Super-hydrophobic nano-silver raman-enhanced substrate material and preparation method thereof

A substrate material and nano-silver technology, which is applied in Raman scattering, material excitation analysis, metal material coating process, etc. Enhanced effect, not easy to deteriorate, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

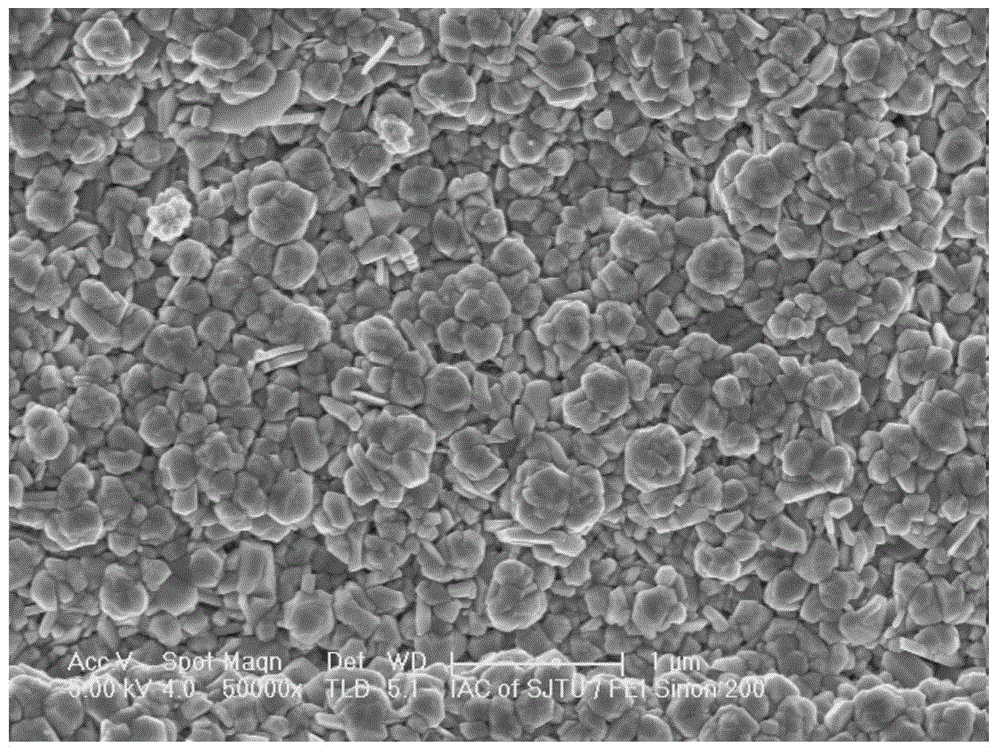

[0035] A copper sheet is selected as the metal substrate, and its surface is subjected to electrochemical degreasing and 20% sulfuric acid pickling treatment. Put the treated copper sheet in the chemical deposition solution for chemical deposition. The composition and concentration of the chemical deposition solution are: silver nitrate 0.08mol / L, ammonium citrate 0.08mol / L, boric acid 0mol / L, hypophosphorous acid Sodium 0mol / L, additive 0g, adjust pH to 7.5 with ammonia water, the temperature of chemical deposition is 80 ℃, and chemical deposition time is 10min, the rough nano-silver surface obtained is as follows figure 1 As shown, the particle size range of the rough nano-silver particles is between 100-500nm, and the distance between silver particles is 10-30nm, which can generate strong plasmon resonance. After storage for 1-2 months, the contact angle of water droplets on the surface is 150°. However, due to the poor uniformity of the particle size, the surface Raman enh...

