Quick-drying primer-topcoat two-in-one steel member paint and preparation method thereof

A quick-drying steel structure technology, applied in coatings, anti-corrosion coatings, rubber derivative coatings, etc., can solve the problems of restricting the production capacity of steel structure factories, increasing labor costs, etc., and achieve the goal of fast drying speed and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

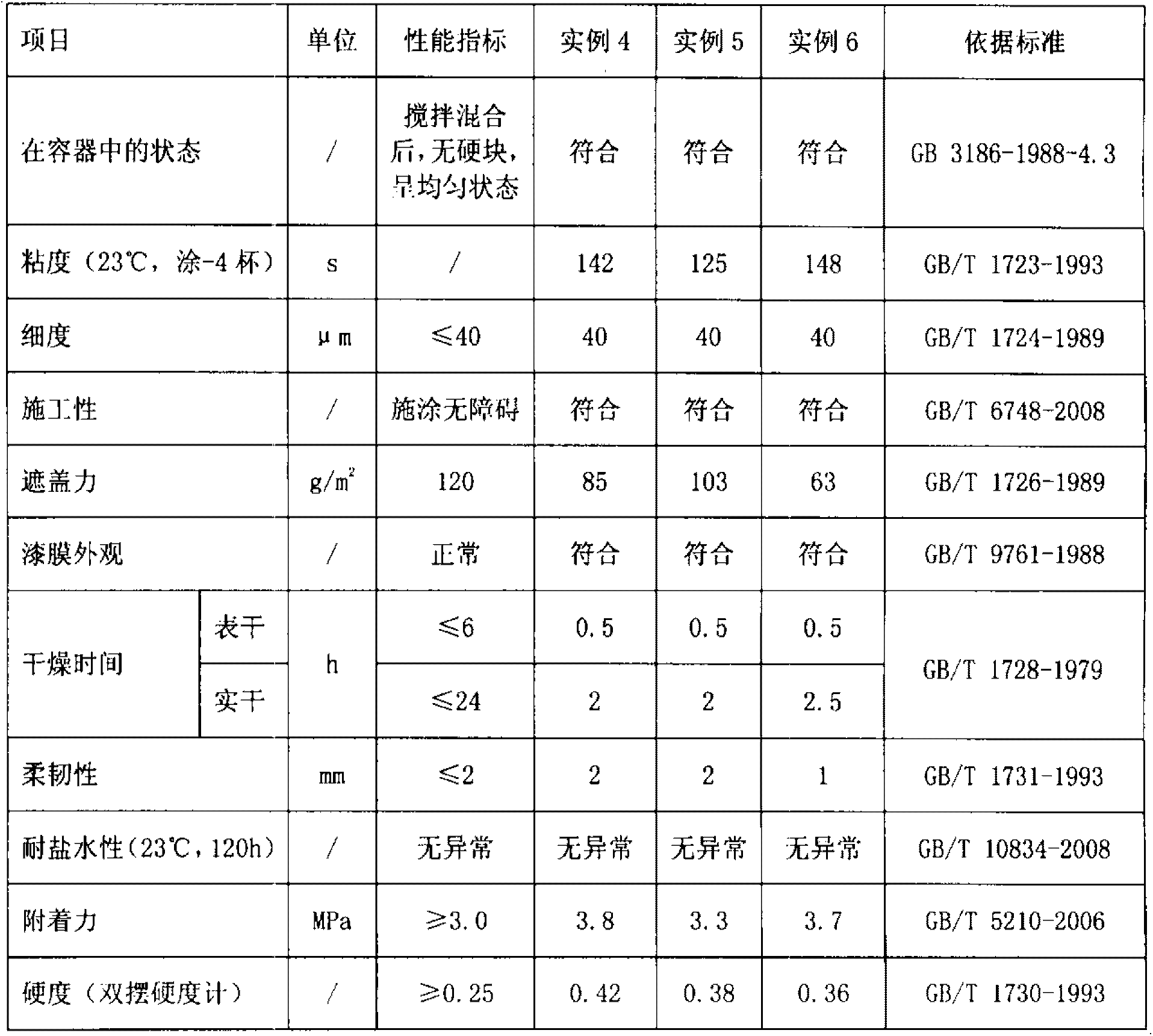

Examples

Embodiment 1

[0033] A kind of quick-drying bottom-surface-integrated steel structure paint, this steel structure paint is made of the following components and the raw materials of weight content content: synthetic resin 20 weight parts (among them, alkyd resin 8 weight parts, chlorinated rubber 7 weight parts , 5 parts by weight of acrylic resin); 10 parts by weight of antirust pigment (wherein, 9 parts by weight of aluminum tripolyphosphate, 1 part by weight of zinc oxide); 6 parts by weight of coloring pigment (wherein, 5.5 parts by weight of titanium dioxide, 0.5 parts by weight of carbon black 5 parts by weight of filler (wherein, 2 parts by weight of kaolin, 3 parts by weight of talcum powder); 1 part by weight of auxiliary agent (including 0.2 parts by weight of defoamer, 0.7 parts by weight of anti-settling agent and 0.1 part by weight of leveling agent, The defoamer is polydimethylsiloxane, the anti-settling agent is polyamide wax, and the leveling agent is polyether modified polydi...

Embodiment 2

[0041] A quick-drying steel structure paint with bottom surface integrated, the steel structure paint is made of the following components and raw materials in parts by weight: 38 parts by weight of synthetic resin (including 17 parts by weight of petroleum resin, 14 parts by weight of chlorinated rubber, 7 parts by weight of chlorinated paraffin; 20 parts by weight of antirust pigment (wherein, 15 parts by weight of zinc phosphate, 5 parts by weight of zinc oxide); 12 parts by weight of coloring pigment (wherein, 10 parts by weight of iron oxide red, 2 parts by weight of iron oxide yellow parts by weight); 11 parts by weight of filler (wherein 5 parts by weight of calcium carbonate, 6 parts by weight of barium sulfate); 4 parts by weight of additives (including 0.4 parts by weight of defoamer, 3.3 parts by weight of anti-settling agent and 0.3 parts by weight of leveling agent agent, the defoamer is polydimethylsiloxane, the anti-settling agent is organic bentonite, and the lev...

Embodiment 3

[0049] A kind of quick-drying type bottom-in-one steel structure paint, this steel structure paint is made of the following components and the raw materials of content by weight: synthetic resin 31 (wherein, alkyd resin 22 weight parts, chlorinated rubber 9 weight parts); Antirust pigment 15 (wherein, zinc phosphate 7 weight parts, aluminum tripolyphosphate 8 weight parts); Coloring pigment 9 weight parts (wherein, titanium dioxide 8 weight parts, phthalocyanine blue 1 weight part); Filler 8 weight parts (wherein , 3 parts by weight of mica powder, 5 parts by weight of talcum powder); 2.6 parts by weight of additives (including 0.2 parts by weight of defoamer, 0.4 parts by weight of anti-skinning agent, 1.8 parts by weight of anti-settling agent and 0.2 parts by weight of leveling agent, The defoamer is polydimethylsiloxane, the anti-skinning agent is methyl ethyl ketone oxime, the anti-settling agent is organic bentonite, and the leveling agent is polyether modified polydimeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com