Method for preparing environmental-friendly type gel profile control agent

A profile control agent and an environment-friendly technology, which is applied in the field of preparation of an environment-friendly gel profile control agent, can solve the problems of increasing the load of a dehydration station, environmental pollution, environmental impact, etc., and achieves low cost, reduced production cost, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of an environment-friendly gel profile control agent, the preparation steps are as follows:

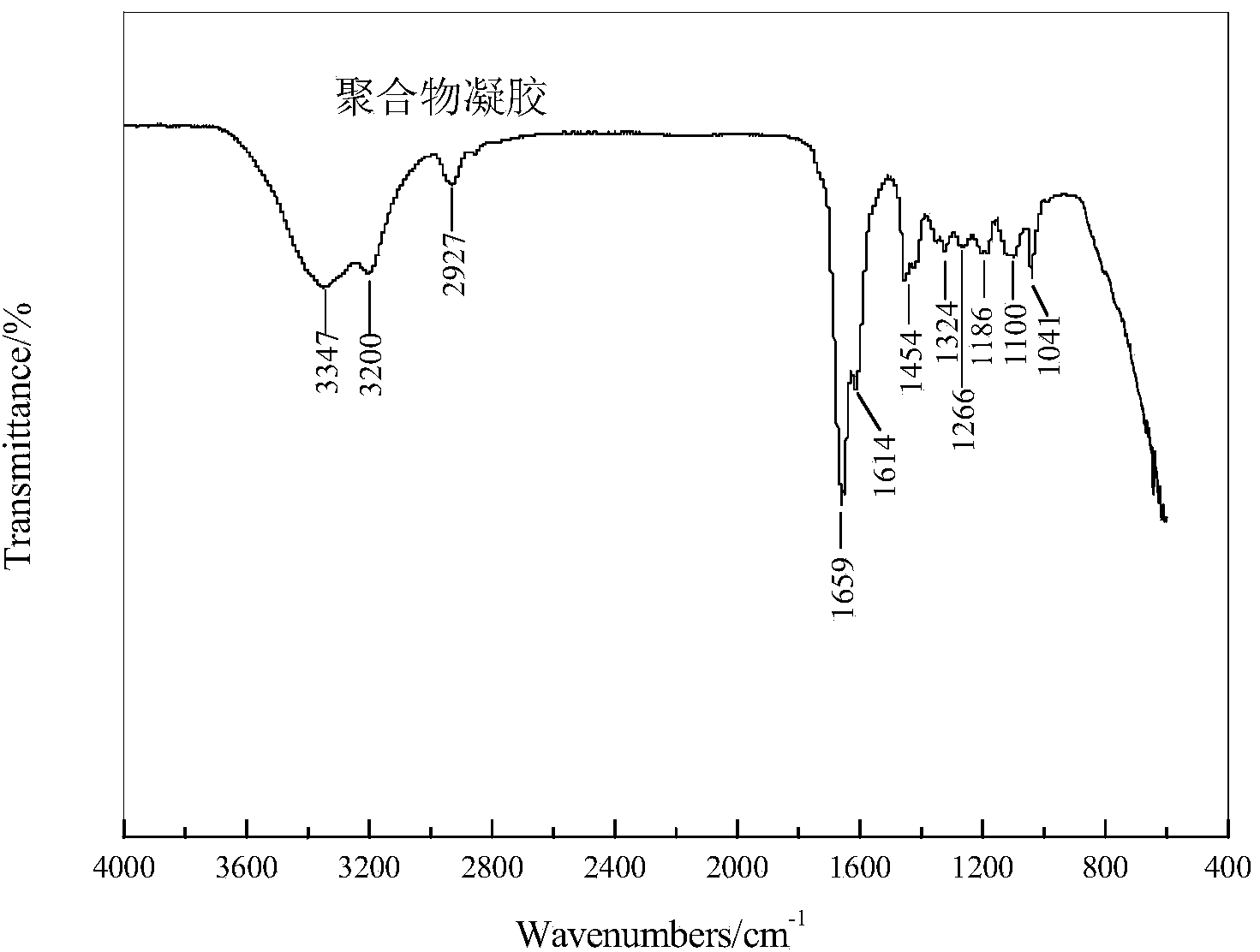

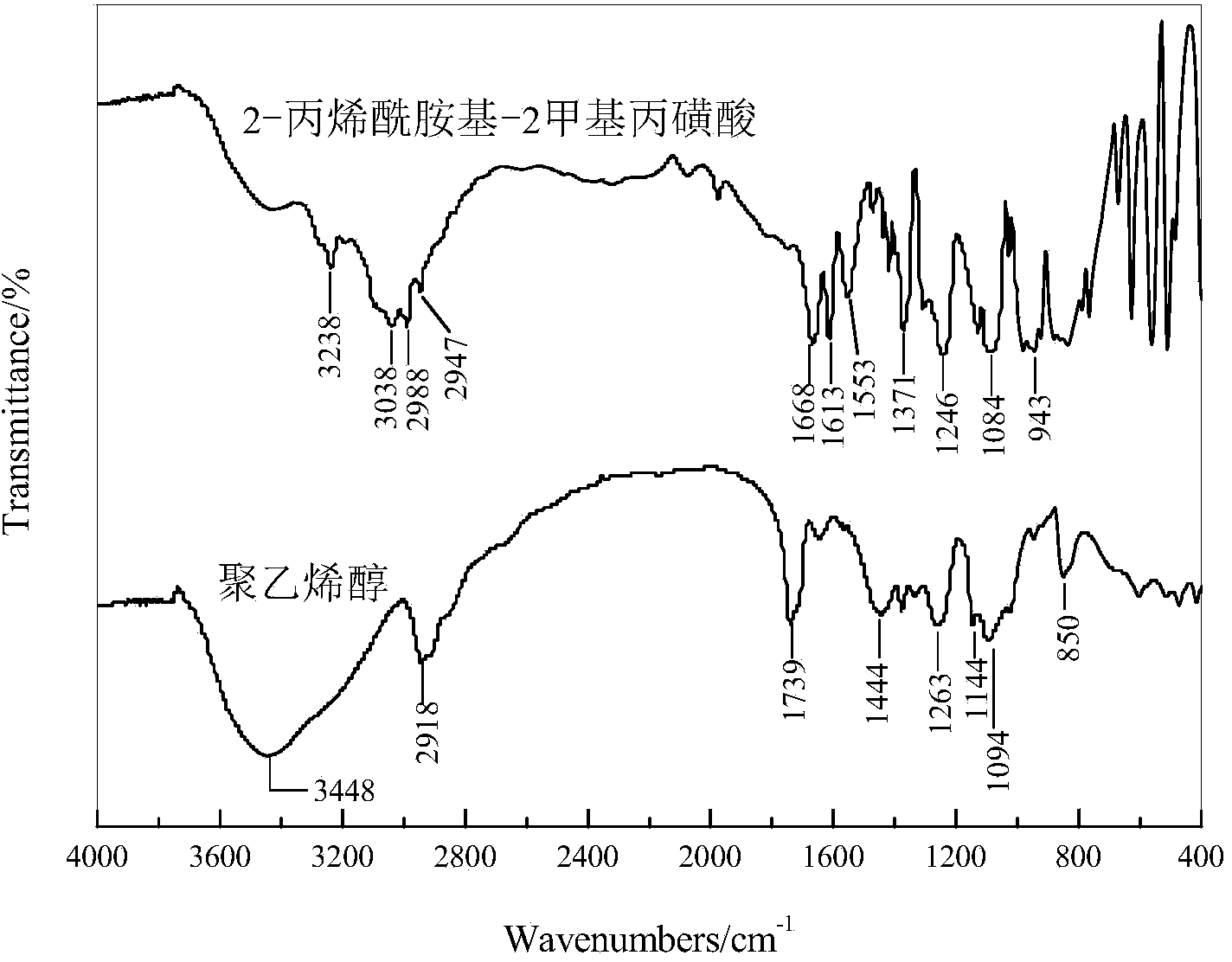

[0024] After completely dissolving 5g of acrylamide, 0.0015g of N,N'-methylenebisacrylamide and 0.5g of 2-acrylamido-2-methylpropanesulfonic acid in 70mL of distilled water, add 0.025g (NH 4 ) 2 S 2 o 8 , and carry out polymerization reaction at 60° C. in a nitrogen-enclosed atmosphere to form a prepolymer. Then 2g of polyvinyl alcohol PVA-1788 was completely dissolved with 30mL of distilled water, and the polyvinyl alcohol solution, 0.0015g of N,N'-methylenebisacrylamide and 0.025g of (NH 4 ) 2 S 2 o 8 Add it to the prepolymer, and continue the reaction at 80°C in a nitrogen-enclosed atmosphere until the reaction is complete to obtain a gel profile control agent. After purification and drying of the gel profile control agent and the raw materials 2-acrylamide-2-methylpropanesulfonic acid and polyvinyl alcohol, the infrared test was carried out to ob...

Embodiment 2

[0027] After completely dissolving 5g of acrylamide, 0.0015g of N-methylolacrylamide and 0.5g of styrenesulfonic acid in 70mL of distilled water, add 0.025g of K 2 S 2 o 8 , and carry out polymerization reaction at 60° C. in a nitrogen-enclosed atmosphere to form a prepolymer. Then 2g of polyvinyl alcohol PVA-1795 was completely dissolved with 30mL of distilled water, and the polyvinyl alcohol solution, 0.0015g of N-methylolacrylamide and 0.025g of K 2 S 2 o 8 Add it to the prepolymer, and continue the reaction at 80°C in a nitrogen-enclosed atmosphere until the reaction is complete to obtain a gel profile control agent.