Embodiment 2

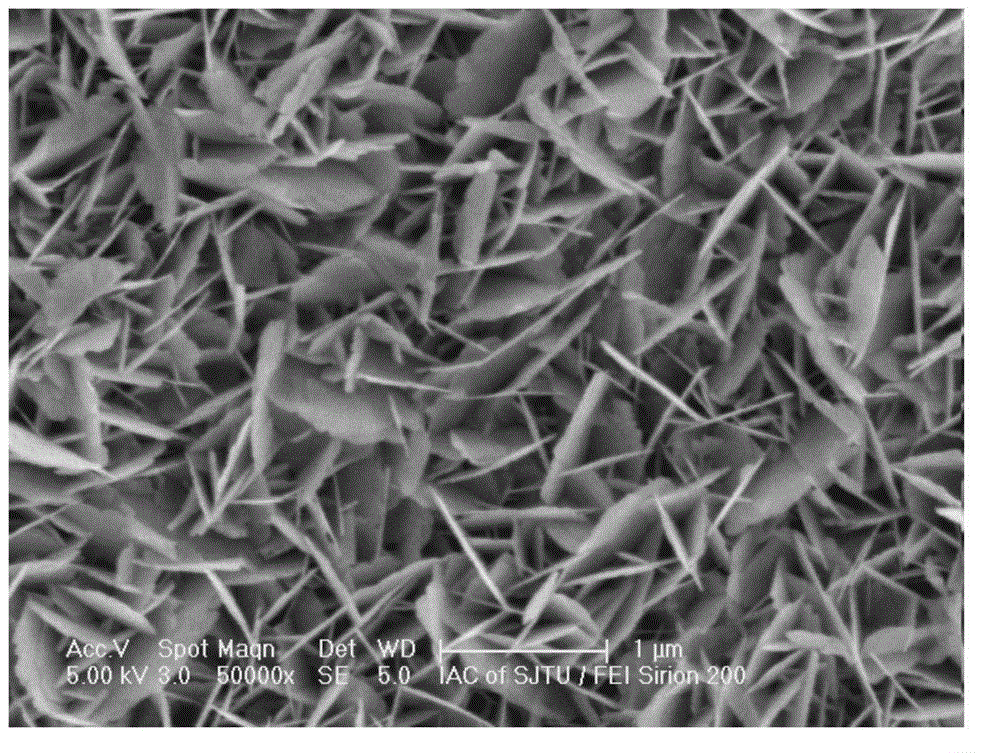

[0037] A copper sheet is selected as the metal substrate, and its surface is subjected to electrochemical degreasing and 20% sulfuric acid pickling treatment. Put the treated copper sheet in the chemical deposition solution for chemical deposition. The composition and concentration of the chemical deposition solution are: silver nitrate 0.08mol / L, malic acid 0.08mol / L, boric acid 4mol / L, sodium hypophosphite 0mol / L, adjust the pH to 8 with ammonia water, the temperature of chemical deposition is 20°C, and the chemical deposition time is 5min. The rough nano-silver surface obtained is as follows figure 2 As shown, the rough nano-silver has a slender sheet structure with a length of 0.5-1.0 μm, a thickness of 0.01-0.03 μm, and a silver particle spacing of 100-300 nm, which can generate strong plasmon resonance and can be stored for 1-2 days. After one month, the contact angle of water droplets on the surface is 154°. However, due to the large distance between particles and poor...

Embodiment 3

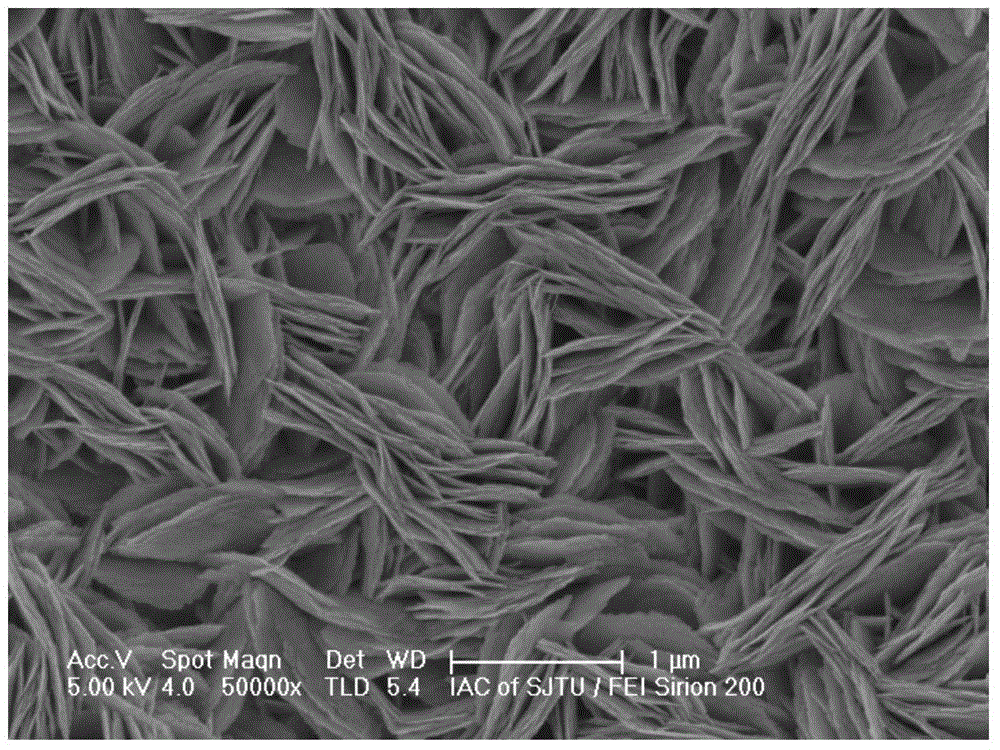

[0039]A copper sheet is selected as the metal substrate, and its surface is subjected to electrochemical degreasing and 20% sulfuric acid pickling treatment. Put the treated copper sheet in the chemical deposition solution for chemical deposition. The composition and concentration of the chemical deposition solution are: silver nitrate 0.08mol / L, ammonium citrate 0.08mol / L, boric acid 4mol / L, hypophosphorous acid Sodium 0.2mol / L, polyvinyl alcohol 3g / L, adjust the pH to 8 with ammonia water, the temperature of chemical deposition is 50 ℃, and the chemical deposition time is 30min, the obtained rough nano-silver surface is as follows: image 3 As shown, the rough nano-silver is in an elongated sheet-like structure with a length of 1-1.5 μm, a thickness of 0.01-0.02 μm, and a silver particle spacing of 50-200 nm, which can generate strong plasmon resonance and can be stored for 1-2 After one month, the contact angle of water droplets on the surface is 156°, the distance between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com