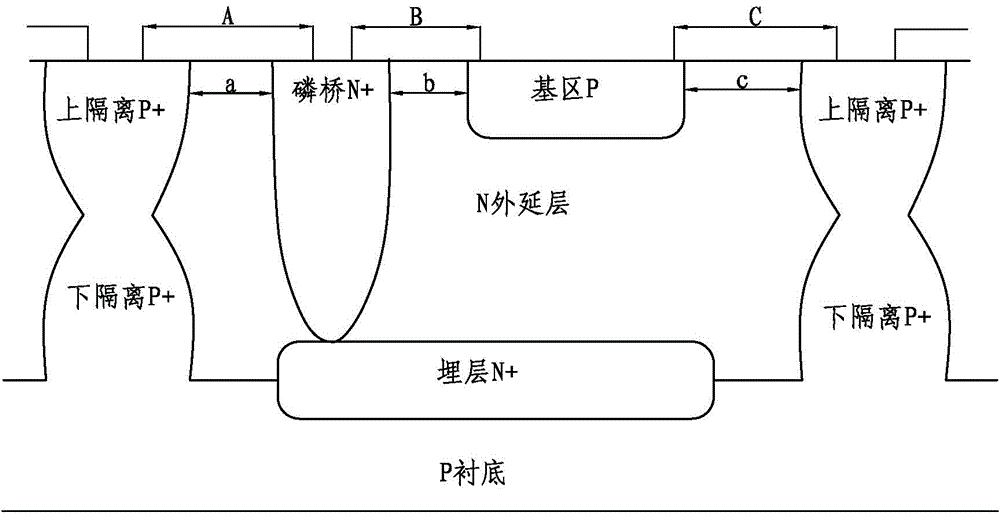

Bipolar integrated circuit chip based on groove dielectric isolation and production technology thereof

An integrated circuit, dielectric isolation technology, applied in circuits, electrical components, transistors, etc., can solve the problems of increasing the size of lateral diffusion, increasing the design size of products, and high cost of a single die, reducing the dependence on design size and improving products. Competitiveness, the effect of preventing premature breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A bipolar integrated circuit chip production process based on trench dielectric isolation, comprising the following steps:

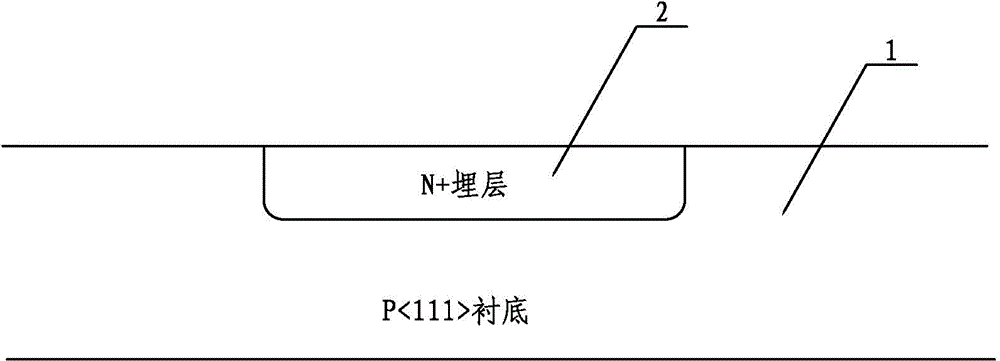

[0038] 1) Formation of N+ buried layer 2: coating of antimony source on silicon substrate 1, photolithography of N+ buried layer pattern, and high-temperature diffusion of N+ buried layer 2, and finally removal of all silicon surface oxide layers, such as figure 2 As shown; the thickness of the silicon substrate 1 is 400-600 microns, and in this embodiment, the thickness of the silicon substrate 1 is 500 microns;

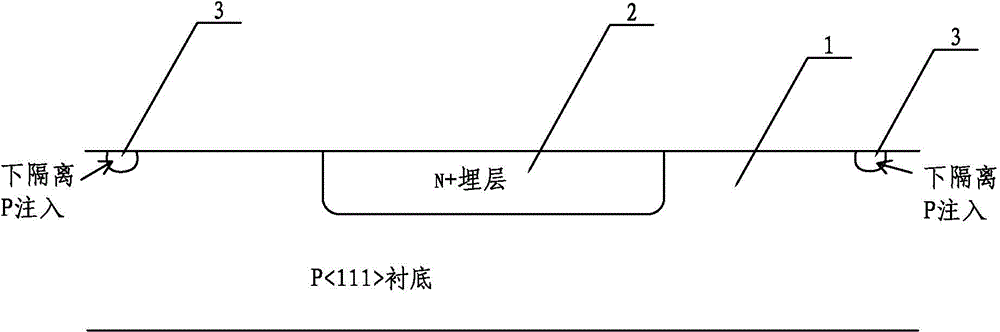

[0039] 2) Formation of the lower isolation region 3: Form the lower isolation photolithographic pattern on the silicon substrate 1, implant P-type impurities in the lower isolation region 3, and remove the glue after implantation, such as image 3 shown;

[0040]3) Formation of the epitaxial layer 4: the epitaxial layer 4 is grown on the upper surface of the silicon substrate 1 forming the lower isolation region 3, the thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com