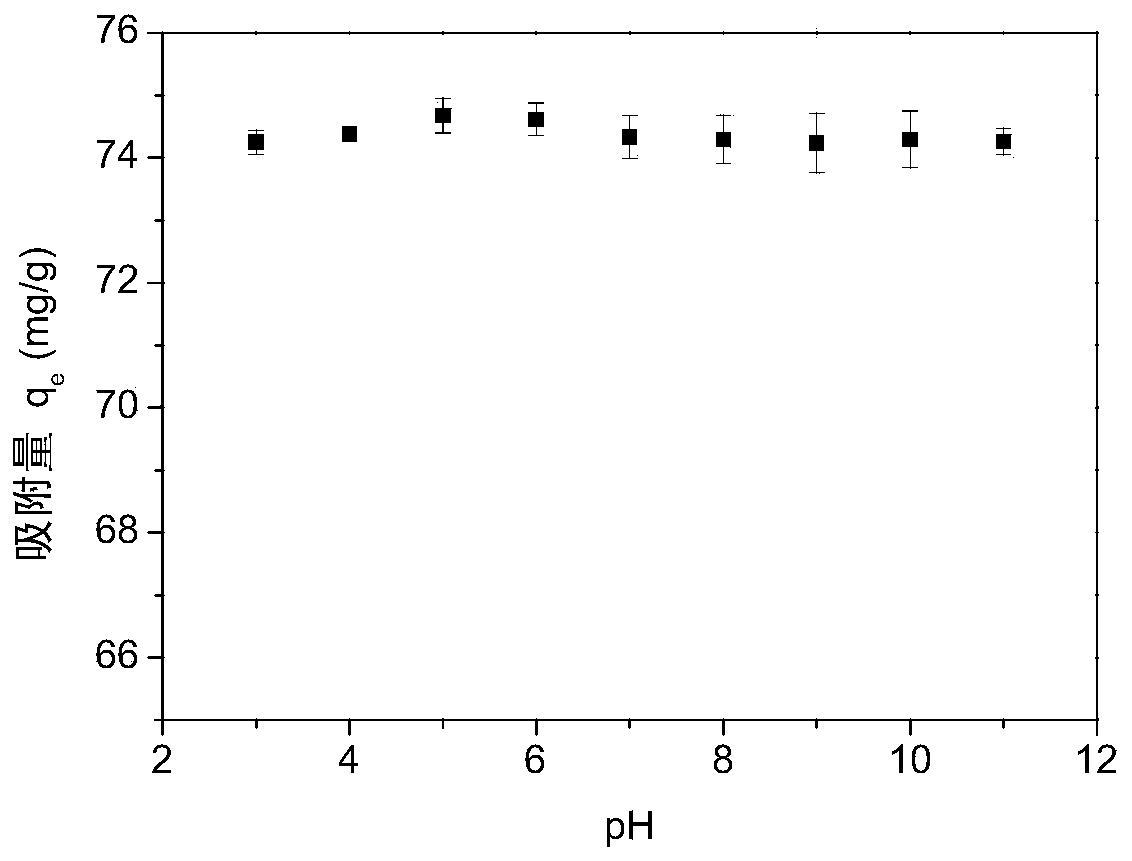

A boron nitride and boron oxide technology, applied in the field of environmental water pollution treatment, to achieve the effects of small impact, no secondary pollution and fast adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

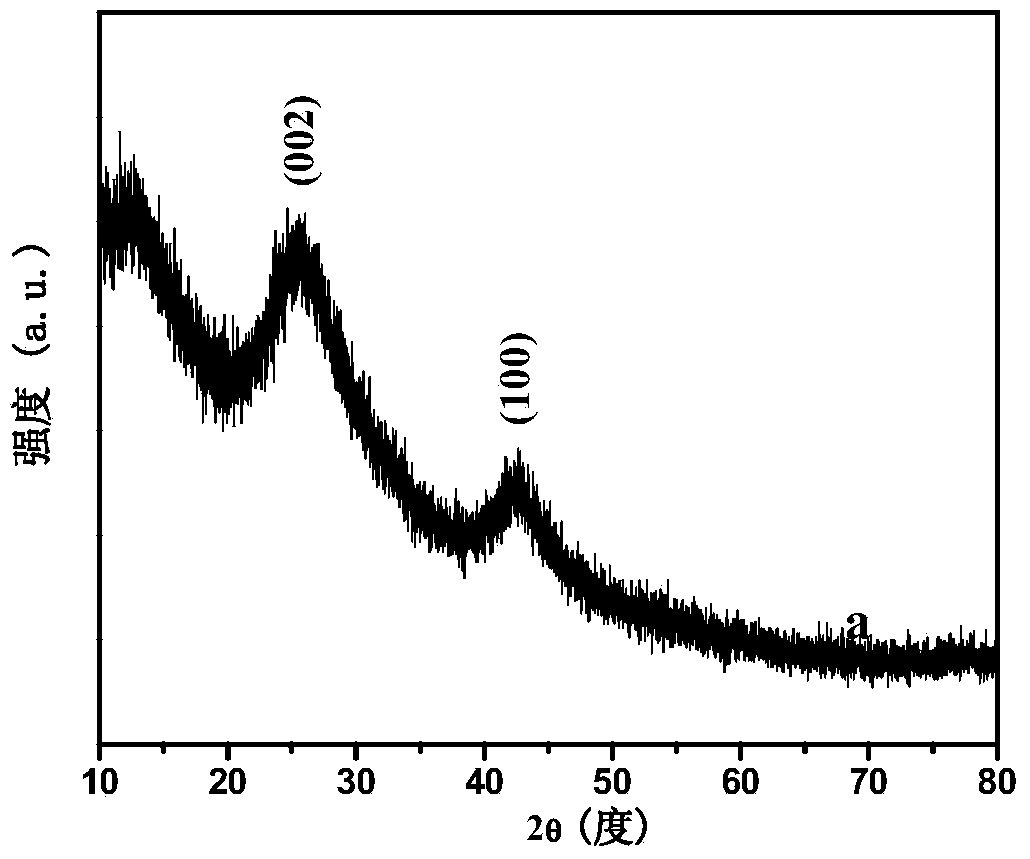

[0030] Weigh and mix urea and boron oxide (molar ratio 1:1), dissolve in 60 mL of 10% ethanol aqueous solution by mass fraction, heat at 50° C., and evaporate to remove the solvent to obtain a white powder. Transfer the white powder mixture to a porcelain boat, use nitrogen as a protective gas in a tube furnace, program the temperature up to 900°C at 1°C / min, keep it for 0.5h for calcination, and obtain a white solid that is few-layer boron nitride.

Embodiment 2

[0032] Weigh and mix urea and boron oxide (molar ratio 1:80), dissolve in 60 mL of 50% ethanol aqueous solution, heat at 50°C, and evaporate to remove the solvent to obtain a white powder. The white powder mixture was transferred to a porcelain boat, and the temperature was programmed to rise to 1100°C at 5°C / min in a tube furnace with nitrogen as a protective gas, and kept for 5h for calcination. The obtained white solid was few-layer boron nitride.

Embodiment 3

[0034] Weigh and mix urea and boron oxide (molar ratio 1:40), dissolve in 60 mL of 30% ethanol aqueous solution, heat at 50°C, and evaporate the solvent to obtain a white powder. Transfer the white powder mixture to a porcelain boat, use nitrogen as a protective gas in a tube furnace, program the temperature up to 900°C at 5°C / min, and keep it for 1h for calcination. The white solid obtained is the few-layer boron nitride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com