Method for preparing fuel by synchronously electrolyzing water vapor at high temperature and oxidizing methane

A technology of high-temperature electrolysis and water vapor, applied in chemical instruments and methods, fuel cells, electrolysis processes, etc., can solve the problems of difficult control of the thickness of the active layer, uneven distribution of active agents, loss of activity of active agents, etc., to achieve low cost, The effect of easy operation and no exhaust emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

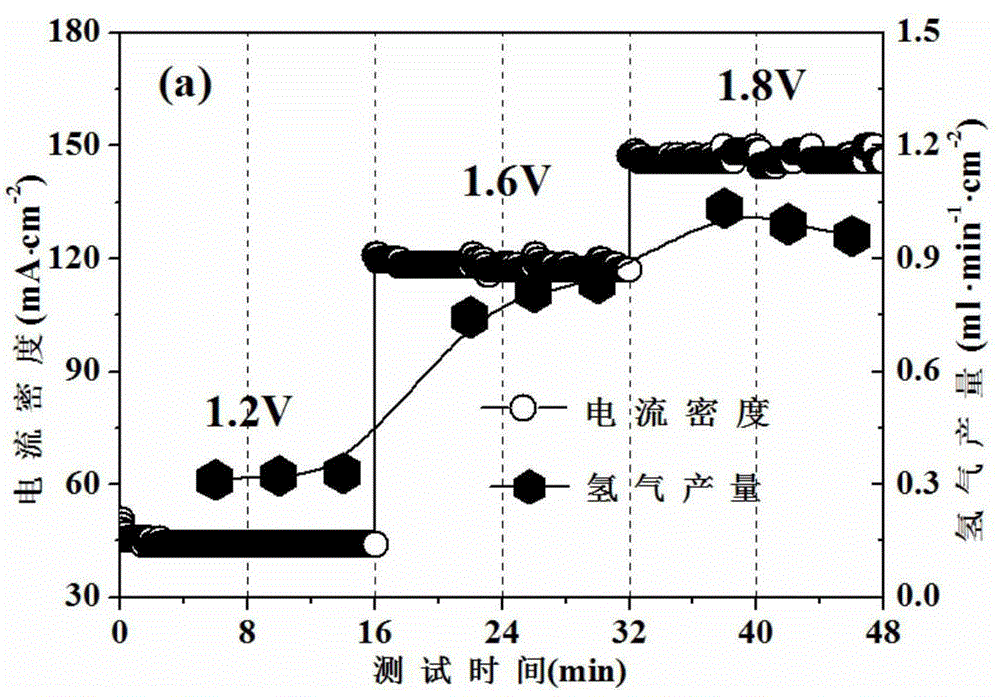

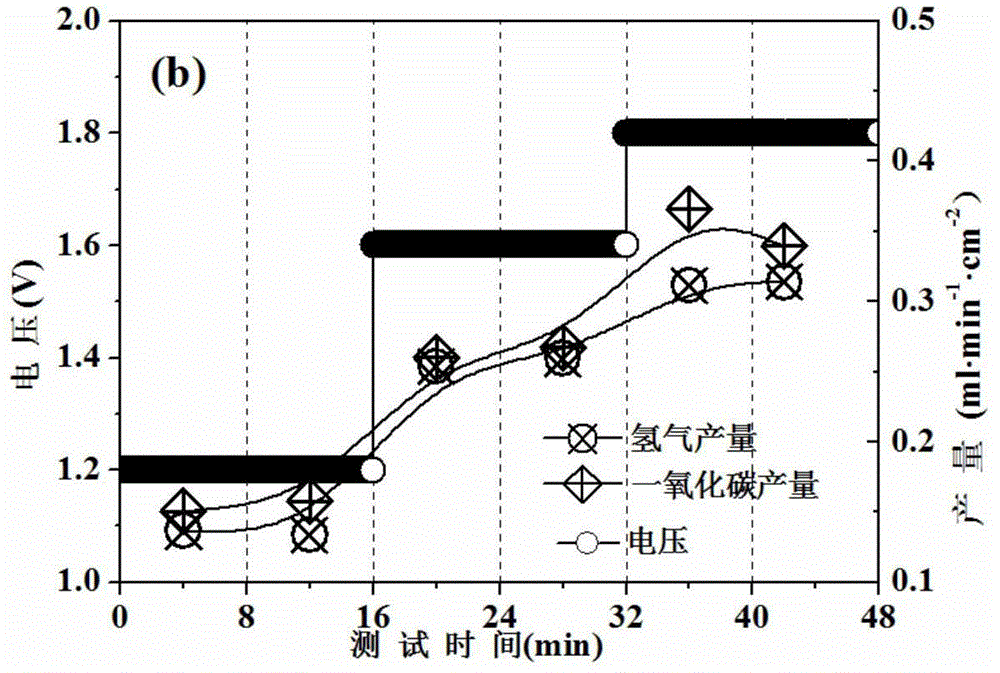

[0021] Example 1: Synchronous electrolysis of water vapor to oxidize methane at 800°C to prepare fuel

[0022] In this embodiment, high-temperature electrolysis of water vapor and synchronous oxidation of methane to prepare fuel are carried out according to the following steps:

