Preparation method of SiO2-coated core-shell structure catalyst

A core-shell structure and catalyst technology is applied in the field of preparation of Ni/ZrO2SiO2 core-shell structure catalysts, which can solve the problems of difficulty in controlling the particle size of precious metal nanoparticles, complicated preparation process, complicated operation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

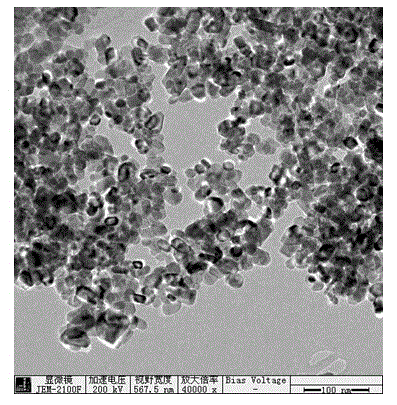

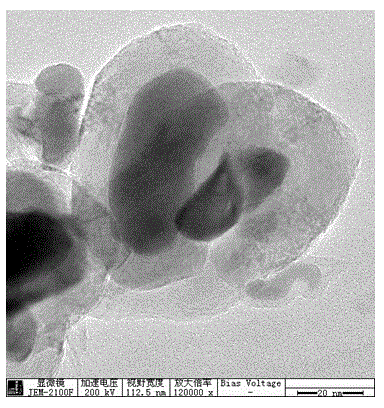

Image

Examples

Embodiment approach 1

[0028] Catalyst preparation: weigh 1.45g Ni(NO 3 ) 2 ·6H 2 O and 2.145g Zr(NO 3 ) 4 ·5H 2 O was added to 40ml deionized water to fully dissolve to obtain a mixed solution; weigh 330mg polyethylene glycol and 1.0g NaOH and dissolve them in 100ml deionized water to obtain a mother liquor; add the mixed solution dropwise to the mother liquor while stirring, and stir at room temperature One hour. The hydrogel was collected by centrifugation, washed with water and alcohol, dried in air at 50°C for 24 hours, and then transferred to a muffle furnace for calcination at 500°C for 2 hours to obtain nanoparticles. Weigh 0.2g of nanoparticles and 1.0g of polyvinylpyrrolidone, disperse them in 100ml of ethanol, stir at room temperature for 12 hours, add 10ml of ammonia water, place in an ultrasonic oscillator for 30 minutes of ultrasonic oscillation, add 0.1ml of tetraethyl orthosilicate and 5ml of ethanol, and ultrasonically shake for 1 hour as needed. The product was collected by ...

Embodiment approach 2

[0035] Catalyst preparation refers to Embodiment 1, the reaction temperature is changed to 650°C and 700°C respectively, and the rest of the conditions are the same. The evaluation results are shown in Table 2.

[0036] Table 2 Ni / ZrO 2 SiO 2 Catalytic performance of catalysts at different reaction temperatures

[0037] Example

Embodiment approach 3

[0039] Catalyst Preparation Referring to Embodiment 1, the Ni / Zr ratios are 1:0.5 and 1:1.5 respectively, and the rest of the conditions are the same. The evaluation conditions refer to Implementation Mode 1, and the evaluation results are shown in Table 3.

[0040] Table 3 Ni / ZrO with different Ni / Zr ratios 2 SiO 2 The effect of catalytic performance

[0041] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com