Method for manufacturing all-solid visualized taste sense sensor array

The technology of a taste sensor and its production method is applied in the direction of material analysis by observing the influence on chemical indicators, and analysis by chemical reaction of the material, etc., which can solve the complex preparation steps of the visual sensor array, reduce the sensitivity of the visual sensor array, Chemical substances can not react and other problems, to achieve the effect of improved consistency, low cost, and improved detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

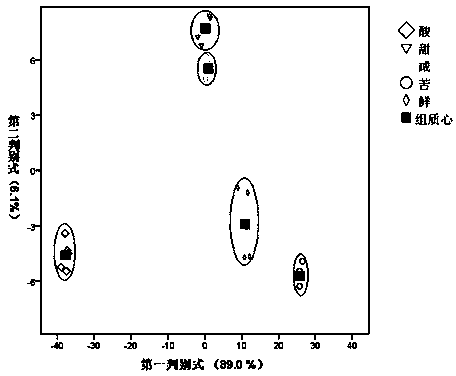

[0020] The method for making the all-solid-state taste visualization sensor array of the present invention will be described in more detail below in conjunction with the accompanying drawings:

[0021] (1) Selection of color-sensitive materials for all-solid-state taste visualization sensors: Hydrophobic porphyrin compounds that have color responses to trace chemical substances in liquid samples were selected as sensor color-sensitive materials. After several pre-tests, tetraphenylporphyrin, 5,10,15,20-tetraphenyl-porphine manganese chloride, 2,3,7,8,12,13,17,18-octa Ethyl-porphine manganese chloride, 5,10,15,20-tetraphenyl-porphine copper, 5,10,15,20-tetraphenyl-porphine zinc, 5,10,15,20-tetraphenyl (Pentafluorophenyl)-porphine iron chloride, 5,10,15,20-tetraphenyl-porphine iron chloride, 5,10,15,20-tetraphenyl-porphine cobalt and 2,3 ,9,10,16,17,23,24-Octa(octyloxy)-zinc phthalocyanine as a color-sensitive material for taste-visualized sensor arrays.

[0022] (2) Selection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com