[0023] (1) The 8YSZ dense electrolyte with a thickness of 200 microns and the porous 8YSZ layer with a thickness of 50 microns and a porosity of 40% were prepared by casting method, and the 8YSZ dense electrolyte was used as the middle layer, and the porous 8YSZ layer was used as both side layers, Construct a three-layer homogeneous YSZ ceramic sheet as a single cell support;

[0024] (2) respectively by dipping La 0.75 Sr 0.25 Cr 0.5 Fe 0.5 o 3-δ Nanoparticles are loaded onto the porous YSZ layer on both sides of the three-layer homogeneous YSZ ceramic sheet to construct a composite anode and composite cathode, and then heat-treated at 650°C for 30 minutes to remove organic matter and obtain a s...

Embodiment 2

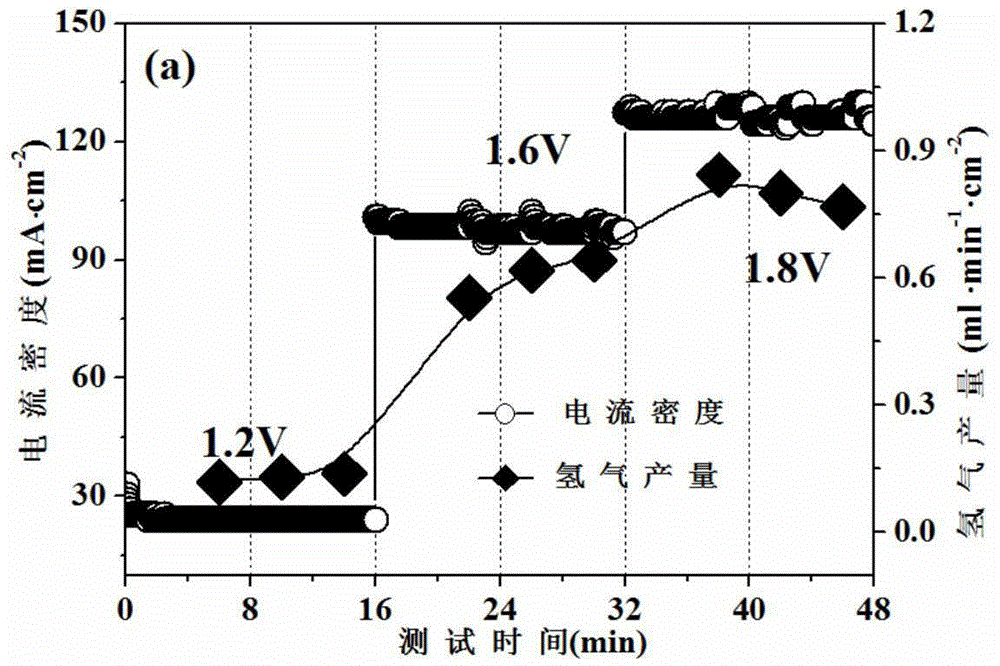

[0033] Example 2: Synchronous electrolysis of water vapor to oxidize methane at 700°C to prepare fuel

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com