Preparation method for graphene

A graphene and metal substrate technology, applied in the field of graphene preparation, can solve the problems of graphene performance degradation, graphene sheet structure damage and other problems, and achieve the effects of reducing production energy consumption, low cost and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

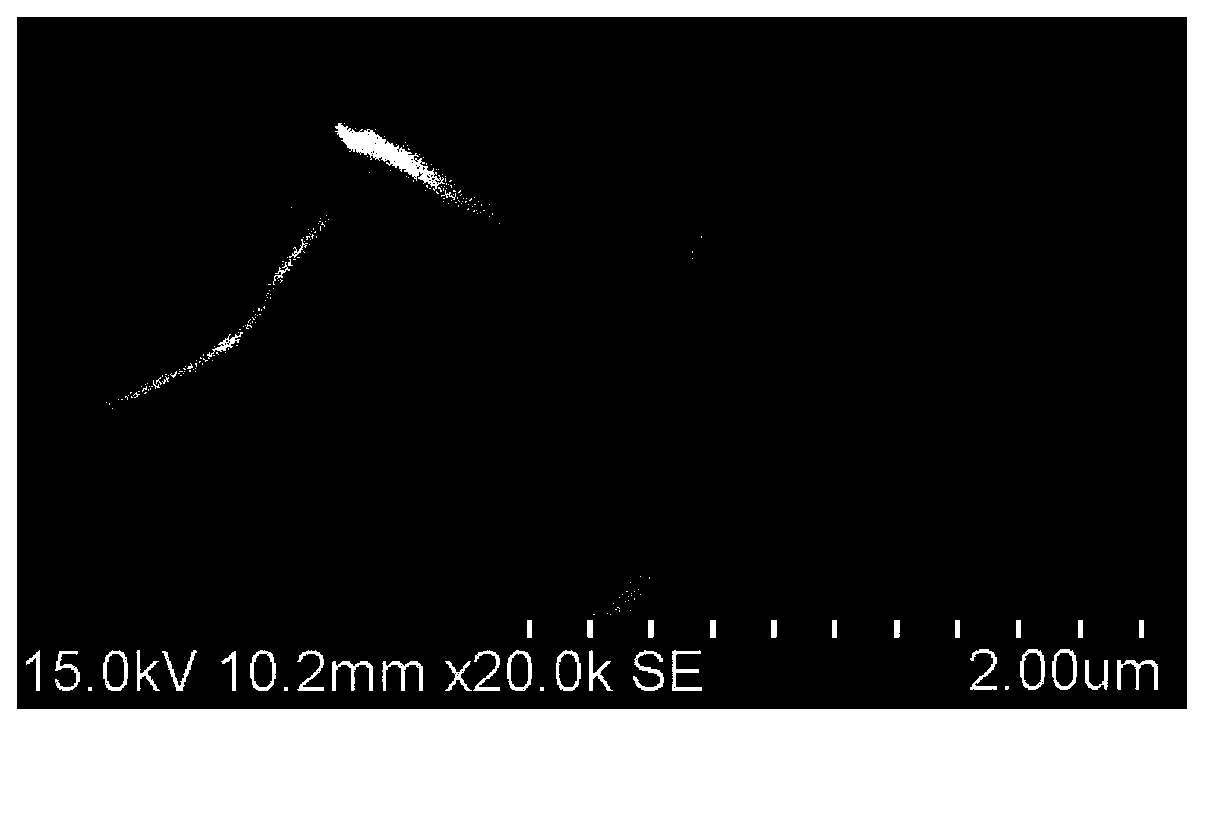

Image

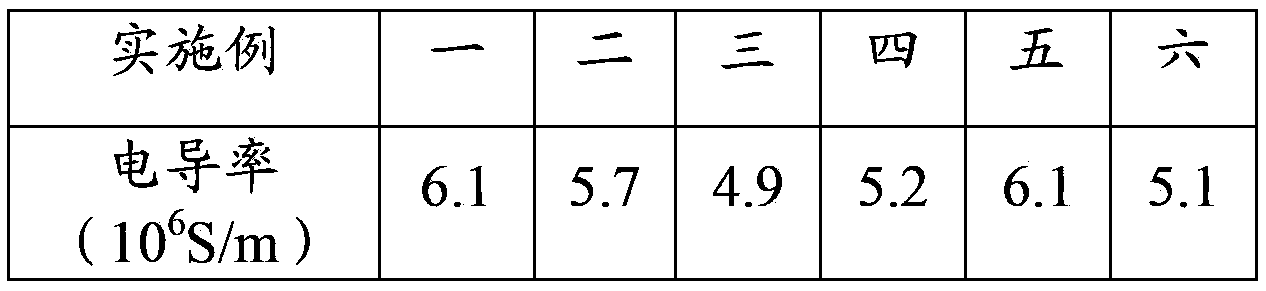

Examples

preparation example Construction

[0024] A kind of preparation method of graphene, comprises the steps:

[0025] (1) Provide the metal substrate, put it into the reaction chamber of the chemical vapor deposition equipment after cleaning, pass the protective gas into the reaction chamber after sealing, stop feeding the protective gas, and vacuumize the reaction chamber to make the reaction chamber in a vacuum state ;

[0026] (2) After heating the metal substrate to 400-500°C, turn on the ultraviolet light source to irradiate the surface of the metal substrate, then pass in the carbon-containing fluid at a flow rate of 50-1000 sccm, keep it warm for 10-100 minutes, and stop the flow after the reaction is completed Stop heating the carbon-containing fluid, turn on the chemical vapor deposition equipment after cooling to room temperature, take out the metal substrate, and obtain a metal substrate with graphene on the surface;

[0027] (3) Soaking the metal substrate with graphene on the surface into the corrosiv...

Embodiment 1

[0039] A kind of preparation method of graphene, comprises the steps:

[0040] (1) Select copper foil as the metal substrate, soak it in acetone solution for 10 minutes and ultrasonically clean it for 10 minutes, then use ethanol and deionized water for 10 minutes, then put the metal substrate into the chemical vapor deposition equipment, seal , feed hydrogen at a flow rate of 20 sccm as a protective gas, and then turn on the pumping system to discharge the air in the reaction chamber; when the working pressure of the reaction chamber reaches 0.1Pa, heat the metal substrate to 500°C.

[0041] (2) Place a 185nm vacuum ultraviolet lamp in the reaction chamber, turn on the ultraviolet lamp to irradiate the surface of the metal substrate, then pass methane at a flow rate of 50 sccm, and keep it warm for 100 minutes. At this time, methane is reduced to carbon atoms under ultraviolet irradiation under high temperature conditions , and grow on the metal substrate, and finally form a ...

Embodiment 2

[0044] A kind of preparation method of graphene, comprises the steps:

[0045] (1) Select iron foil as the metal substrate, soak it in acetone solution and ultrasonically clean it for 30 minutes, then use ethanol and deionized water to ultrasonically clean it for 30 minutes each, then put the metal substrate into the chemical vapor deposition equipment, seal , with a flow rate of 50 sccm into the helium as a protective gas, and then open the pumping system to exhaust the air in the reaction chamber; when the working pressure of the reaction chamber reaches 100Pa, the metal substrate is heated to 400°C.

[0046](2) Place a 150nm vacuum ultraviolet lamp in the reaction chamber, turn on the ultraviolet lamp to irradiate the surface of the metal substrate, and then pass through acetylene at a flow rate of 200 sccm, and keep it warm for 10 minutes. At this time, the acetylene is reduced to carbon atoms under high temperature conditions under ultraviolet irradiation , and grow on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com