Method for preparing silica aerogel photocatalyst formed by compounding nanometer titanium oxide and rare earth solid solution

A technology of nano-titanium oxide and silicon airgel, applied in the field of materials, to achieve strong adsorption capacity, high catalytic performance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

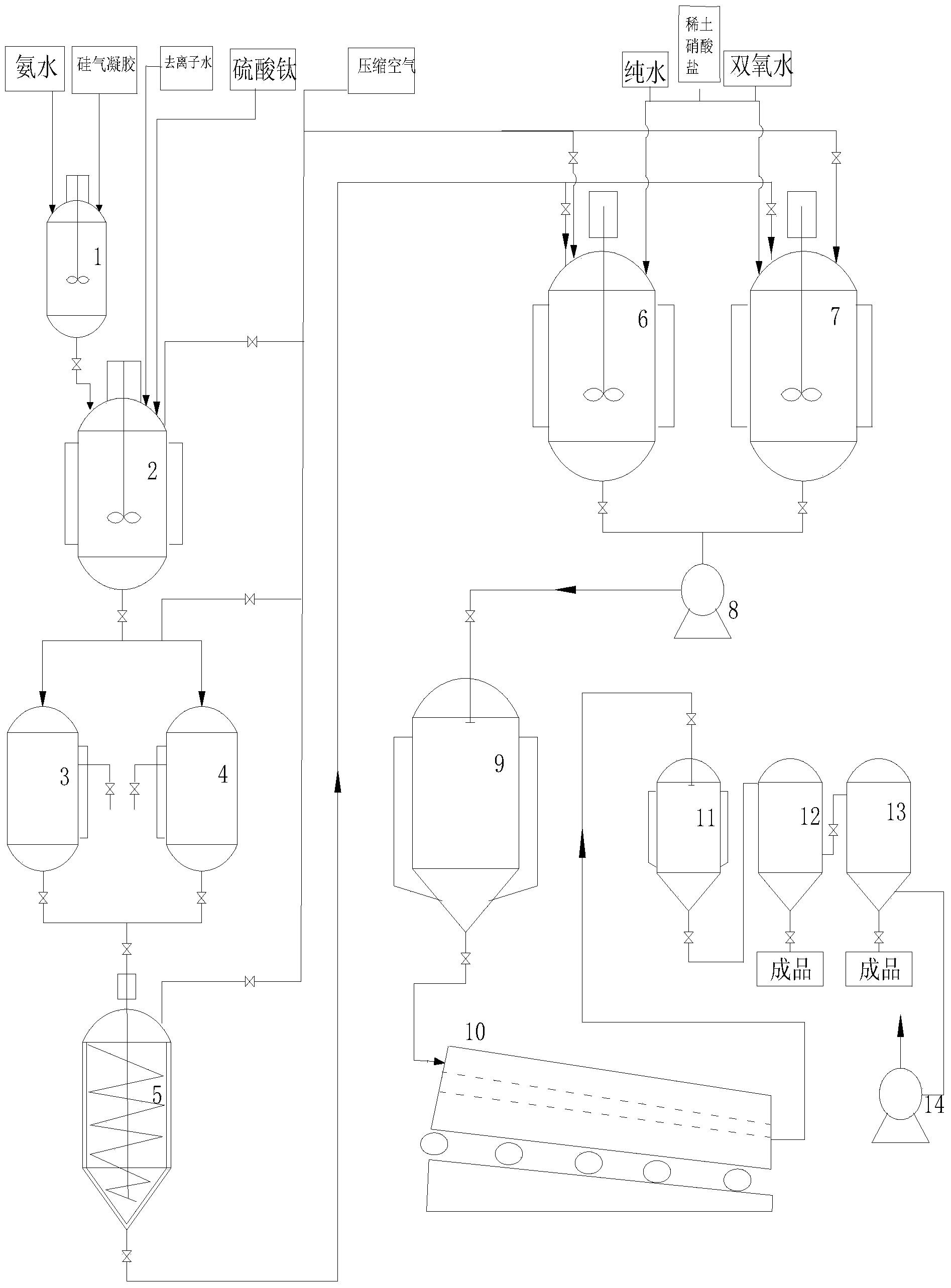

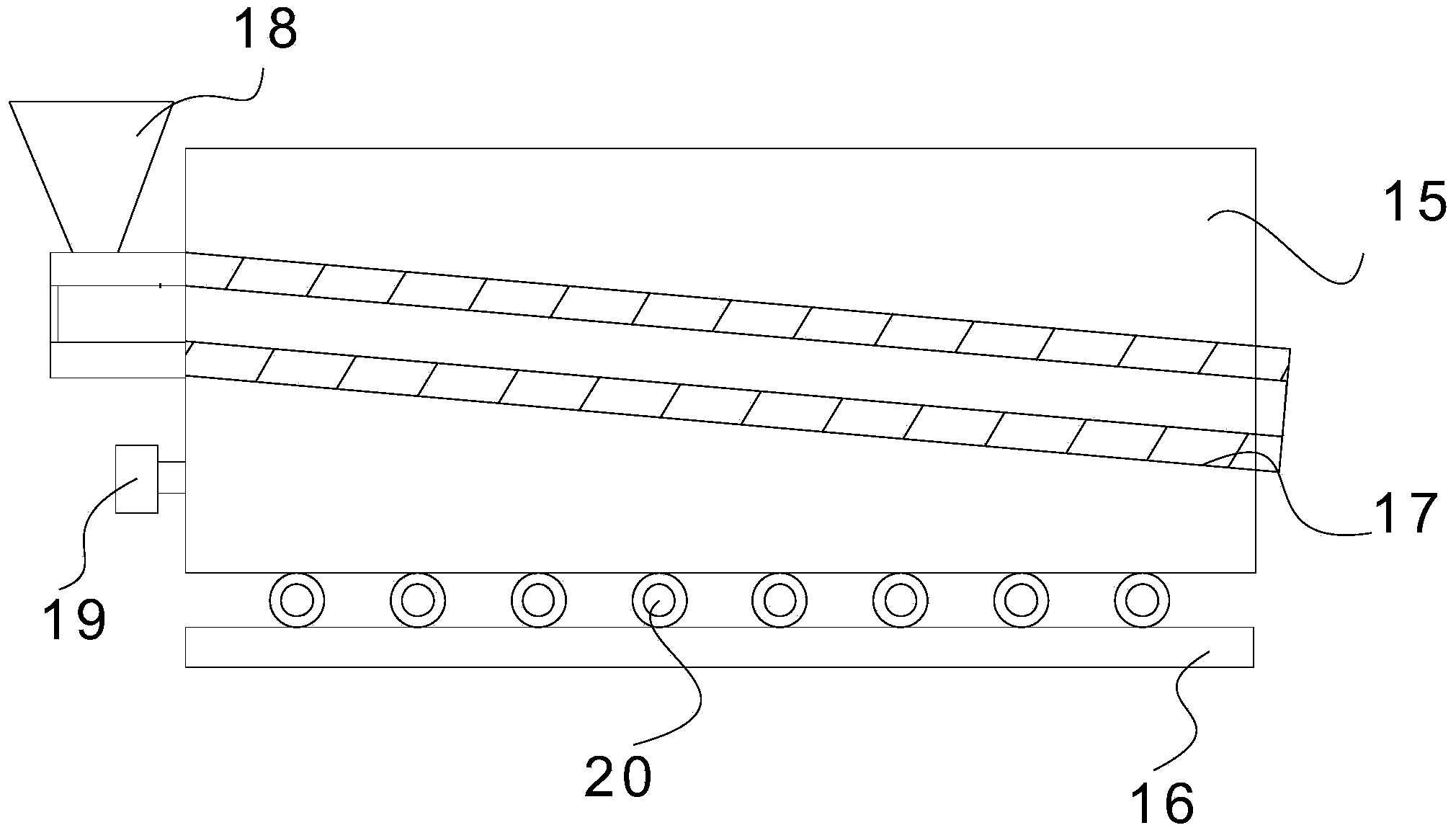

[0029] The invention relates to a method for preparing a silica airgel photocatalyst compounded with nano-titanium oxide and a rare earth solid solution, comprising the following steps:

[0030] (1) Pass the silica airgel particles through a 300-mesh sieve, soak them in 20° ammonia water (the content of liquid ammonia is 20%, and the content of pure water is 80%) for 30-36 hours to obtain material A; mix the rare earth nitrate with 1: 1 The weight ratio is dissolved in deionized water, and the material B is obtained after filtration;

[0031] (2) Since titanium sulfate has different calibration methods and standards when purchasing, in order to more accurately add the amount of titanium sulfate, the amount converted from titanium sulfate to titanium oxide is used as the calibration method; the weight converted from titanium sulfate to titanium oxide The ratio is 5%, and the required titanium sulfate is mixed with deionized water with a weight ratio of 95% to form a solution; t...