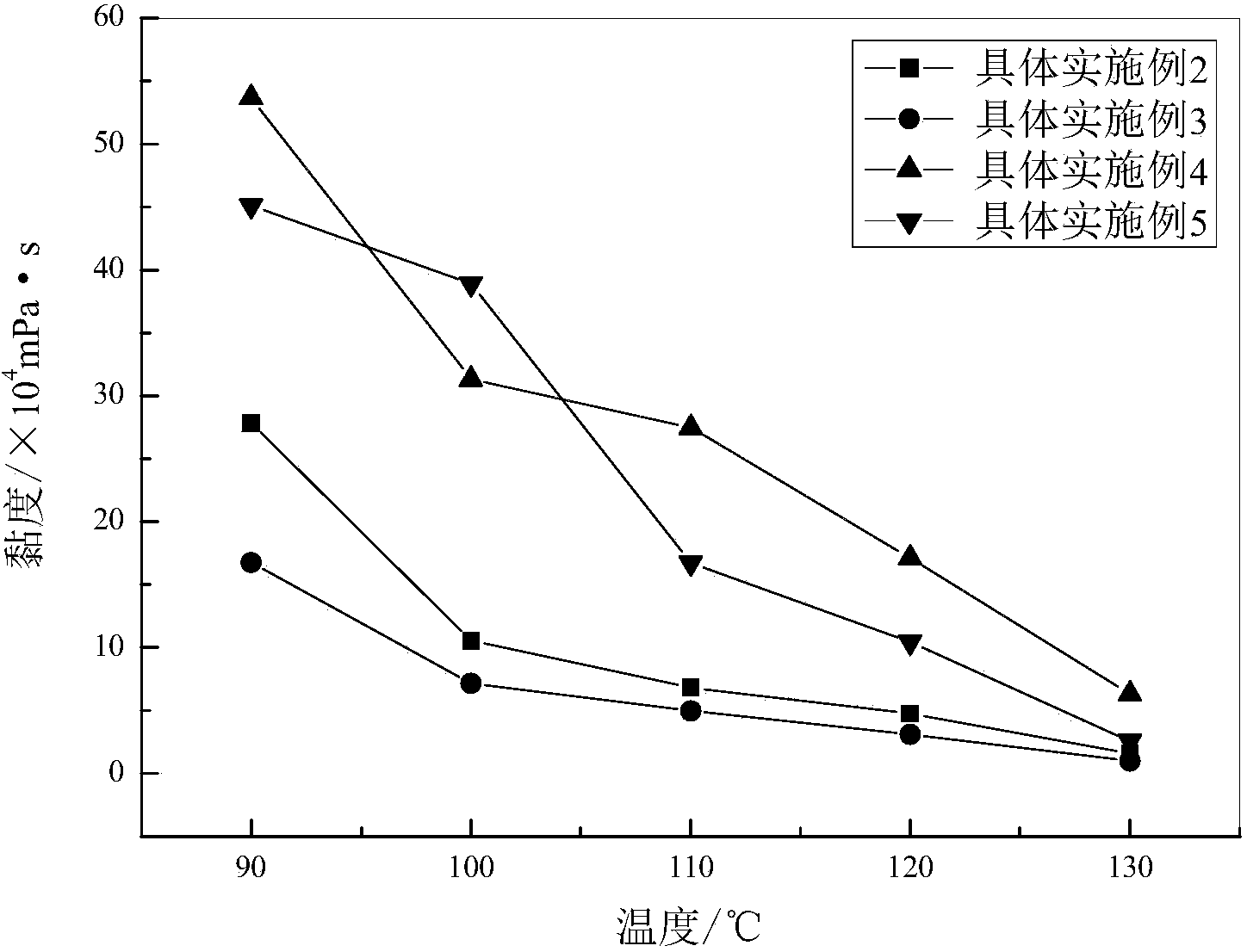

[0028] During the test, the viscosity of the gel was measured with an NDJ-8S viscometer, and the temperature and salt resistance properties are shown in the attached image 3 And attached Figure 5 As shown, the temperature resistance range is 90-130°C; the applicable crude salt concentration range is 0-25% (by weight of the prepared profile control ag...

Embodiment 3

[0032] After completely dissolving 5g of acrylamide, 0.0025g of N-methylolacrylamide and 0.5g of styrenesulfonic acid in 70mL of distilled water, add 0.025g of K 2 S 2 o 8 , and carry out polymerization reaction at 60° C. in a nitrogen-enclosed atmosphere to form a prepolymer. Then 2g of polyvinyl alcohol PVA-1795 was completely dissolved with 30mL of distilled water, and the polyvinyl alcohol solution, 0.0025g of N-methylolacrylamide and 0.025g of K 2 S 2 o 8 Add it to the prepolymer, and continue the reaction at 80°C in a nitrogen-enclosed atmosphere until the reaction is complete to obtain a gel profile control agent.

[0033] During the test, the viscosity of the gel was measured with an NDJ-8S viscometer, and the temperature and salt resistance properties are shown in the attached image 3 And attached Figure 5 As shown, the temperature resistance range is 90-130°C; the applicable crude salt concentration range is 0-25% (by weight of the prepared profile control ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com