BMN dielectric film microwave voltage-controlled capacitor preparation method

A dielectric thin film and capacitor technology, applied in voltage variable capacitors, etc., can solve problems such as chemical mismatch, achieve high quality factor, moderate tuning rate, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

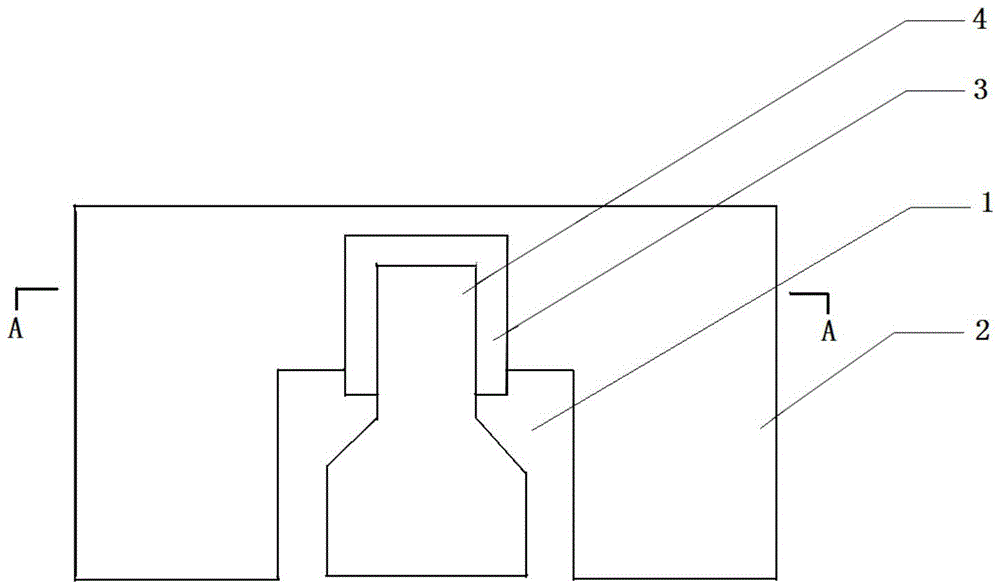

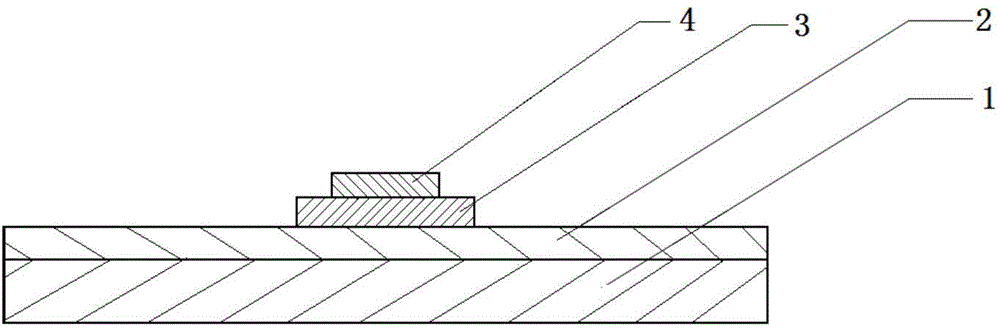

Image

Examples

Embodiment 1

[0056] (1) Preparation of the bottom electrode

[0057] (1) cleaning the substrate;

[0058] Choose a silicon oxide sheet (SiO 2 / Si) as the substrate, ultrasonically cleaned with deionized water for 10 min, ultrasonically cleaned with acetone for 10 min, ultrasonically cleaned with alcohol for 10 min, and then ultrasonically cleaned with deionized water for 10 min on SiO 2 / Si substrate is cleaned, and the substrate is dried quickly after cleaning;

[0059] (2) Spin-on photoresist

[0060] SiO 2 The / Si substrate is vacuum adsorbed on the adsorption table of the homogenizer, and the photoresist is dropped on the center of the substrate; the rotation speed is selected as 1500 rpm, and the holding time is 10 seconds, and the photoresist is evenly coated on the surface of the substrate , forming a good contact; the obtained photoresist was tested by a D-100 step meter, and the thickness of the photoresist coating was 2 μm;

[0061] (3) Pre-baking

[0062] Place the substra...

Embodiment 2~5

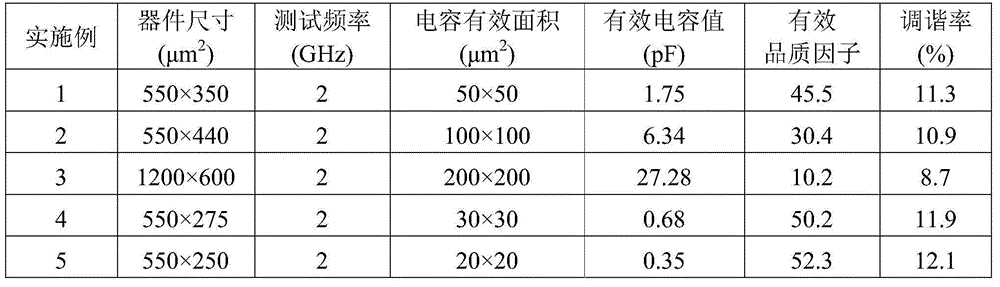

[0096] The preparation steps of Examples 2-5 are the same as those of Example 1, except that the device size and the effective area of the capacitor are different. The distinguishing features of each example and their related microwave properties are shown in Table 1.

[0097] Table 1

[0098]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com