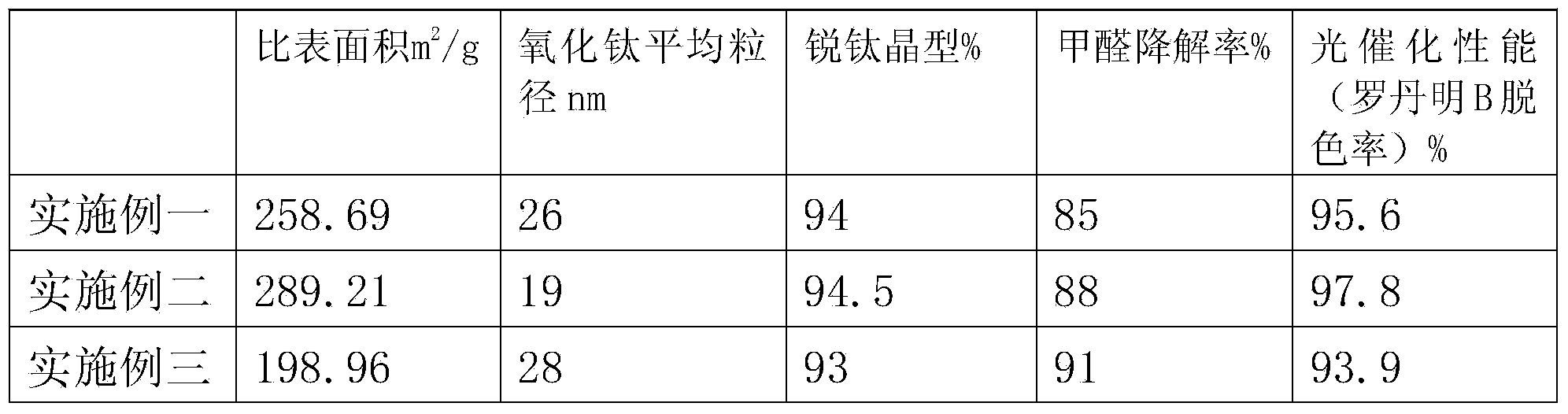

Embodiment 1

[0049] The rare earth nitrate is selected as cerium nitrate, according to Figure 1-Figure 2 The reaction device described in carries out, and preparation method is as follows:

[0050] (1) Silica airgel particles pass through a 300-mesh sieve, soaked in 20° ammonia water (the content of liquid ammonia is 20%, the content of pure water is 80%) for 30 hours, and it is called material A for use, and the cerium nitrate is 1:1 It is more soluble in deionized water, and it is called material B after filtration;

[0051] (2) Heat the mixed solution of titanium sulfate weight ratio 25kg (20% oxide meter) and deionized water 500kg to 75°C while stirring, keep constant temperature, turn on the ultrasonic vibration while the stirring speed is controlled at 580 rpm, The frequency F of ultrasonic vibration is 35KHz, and the power density P is 0.3W / cm 2 , add 4.3 kg of silica airgel (material A) at a uniform speed within 60 minutes, and react for 30 minutes after the addition;

[0052] ...

Embodiment 2

[0056] The rare earth nitrate is selected as lanthanum nitrate, according to Figure 1-Figure 2 The reaction device described in carries out, and preparation method is as follows:

[0057] (1) Silica airgel particles passed through a 300-mesh sieve, soaked in 20° ammonia water for 36 hours, called material A for later use, dissolved lanthanum nitrate in deionized water at a weight ratio of 1:1, and after filtering, called material B for later use;

[0058] (2) Heat the mixed solution of titanium sulfate weight ratio 28kg (titanium dioxide content in titanium sulfate is 20%) and deionized water 500kg to 78°C while stirring, keep constant temperature, and control the stirring speed at 680 rpm Turn on the ultrasonic vibration, the frequency F of the ultrasonic vibration is 35KHz, and the power density P is 0.3W / cm 2 , add 4.3 kg of silica airgel (material A) at a uniform speed within 68 minutes, and react for 20 minutes after the addition;

[0059] (3) Add an appropriate amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com